Great-power laser diode array pumping cavity for pumping solid laser

A technology of laser diodes and solid-state lasers, applied in the field of pumping cavities, can solve the problems of unfavorable engineering and mass production, many components, and rising costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

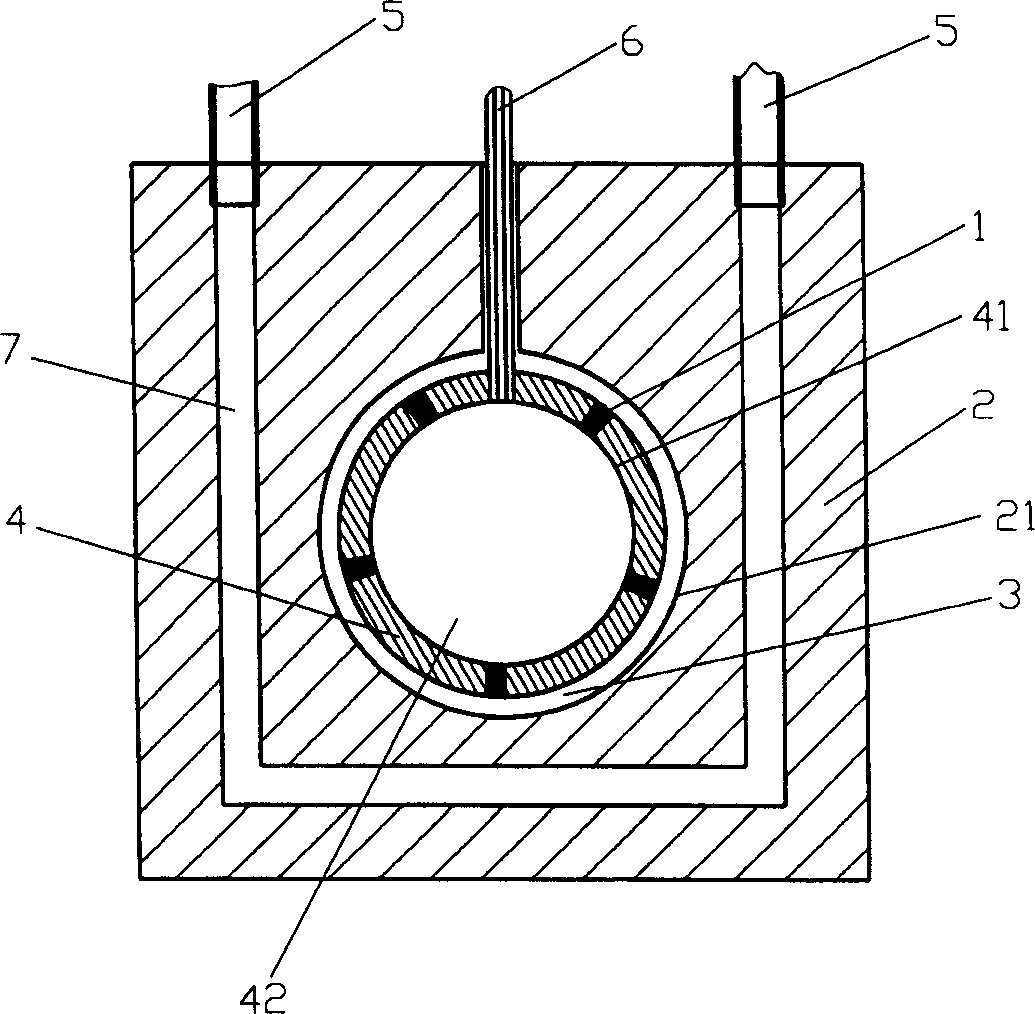

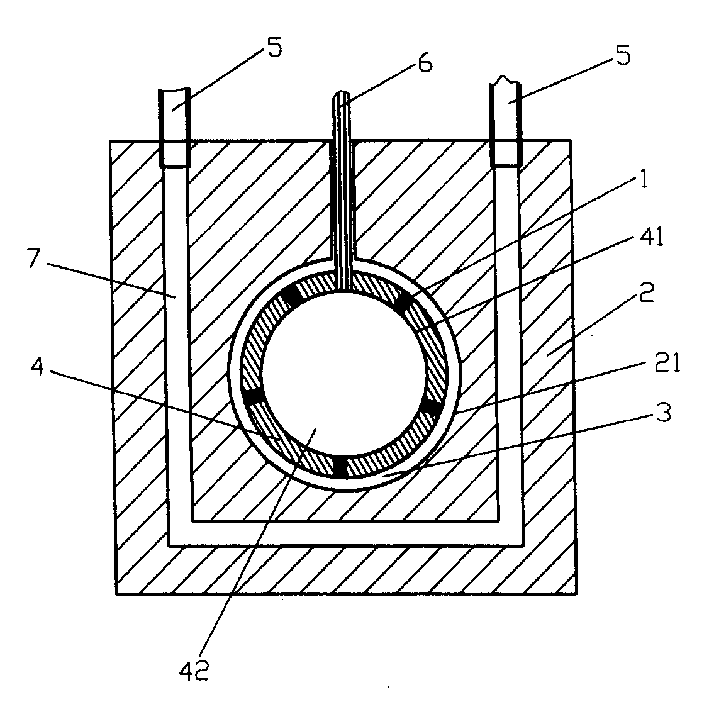

[0012] figure 1 The laser diode array pump cavity shown includes: laser diode array bar 1, heat sink 2, insulating ring 3, arc-shaped transition electrode 4, water inlet and outlet conduits 5, positive and negative electrodes 6, and cooling water channel 7.

[0013] These include:

[0014] A heat sink 2, the heat sink is a metal with high thermal conductivity and easy processing, the heat sink 2 is a rectangular body, and a through hole 21 is opened in the middle of the heat sink 2;

[0015] An insulating ring 3 is placed in the through hole 21 of the heat sink 2. The outer diameter of the insulating ring 3 is the same as the inner diameter of the through hole 21. The insulating ring 3 is an insulating material with high thermal conductivity. electroplating metallization;

[0016] A plurality of laser diode array strips 1 and a plurality of arc-shaped electrodes 4 form a circle and are installed on the inner surface of the insulating ring 3, and the arc-shaped electrodes 4 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com