Normal temperature extruding method of window curtain blade

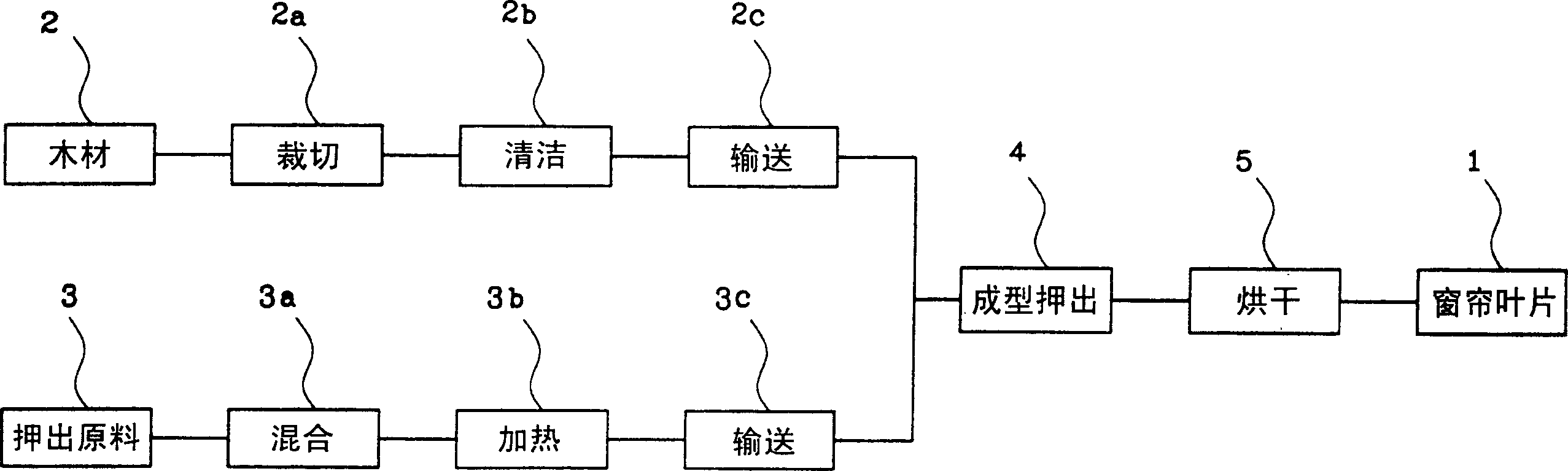

A blade and curtain technology, which is applied in the field of normal temperature extrusion of curtain blades, can solve the problems of wood moisture loss, poor quality and appearance of finished products, and increased loss rate of machinery and equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

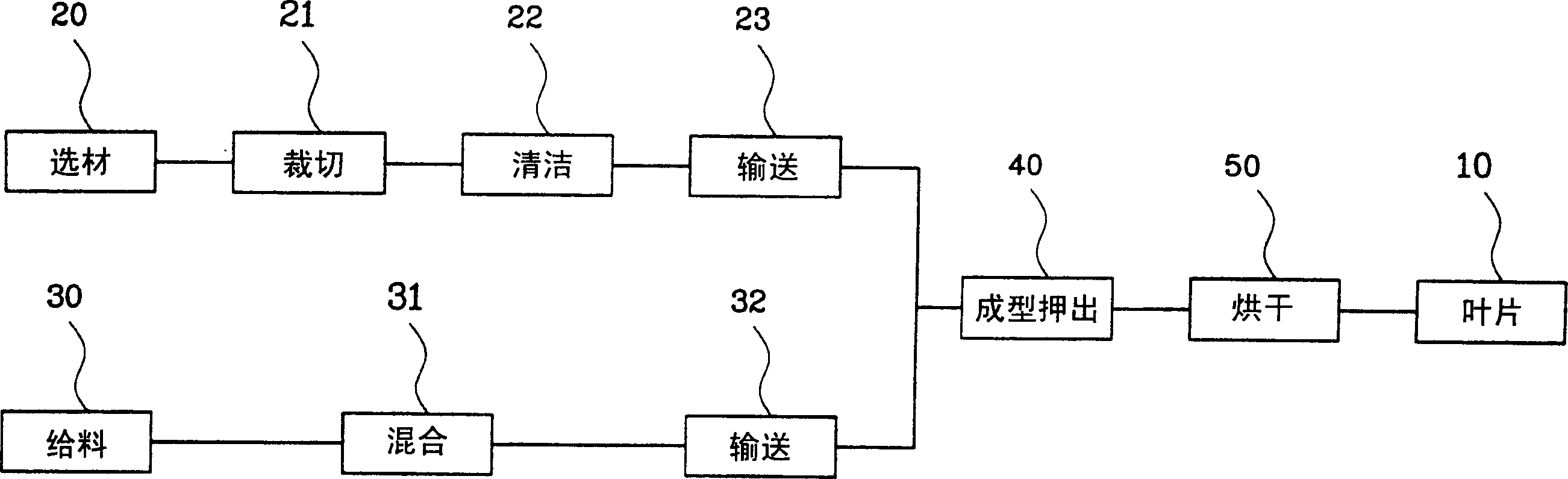

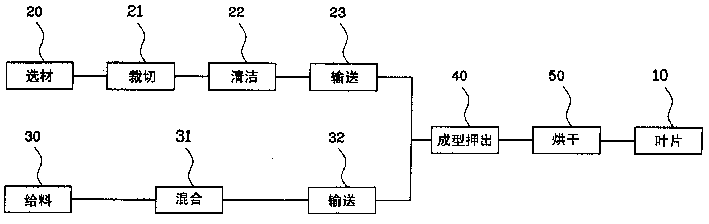

[0013] see figure 2 , is a normal temperature extrusion method for a curtain blade 10 provided by a preferred embodiment of the present invention, and its manufacturing steps are as follows:

[0014] (1) Material selection operation 20:

[0015] (a) cutting 21: cutting the selected wood into plates of predetermined shape, size and thickness;

[0016] (b) Cleaning 22: cleaning, decontaminating and repairing the cut plates;

[0017] (c) Conveying 23: Conveying the cut and cleaned plates through a conveying propeller into a molding die;

[0018] (2) Extruding raw materials to make operation 30:

[0019] (a) Feed material 31: Put an extruded main raw material into a mixer and stir evenly to form a mixed solution; the main raw material is 0.5-1.0 kg of methyl cellulose (Methyl Cellulose, MC, seaweed powder), 8.5 kg of water -1.6 kg, calcium carbonate (stone powder) 16-30 kg, white glue 2.5-5 kg and Yijiaojing 2.5-5 kg, the weight ratio is about 0.2:3.3:6:1:1;

[0020] (b) c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com