Application of zeolite molecular sieve film in the separation of ethylidene dichloride-nitrogen mixture

A technology of zeolite molecular sieve membrane and dichloroethane, applied in the field of chemical engineering, can solve the problems of restricting industrial application, high energy consumption of high temperature desorption, bulky equipment, etc., and achieve the effect of simple equipment, energy saving and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

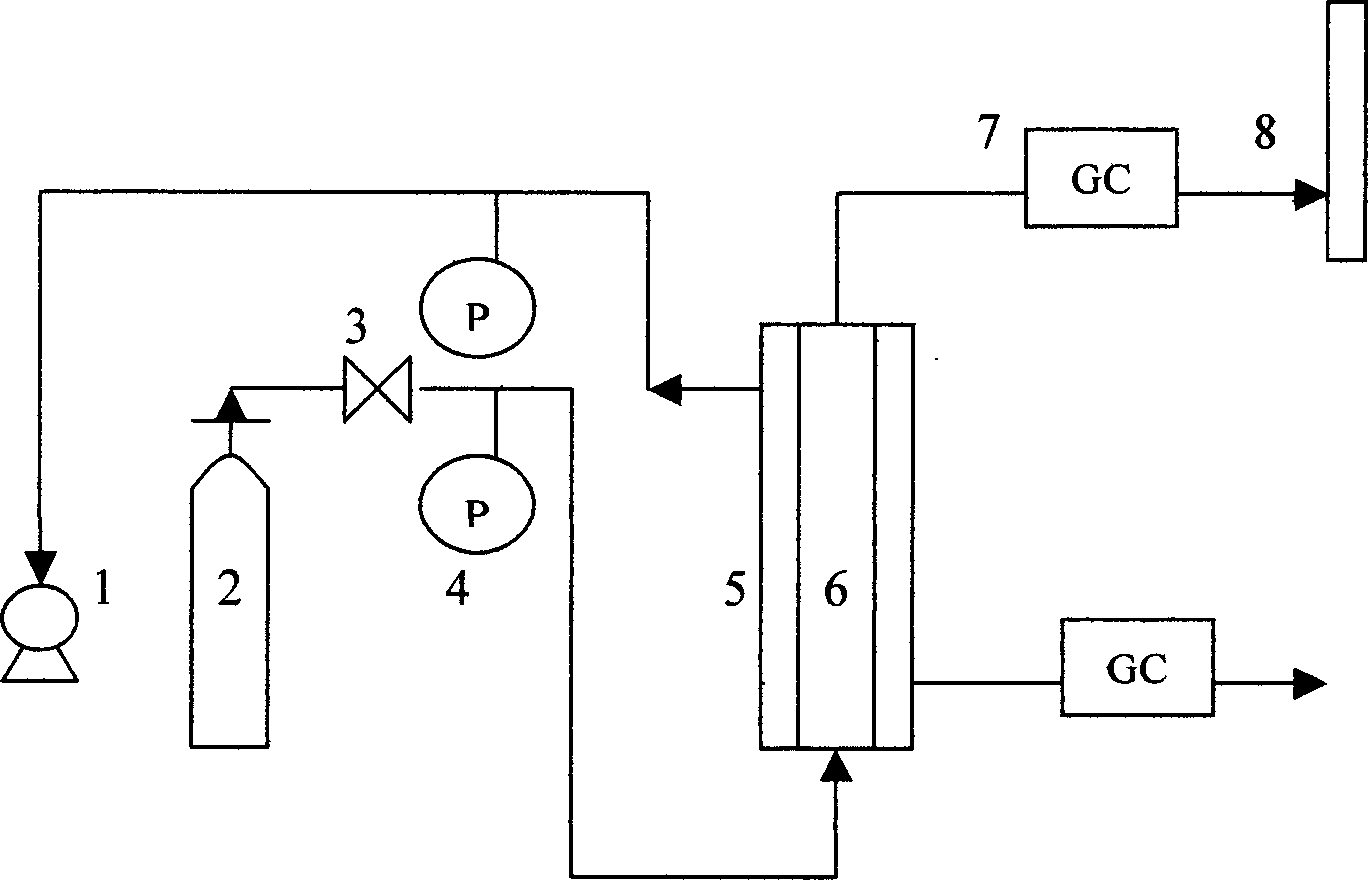

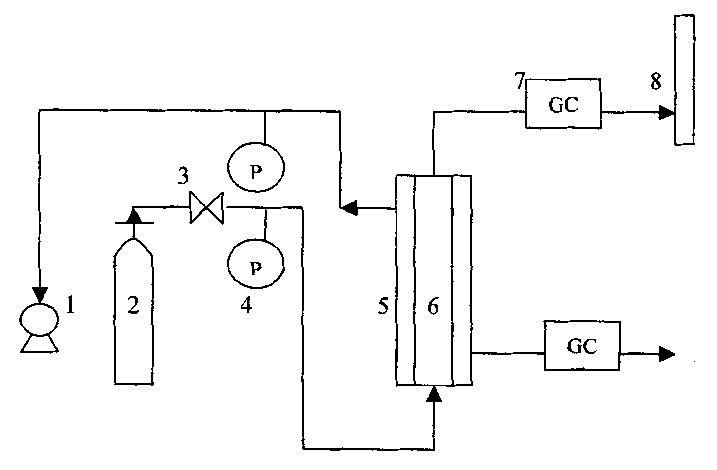

Method used

Image

Examples

Embodiment

[0015] Preparation of sol: Add 32g sodium hydroxide and 100ml water into a 400ml beaker, fully dissolve and add 44.8ml silica sol under vigorous stirring to obtain solution (a), then dissolve 16.7g aluminum sulfate in 110ml water to obtain solution (b) , and then slowly add the solution (b) dropwise to the solution (a) to form a white sol.

[0016] Carrier pretreatment: before synthesis, smooth the surface of the carrier with 400#, 600#, 800# sandpaper, then use ultrasonic vibration to wash away the suspended particles on the surface and pores, then soak in acid or alkali for 1-2 days, and ultrasonically wash until Neutral, tumble dry ready to use.

[0017] Membrane preparation: take the pretreated carrier tube, soak the surface of the carrier tube with citric acid, seal both ends of the tube with polytetrafluoroethylene film after treatment, put it vertically into a stainless steel crystallization kettle, and spread the sol along the tube wall Slowly add it into the kettle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com