Periodic metal/dielectric structural photon crystal with three-dimensional band gap and preparing mehtod thereof

A photonic crystal, dielectric structure technology, applied in optics, electrical components, optical components, etc., to achieve the effect of reducing quality and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

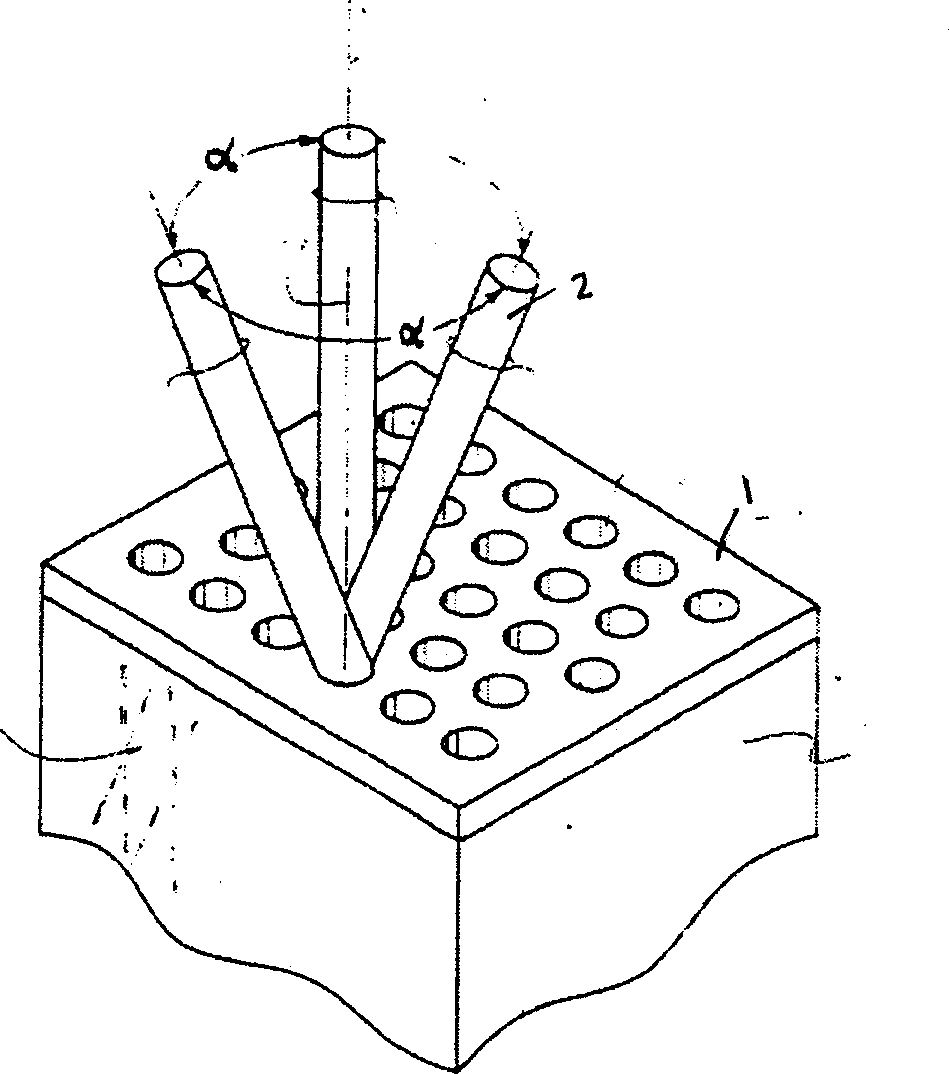

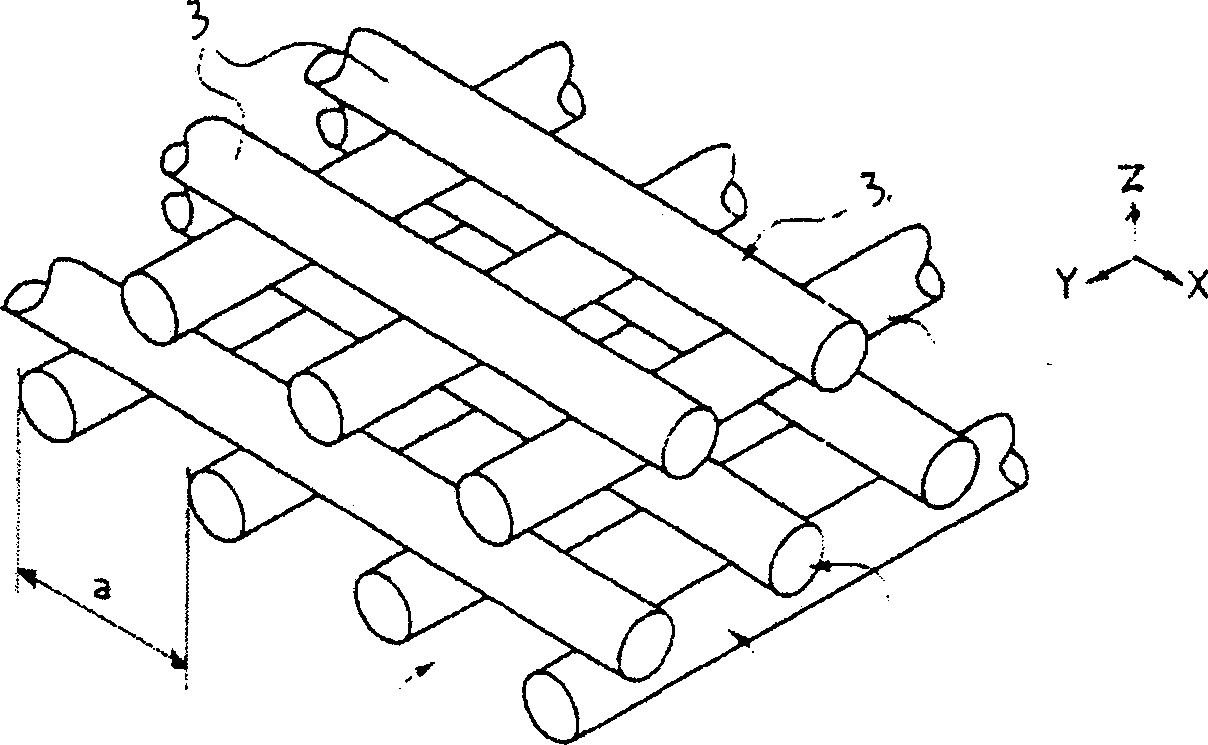

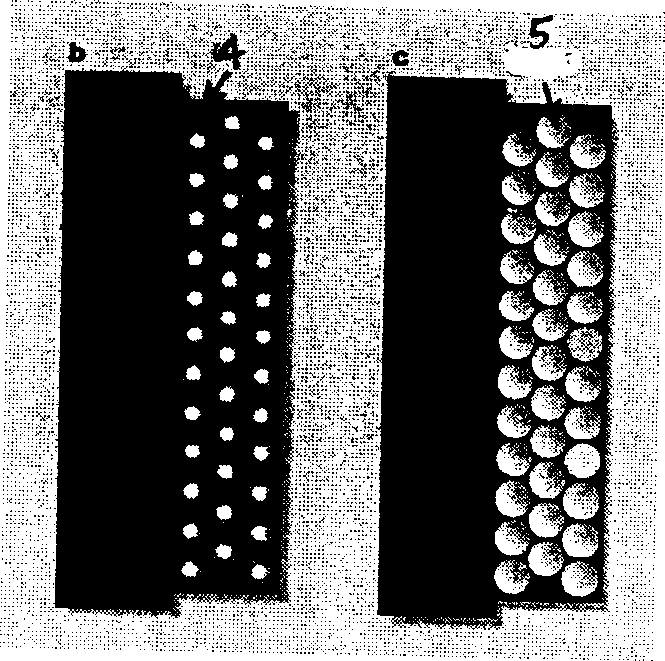

[0039] The most basic unit of the three-dimensional full-bandgap photonic crystal of the present invention is a compound dielectric sphere composed of metal and dielectric material. The schematic diagram of its internal structure is shown in Figure 3A and 4A .

[0040] In the present invention, by implementing a dielectric coating on the surface of a solid metal sphere, a Figure 3A Composite media spheres are shown.

[0041] In the present invention, monodisperse colloidal spheres (such as polystyrene or silicon dioxide) are adopted as the support core, and at first the surface is passed through existing chemical methods: these methods mainly include: surface seed growth technology, referring to S.J.Oldenburg, R.D.Averitt, S.L.Westcott, N.J.Halas, Chem.Phys.Lett.1998, 288, 243; Surface Deposition Reaction Technology, see L.M.Liz-Marzán, M.Giersig, P.Mulvaney, Langmuir 1996, 12, 4329; Surface Chemistry Methods Treatment and Function For mass adsorption methods, see S.L. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com