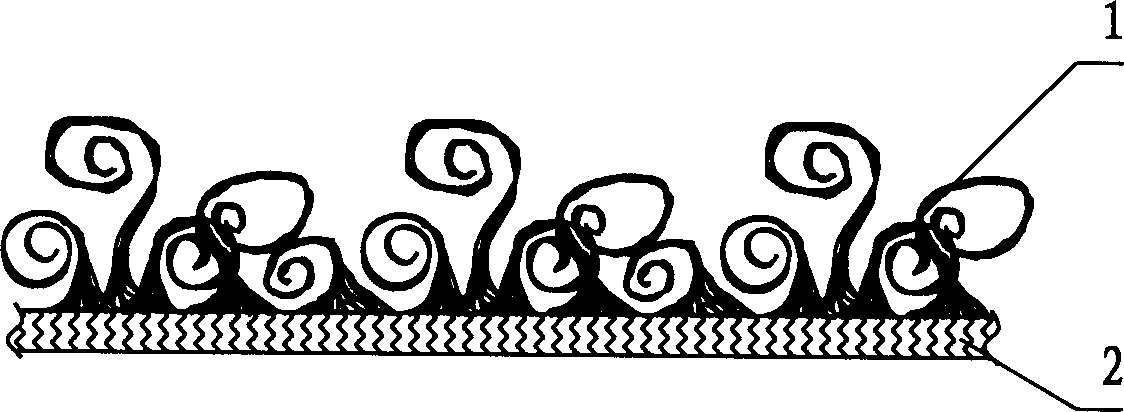

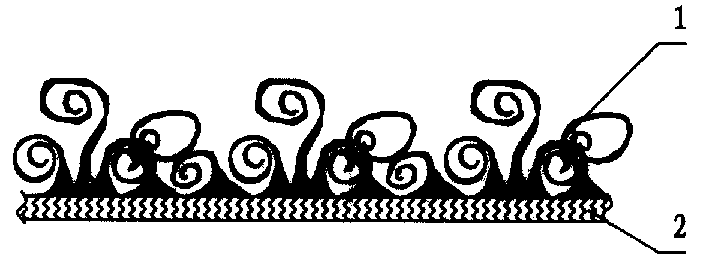

Wool-acrylic fiber cospinning pearl lint and manufacture process thereof

A pearl and wool nitrile technology, applied in the field of textile products, can solve the problems of single color on the surface of the cloth, increase equipment and processes, increase production costs, etc., and achieve the effect of strong three-dimensional effect, low manufacturing cost and strong warmth retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 The veil is made of 24S / 2 wool and acrylic blended yarn, the bottom yarn is 200D polyester elastic yarn, and the bottom yarn and the veil are woven with a knitted loop pile loom to have a wool height of 10-18m / m and a grammage of 300-300m / m. 800g / m 2 After the semi-finished gray cloth is processed, the semi-finished gray cloth is processed according to the existing conventional processes (such as sizing, brushing, ironing, etc.), and then humidified. The humidification temperature is 75-80°C; the humidification process can be washed with water or padding. Humidify the gray cloth, then carry out centrifugal dehydration, or use water spray method for humidification, and finally make the moisture content of the semi-finished gray cloth reach 60%. 95-100% for 25-30 minutes; finally use a stenter setting machine for setting and drying, the temperature is controlled at 125-130°C, and the drying rate is 5-5.2m / min, the product of the present invention can be obtained...

Embodiment 2

[0020] Example 2 The face yarn is made of 48S / 2 wool and acrylic blended yarn, the bottom yarn is 100D polyester elastic yarn, the humidification temperature is 10-15°C, and the moisture content is 10%; the crimp forming temperature is 80-85°C, and the humidity is 80-85%. , the time is 5-7min; the setting drying temperature is 80-85°C, the drying rate is 5-5.5m / min, and the rest are the same as in Example 1.

Embodiment 3

[0021] Example 3 The face yarn is 36S / 2 wool-acrylonitrile blended yarn, the bottom yarn is 200D polyester filament, the humidification temperature is 45-50°C, and the moisture content is 30%; the crimp forming temperature is 100-105°C, and the humidity is 95-100% , the time is 25~30min; the setting drying temperature is 125~130°C, the drying rate is 29~30m / min, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com