Projection television projecting subassembly

A technology for projection components and projection TVs, used in TVs, color TV parts, TV system parts, etc., can solve the problems of uneven sealing surface and reduced sealing reliability, and achieve stable corrosion resistance and reliability. , The effect of improving sealing reliability and superior surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

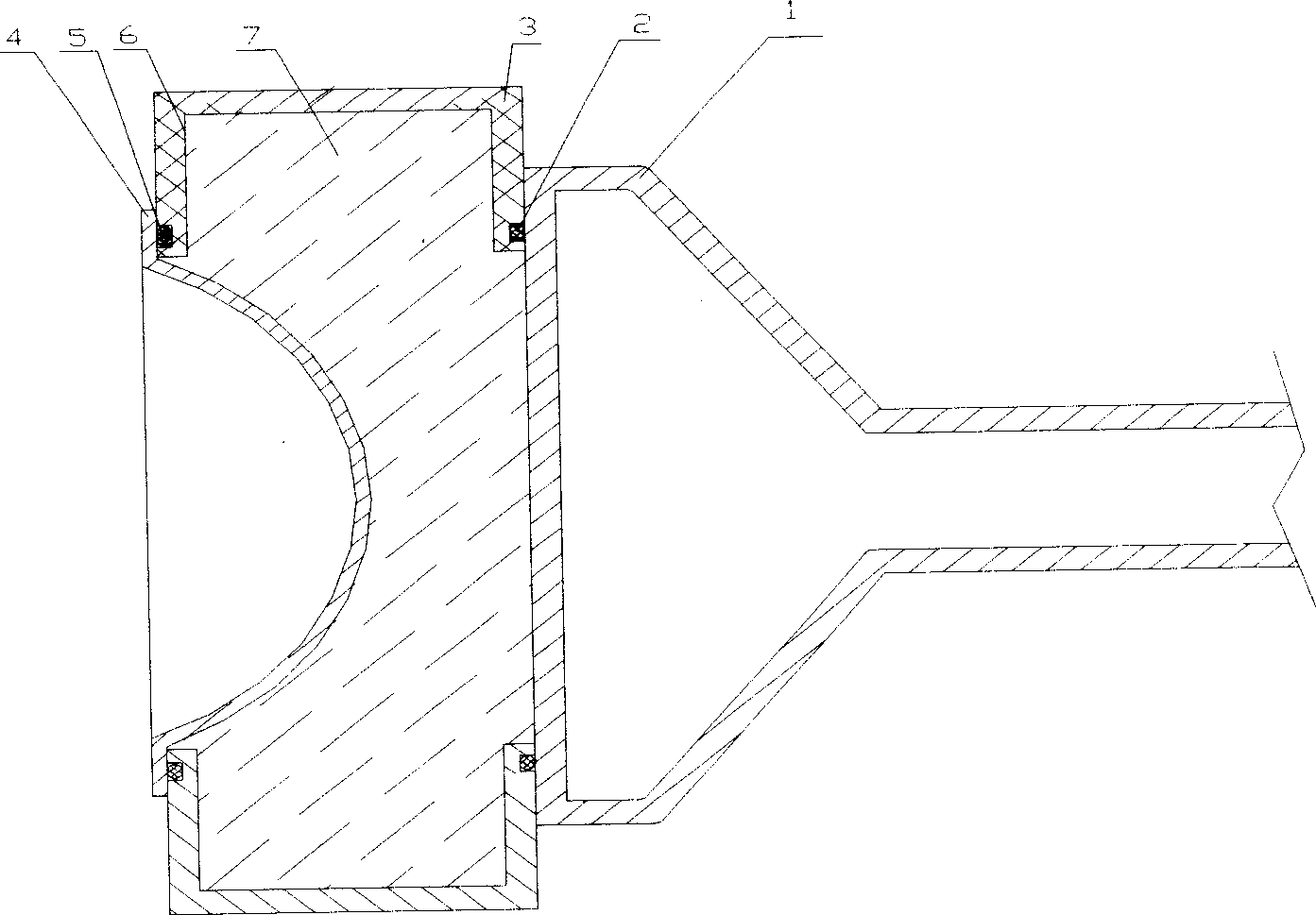

[0014] figure 1 is a sectional view of the cooling chamber part of the projection assembly in the prior art. The projection tube 1 is fixed on the radiator 3 through the seal 2, the C bowl lens 4 is fixed on the radiator 4 through the seal 5, and the cooling cavity formed by the C bowl lens 4, the projection tube 1, and the radiator 3 is filled with cooling water. Liquid 7.

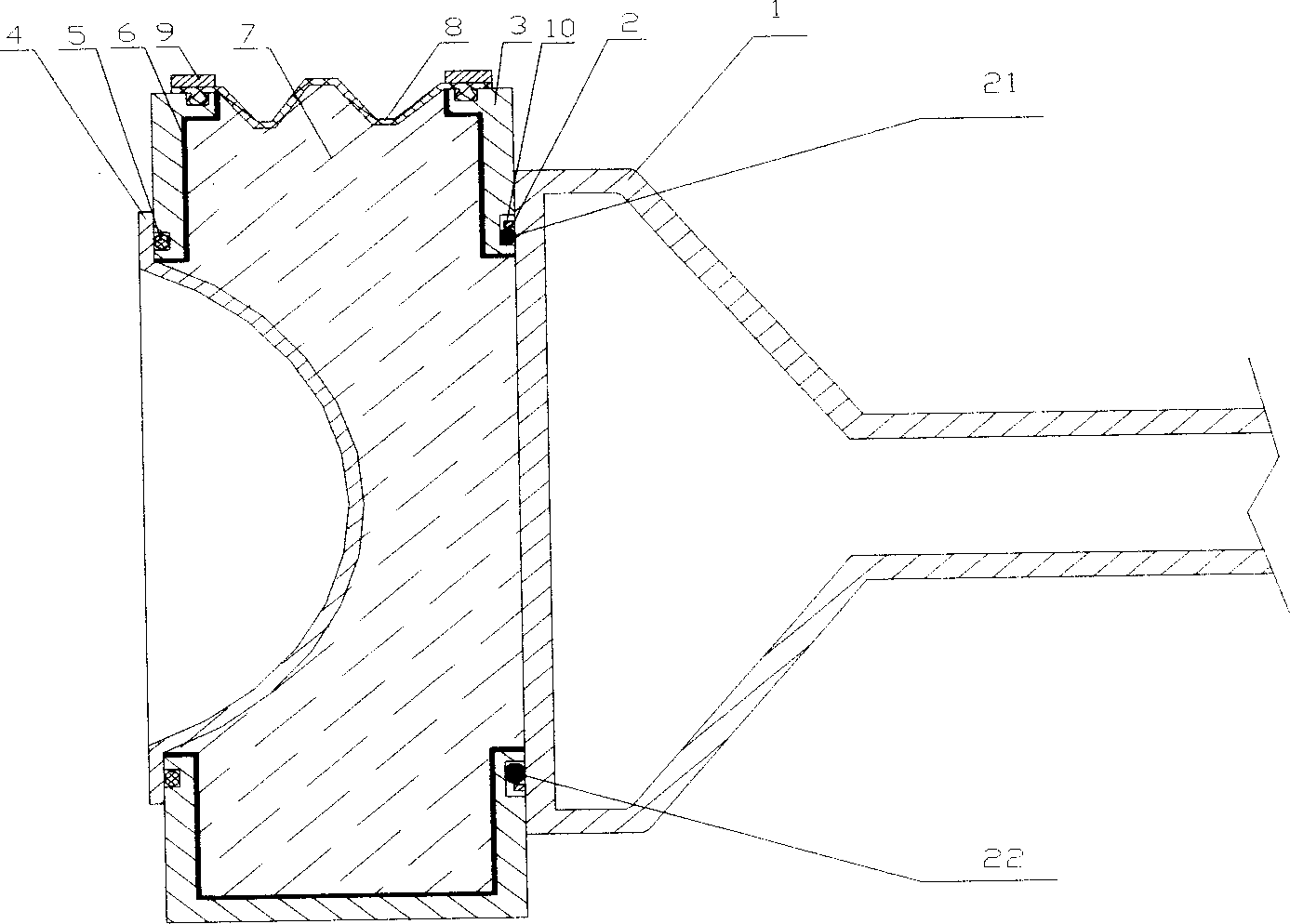

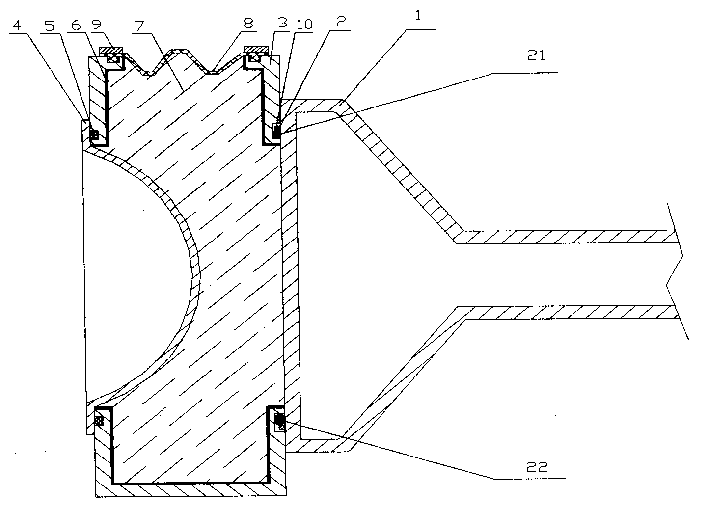

[0015] figure 2 It is a sectional view of the cooling cavity part of the projection assembly of the present invention, including a projection tube 1, a C bowl lens 4 arranged in front of the projection tube front, a radiator 3 arranged between the projection tube 1 and the C bowl lens 4, a radiator 3 and The first sealing member 2 between the projection tube fronts, the second sealing member 5 arranged between the above-mentioned radiator 3 and the C bowl lens 4, the cooling liquid 7 filled between the projection tube 1, the C bowl lens 4 and the radiator 3, A ceramic-like surface 6 formed by plasma s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com