Electric/mechanic operating mechanism of hydraulic turbine blades

An operating mechanism and water turbine technology, applied in the direction of machines/engines, electromechanical devices, hydroelectric power generation, etc., can solve the problems of oil pump wear, complex structure, difficult sealing, etc., achieve reduced wheel-hub ratio, significant economic benefits, increase flow and The effect of effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

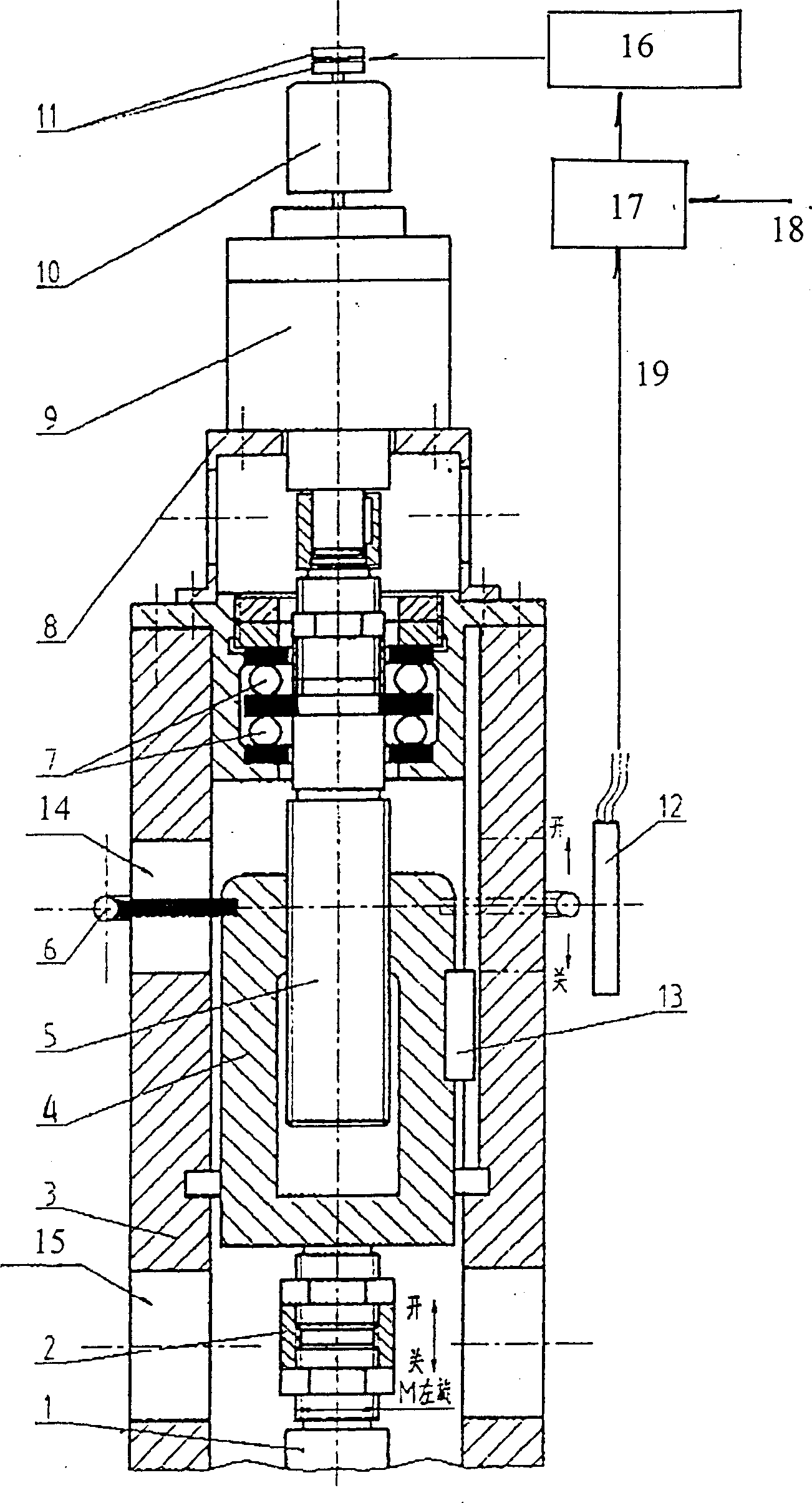

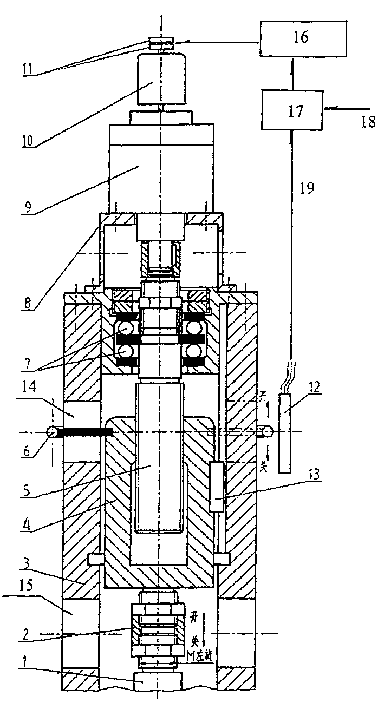

[0017] as attached figure 1 Summary of the invention: the present invention adopts a kind of electric / mechanical operating mechanism to replace the oil cylinder system to adjust the opening (rotation angle) of the water turbine blade. The devices are all installed on the unit main shaft 3 and rotate together with the main shaft. Its servo system adopts DC servo motor 10 and harmonic deceleration device 9 and its driving power supply 16 and control circuit 17, and the servo motor control circuit 17 and power supply 16 are then connected with the servo motor through slip ring 11. The transmission mechanism adopts the screw nut sleeve structure, which is placed in the main shaft of the unit. The output shaft of the DC servo motor and the harmonic reduction device drives the trapezoidal screw 5 forward and reverse. Connect the operating shaft 1, and the operating shaft is directly connected to the paddle operating mechanism in the runner body of the water turbine.

[0018] The D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com