Prepn of faintly alkaline alkylbenzene sulfonate

A technology of alkylbenzene sulfonate and heavy alkylbenzene, which is applied in chemical instruments and methods, organic chemistry, chemical/physical processes, etc., and can solve problems such as equipment and pipeline corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] Get 300 grams of cut heavy alkylbenzene raw material, heat to 37 ℃ in the reactor of 1000ml, under the condition of stirring, dropwise add 20% (weight percent) SO 3 oleum or liquid SO3 dissolved in a solvent, reacted for 4 hours; then neutralized to a pH value of 7 with 20% (percentage by weight) of NaOH, then divided acid or desolvated to obtain heavy alkylbenzene sulfonate monomer, then add 10% (weight percent) dodecabranched alkylbenzene, 0-5% (weight percent) nonionic surfactant and 20% (weight percent) polar solvent in the monomer to obtain A weakly alkalized alkylbenzene sulfonate surfactant for tertiary oil recovery with an active substance content of 50% (weight percentage).

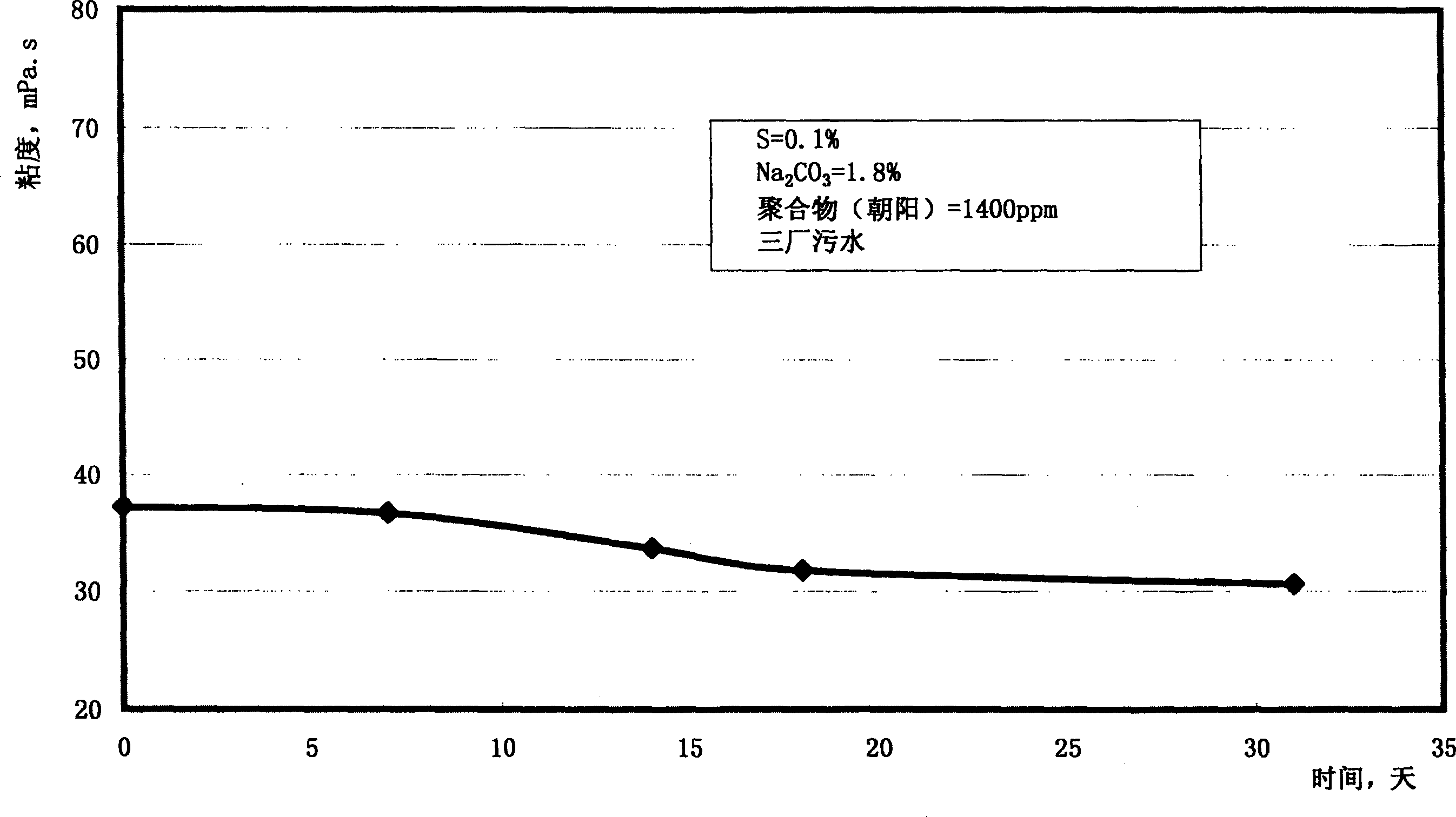

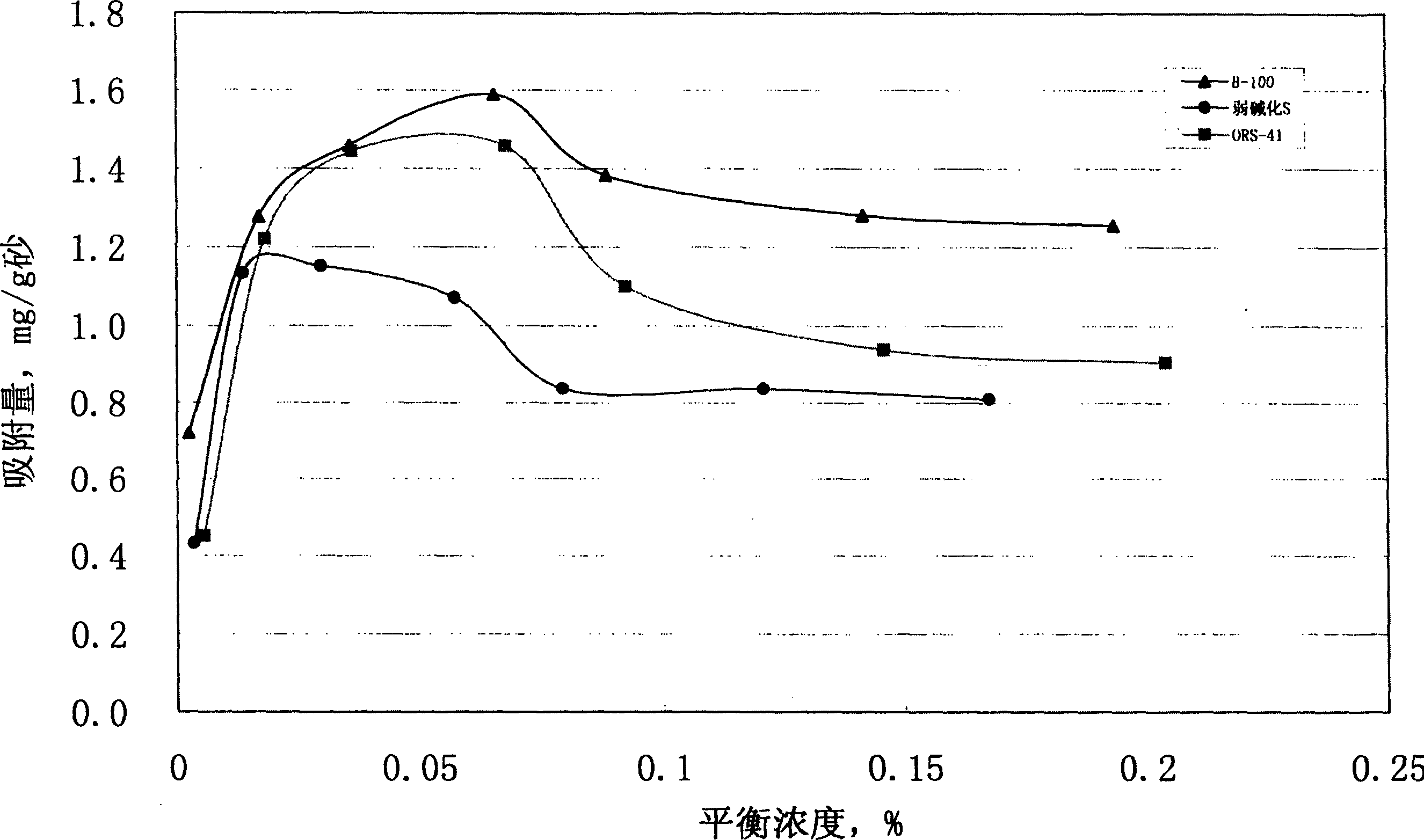

[0021] Below is the conclusion obtained by experiment of weakly alkalized alkylbenzene sulfonate of the present invention:

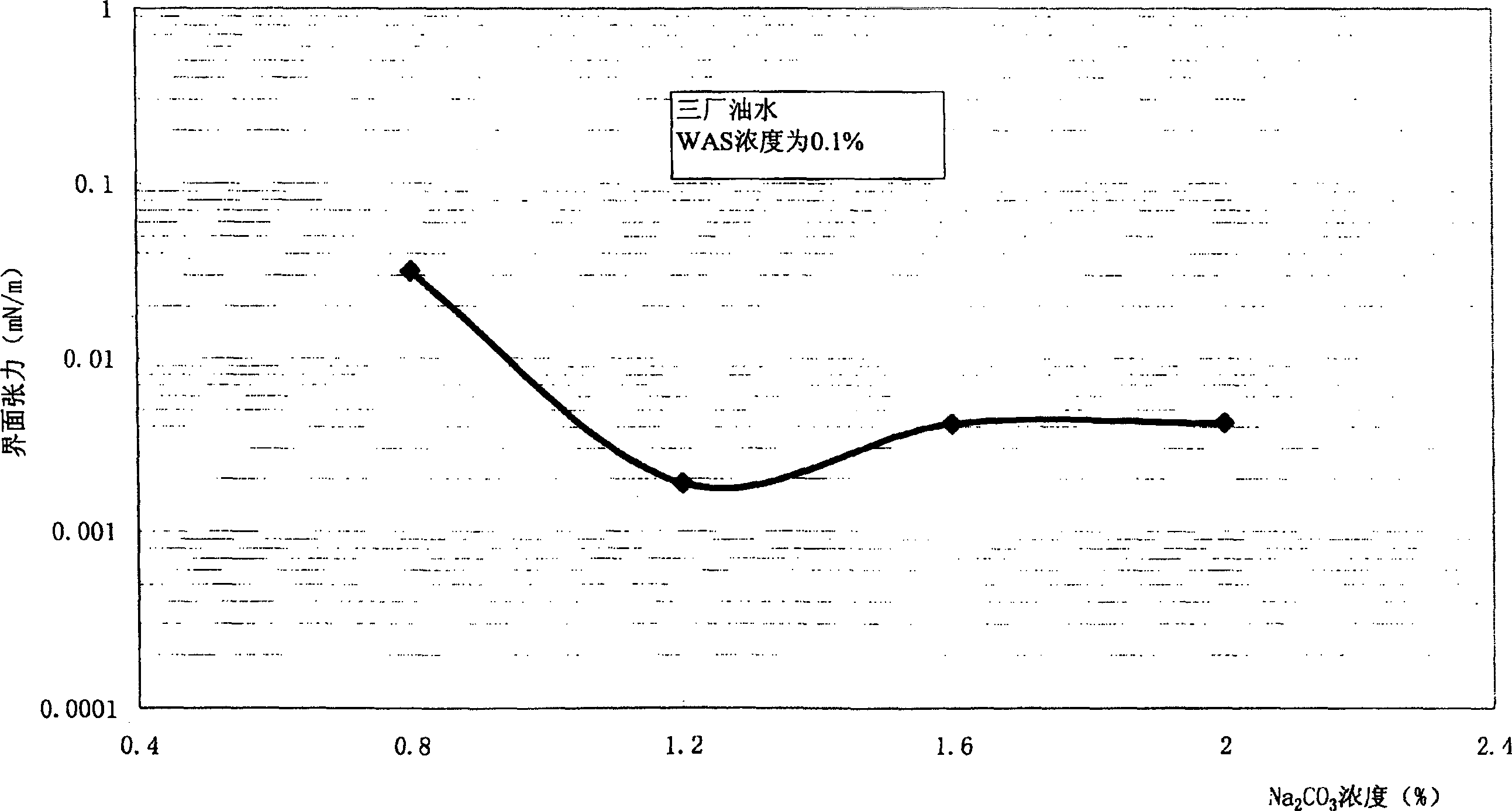

[0022] 1. Performance evaluation of interfacial tension

[0023] refer to figure 1 , the experimental conclusion shows that within a wide concentration range of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com