Method for preparing probe tip of nano tube

A technology of probe tips and nanotubes, which is applied in the field of preparing nanotube probe tips, can solve the problems of uncontrollable growth point position and size, low efficiency, etc., and achieve the effects of convenient operation, simple equipment, and improved resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

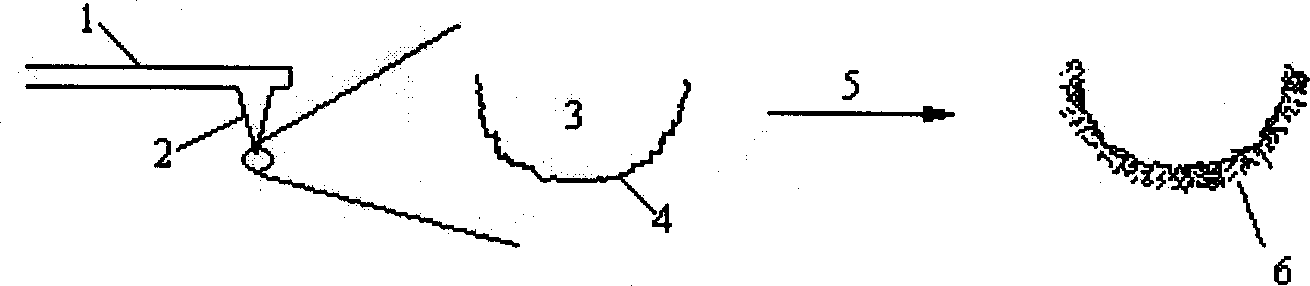

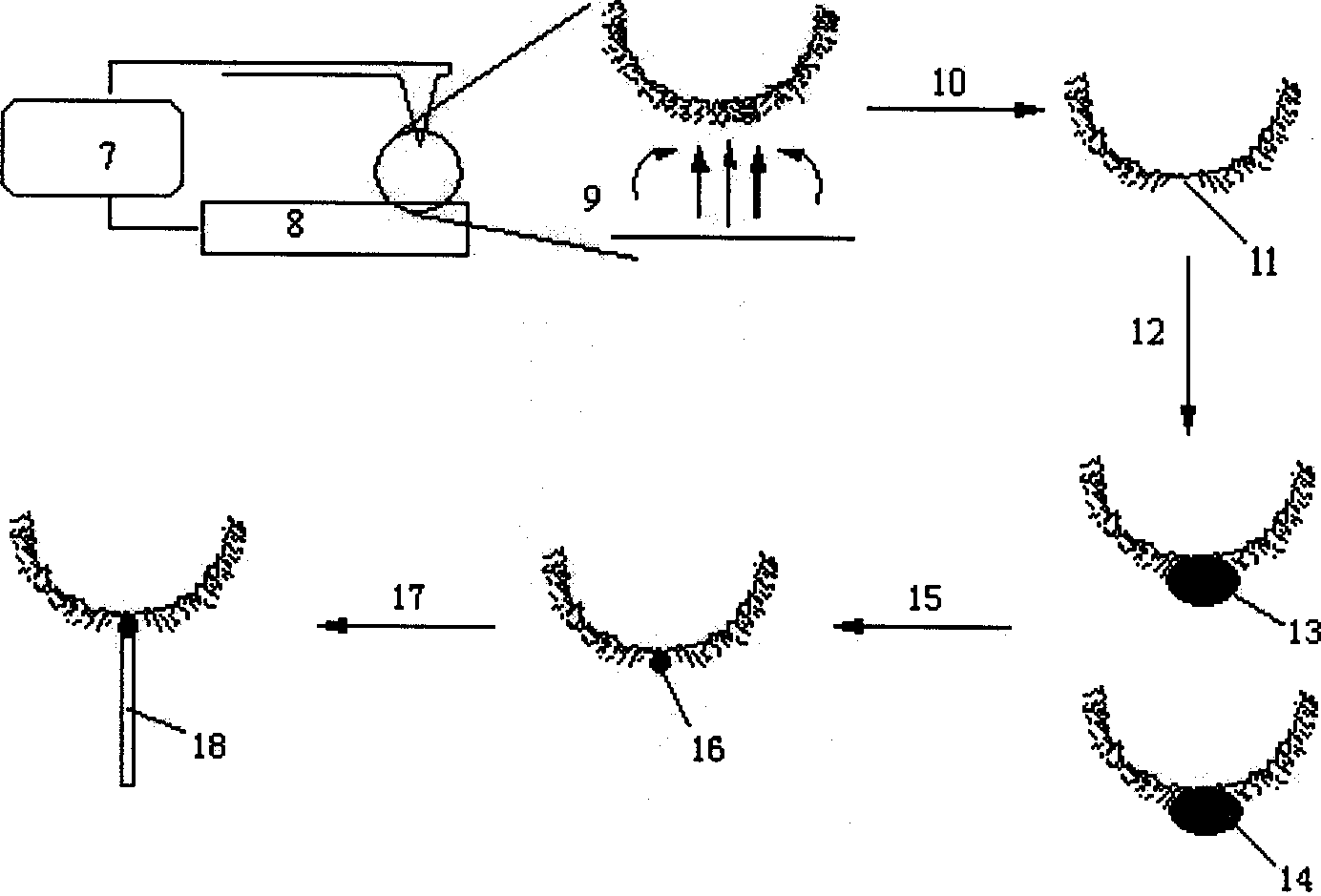

[0024] The method for preparing the nanotube probe tip of the present invention comprises the following steps: (1) modifying the hydrophobic monolayer film on the surface of the probe tip, (2) removing the hydrophobic monolayer film at the tip of the needle tip by a pulse electric field or removing (3) Calculate the size of the activation area by detecting the effect of the needle tip with the electric field on the surface of the standard sample by scanning probe microscope, (4) Adsorb the catalyst droplet in the hydrophilic area at the tip of the needle tip To immobilize the catalyst particles, (5) place the tip loaded with the catalyst nanoparticles in the nanotube reactor to grow nanotubes.

[0025] The probe tip can be a tip made of silicon semiconductor material, or a silicon tip that has been coated with a metal or non-metal film or a compound film.

[0026] The hydrophobic monolayer film on the probe tip can be bonded to the surface of the tip by chemical reaction, or f...

Embodiment

[0034] Example, Hydrophobic treatment of needle tip: Immerse the clean silicon needle tip in 0.1% (volume ratio) octadecyltrichlorosilane benzene solution for 26 hours, take it out, soak it with chloroform and ethanol in turn, and then dry it with nitrogen. Selective activation of silicon tip hydrophobic monolayer film: control the distance between the tip of the hydrophobic film and the gold thin film sample, and apply a pulse voltage, such as 0.4 volts for 100 milliseconds to complete the activation. Fixation of catalyst particles: immerse the activated needle tip in a 0.5 molar ferric nitrate solution, take it out and dry it in a drying oven at 110°C for 2 hours. Growth of carbon nanotubes: put the needle tip immobilized with the catalyst into a furnace, feed 0.5 L / min ethylene gas, and grow at 750 degrees Celsius for 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com