Clamping casting type combined branch cable and making method thereof

A branch cable, cable technology, applied in cable/conductor manufacturing, insulated cables, cables, etc., can solve the problems of cable detachment and small contact area, and achieve the effect of enhanced tensile force and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

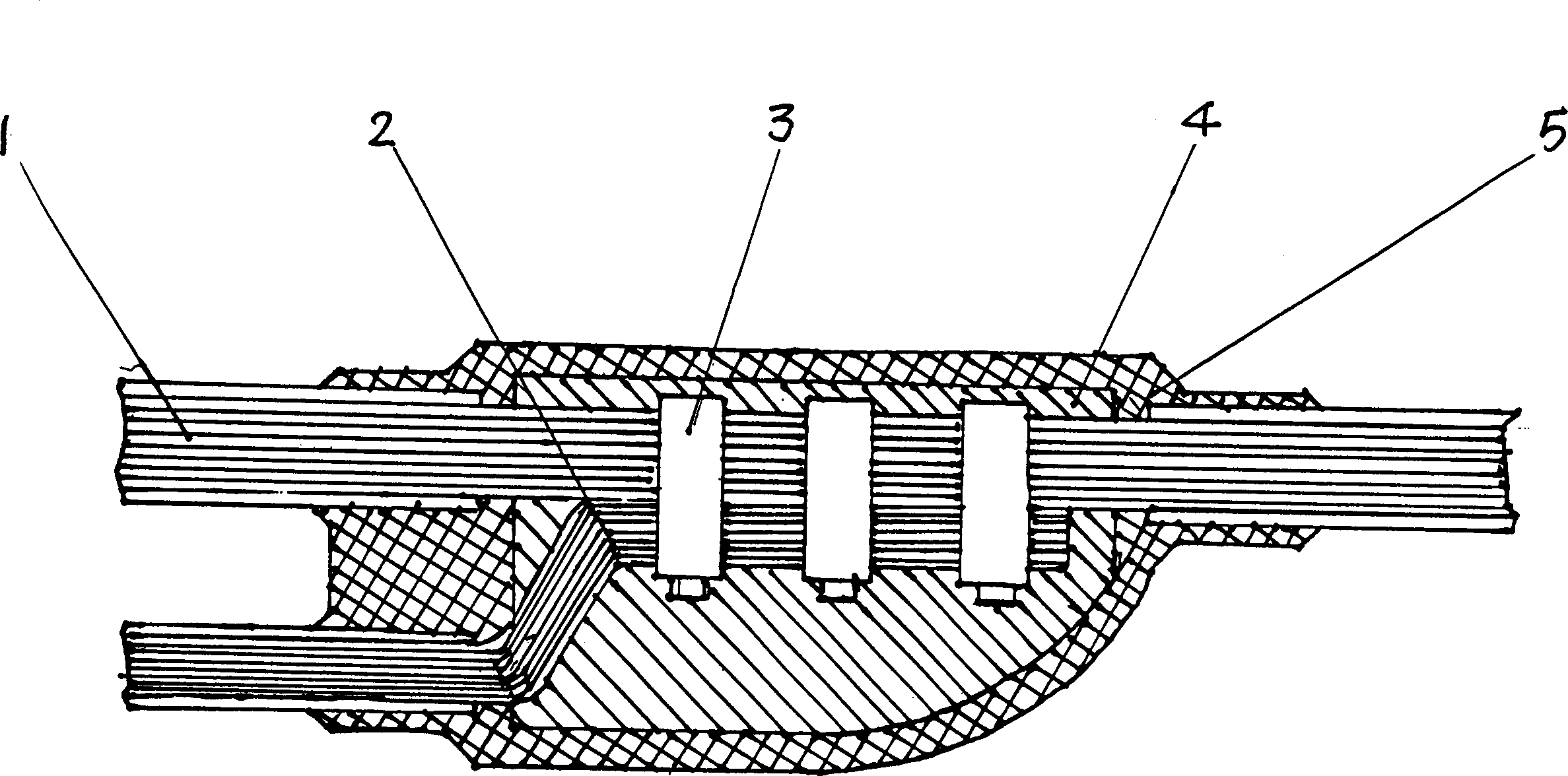

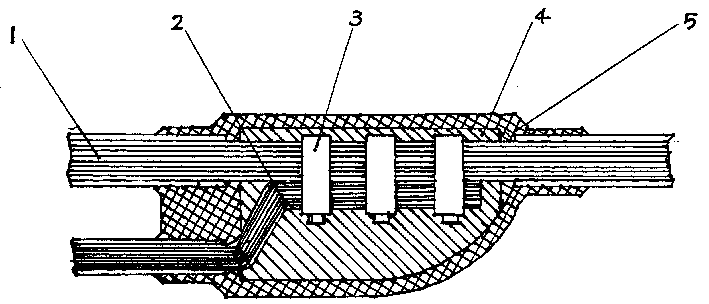

[0012] It includes a main cable 1 and a branch cable 2, the junction of the two is fixed by a splint 3, and there is a cast aluminum protective sheath 4 at the junction of the two, the cast aluminum sheath is cast as one with the two cables and the splint The outside of the protective cover is a rubber and plastic insulation cover 5.

[0013] The manufacture method of the present invention is:

[0014] (1) Strip the joints of the main cable and branch cables;

[0015] (2) Clamp and fix the main cable and branch cable at the joint with a splint;

[0016] (3) Cast aluminum at the joint;

[0017] (4) The outer skin at the joint is injection molded with insulating polyvinyl chloride at one time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com