Sensor of chip contaonong microelectrode array

A micro-electrode array, chip sensor technology, applied in the direction of instruments, material capacitance, material electrochemical variables, etc., can solve the problems of not using electrochemical detection, the limitation of the object to be analyzed, and the high cost of the chip, and improve the detection sensitivity and film thickness. Uniform, controllable and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

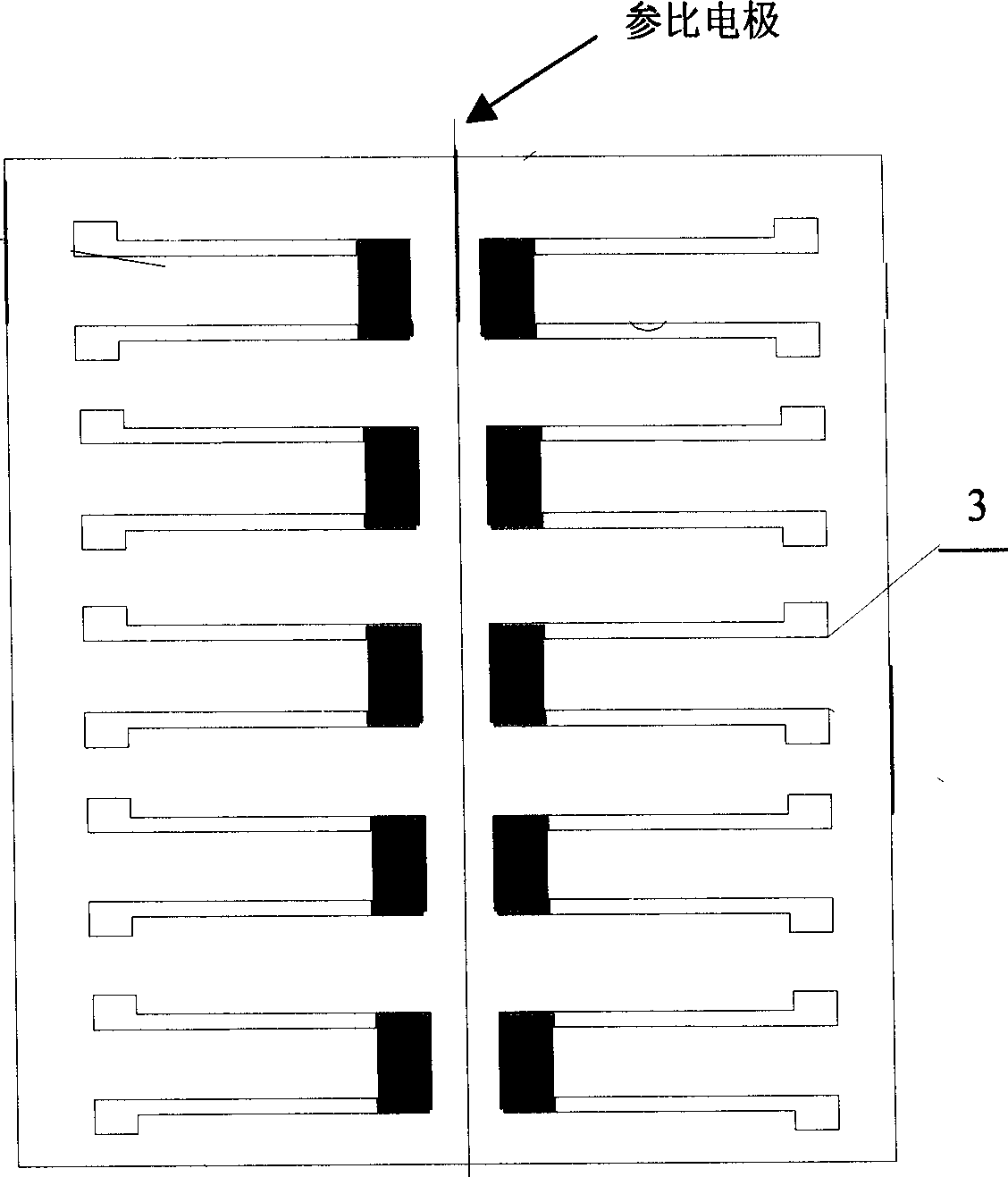

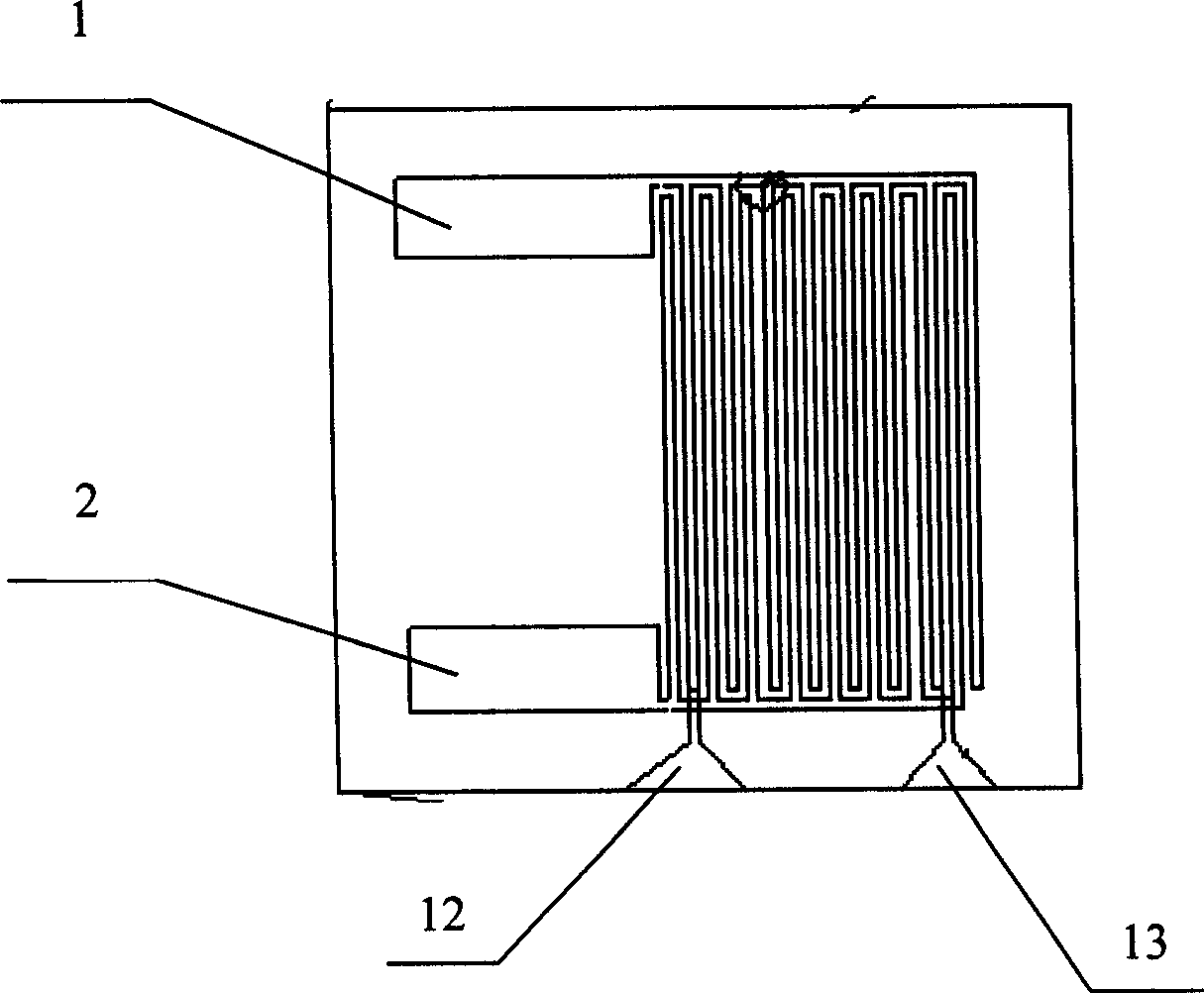

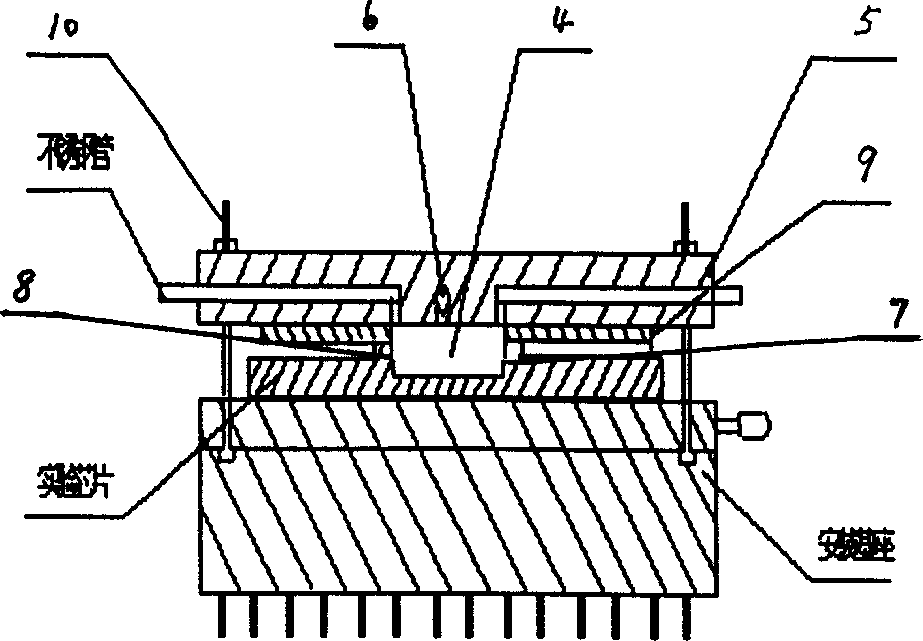

[0032] The base material of the microchip is a piece of n-type or p-type 100 monocrystalline silicon with a size of 3 cm in length and 2.0 cm in width. A layer of metal titanium film with a thickness of 100nm can be prepared on the surface of the silicon chip by vacuum evaporation method by means of physical surface film formation, and then a gold film with a thickness of 300nm can be prepared on it by the same method. The micro-electrode array designed according to needs is made into a negative photomask, and the metal layer (titanium and gold layer) on the part not covered by the mask is removed by photoetching technology. Then, a silicon dioxide insulating layer with a thickness of 150 nm is prepared by using a plasma enhanced chemical deposition method (PECVD, Plasma Enhance Chemical Vapor Deposition) at the position where the metal layer is removed. Then, the entire chip is annealed at a high temperature of 500 degrees for 30 minutes in an oxygen atmosphere. The lead-out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com