Independent flow-thru capacitor

A flow-through capacitor technology, applied in capacitors, fixed capacitors, through-hole capacitors, etc., can solve the problems of easy leakage, lack of industrial convenience, etc., and achieve the effect of easy output, automatic output, and small dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Using the roller coating method, the self-made hydrated iron oxide uniform slurry is coated on the aluminum foil with a size of about 150mm×490mm×0.1mm to form FTC. The slurry is based on the following formula:

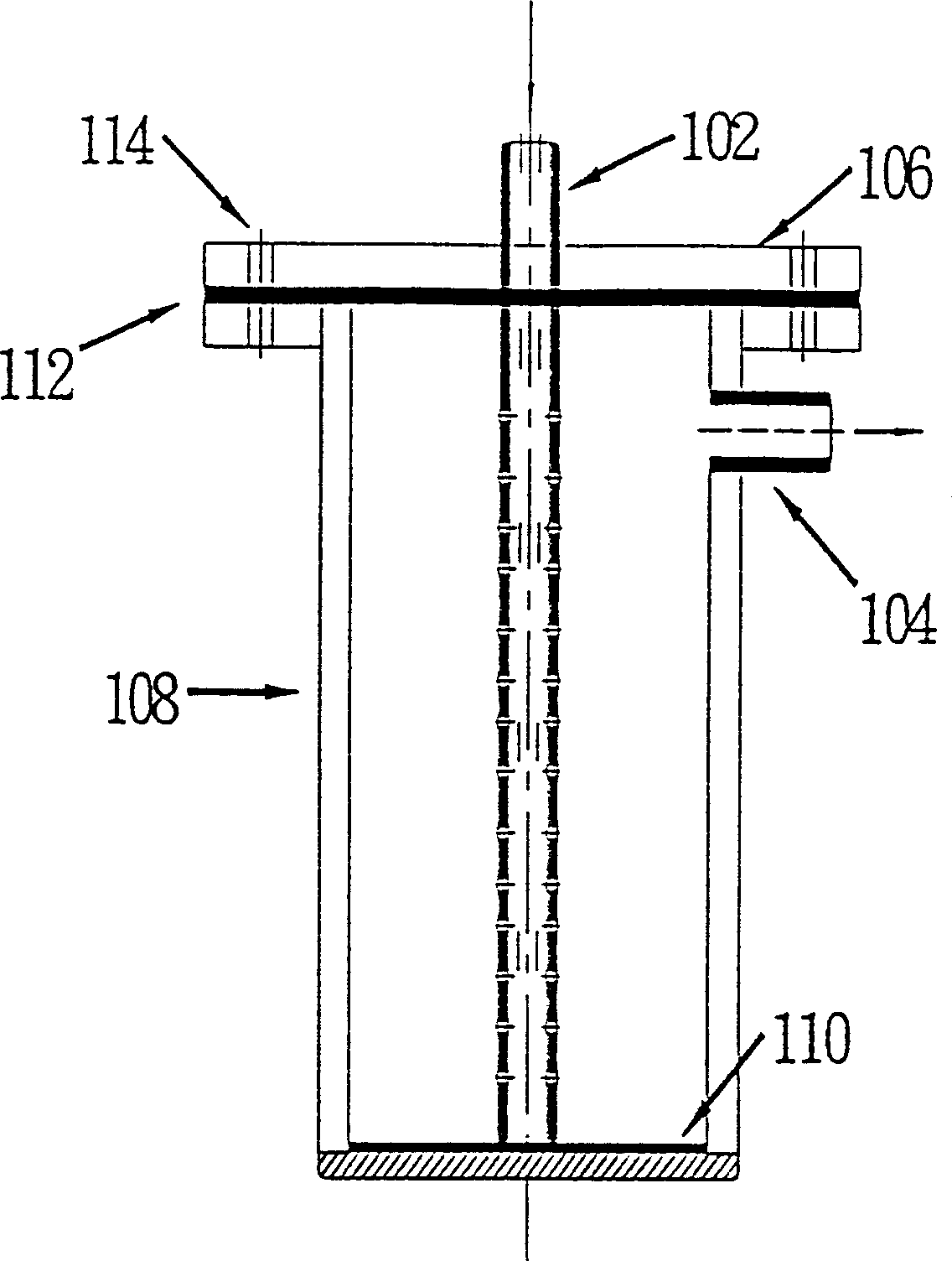

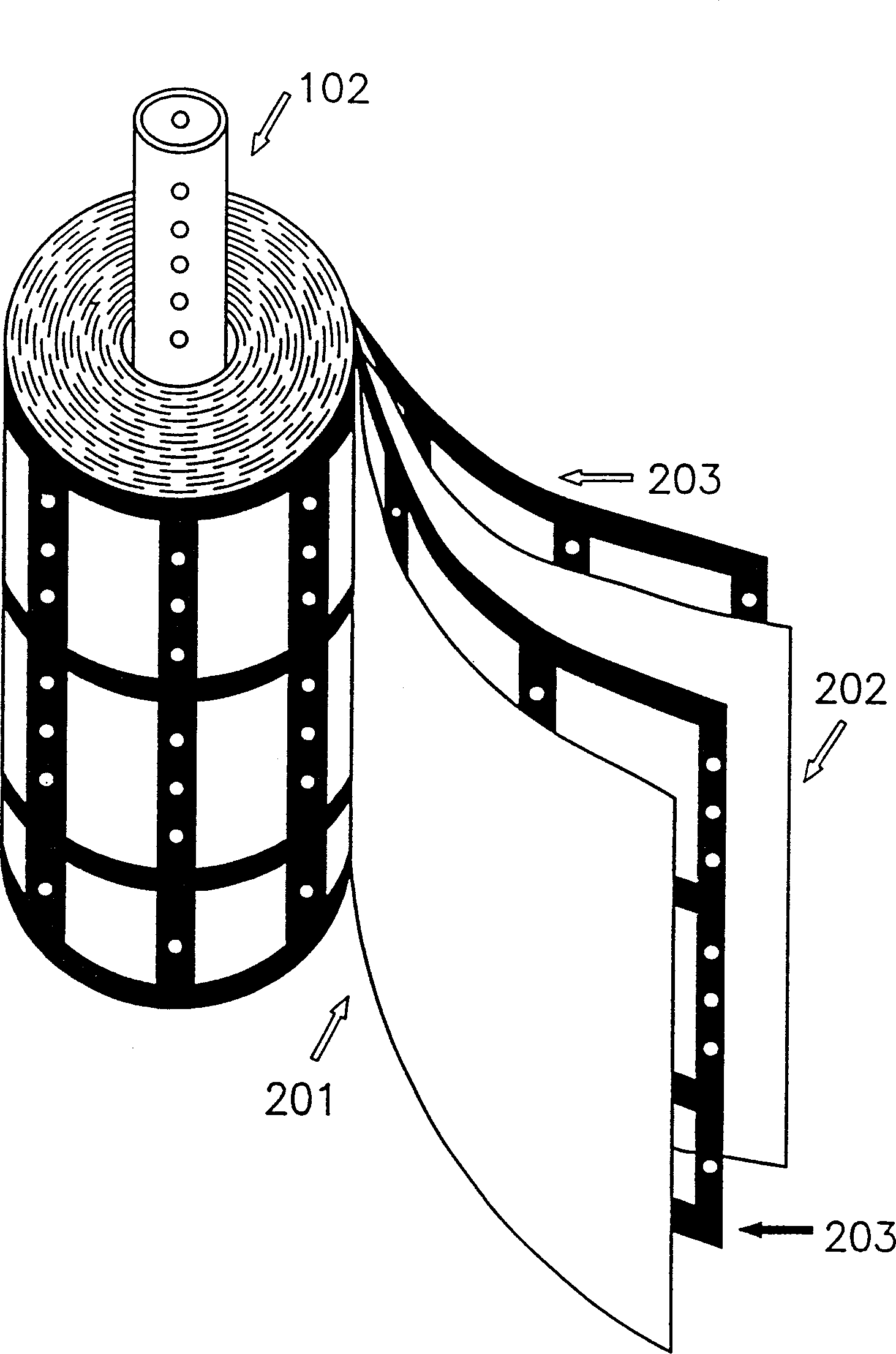

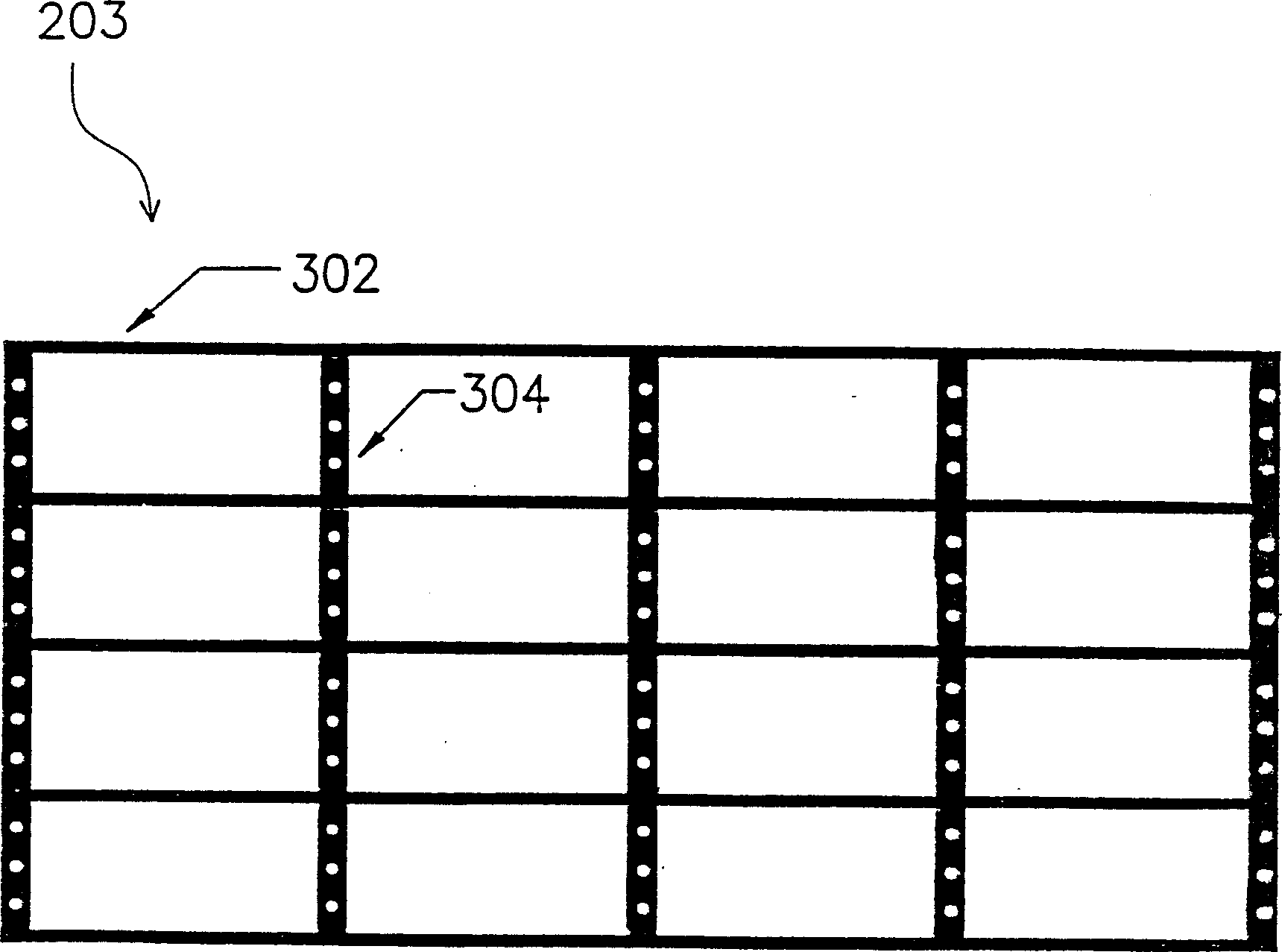

[0033] 1g Fe 3 o 4 And 0.03g PVDF (polyethylene fluoride) and 1.5ml NMP (N-methyl-2-

[0034] After irradiating with IR light or other heating devices, the solvent NMP is evaporated, and the electrode and the separator are rolled into such a figure 2 FTC reel shown. The tabs of the base foils of the anode and cathode serve as electrical leads and are connected to a DC power source. Insert the liquid inlet pipe 102 into the center of the reel, and then put the FTC into the plastic container body 108, wherein the inner diameter of the container body 108 is 60mm and the height is 150mm. Then, use bolts and nuts to fix the top cover 106 on the container 108, thereby sealing the container 108, and at the same time extend the two lug wires to the outside of the...

Embodiment 2

[0041] Rinse the spent FTC of Example 1 with deionized water until the effluent shows low conductivity (read the μS value displayed digitally). The following tests were performed with the regenerated FTC.

[0042] Liquid: CuSO 4 Aqueous solution with a conductivity of 1420μS / cm

[0043] Voltage: 1.0DC volts

[0044] Liquid flow rate: 50ml / min

[0045] Number of Cassettes: 2 The conductivity of the first collected 50ml effluent was measured to be 724 μS / cm, indicating that 49% of the ions were removed once the fluid passed through the FTC at very low voltage.

Embodiment 3

[0047] FTC for seawater desalination was prepared using a regeneration method similar to that of Example 2. Seawater from the Pacific Ocean is obtained from somewhere on the west coast of Taiwan. In order to meet the measurement range of the conductivity meter used in the present invention, the sample was diluted 50 times with deionized water. The TDS (Total Dissolved Solids) of the samples used was estimated at 20,000 ppm. Without any pretreatment, the desalination test of diluted seawater was carried out under the following conditions.

[0048] Liquid: Diluted seawater with a conductivity of 793μS / cm

[0049] Voltage: 1.0DC volts

[0050] Liquid flow rate: 50ml / min

[0051] Number of cassettes: 2

[0052] The conductivity of the first collected 50ml effluent was measured at 619 μS / cm, a total of 21% of the ions were removed. This example has the same number of cassettes as Example 1, but the deionization capability of this example is relatively poor. This may be becau...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic flux density | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com