Sealing method for split type magnetic liquid sealing device

A magnetic liquid and sealing device technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve problems such as uneven application and affecting sealing performance, and achieve the effect of improving sealing reliability and ensuring sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

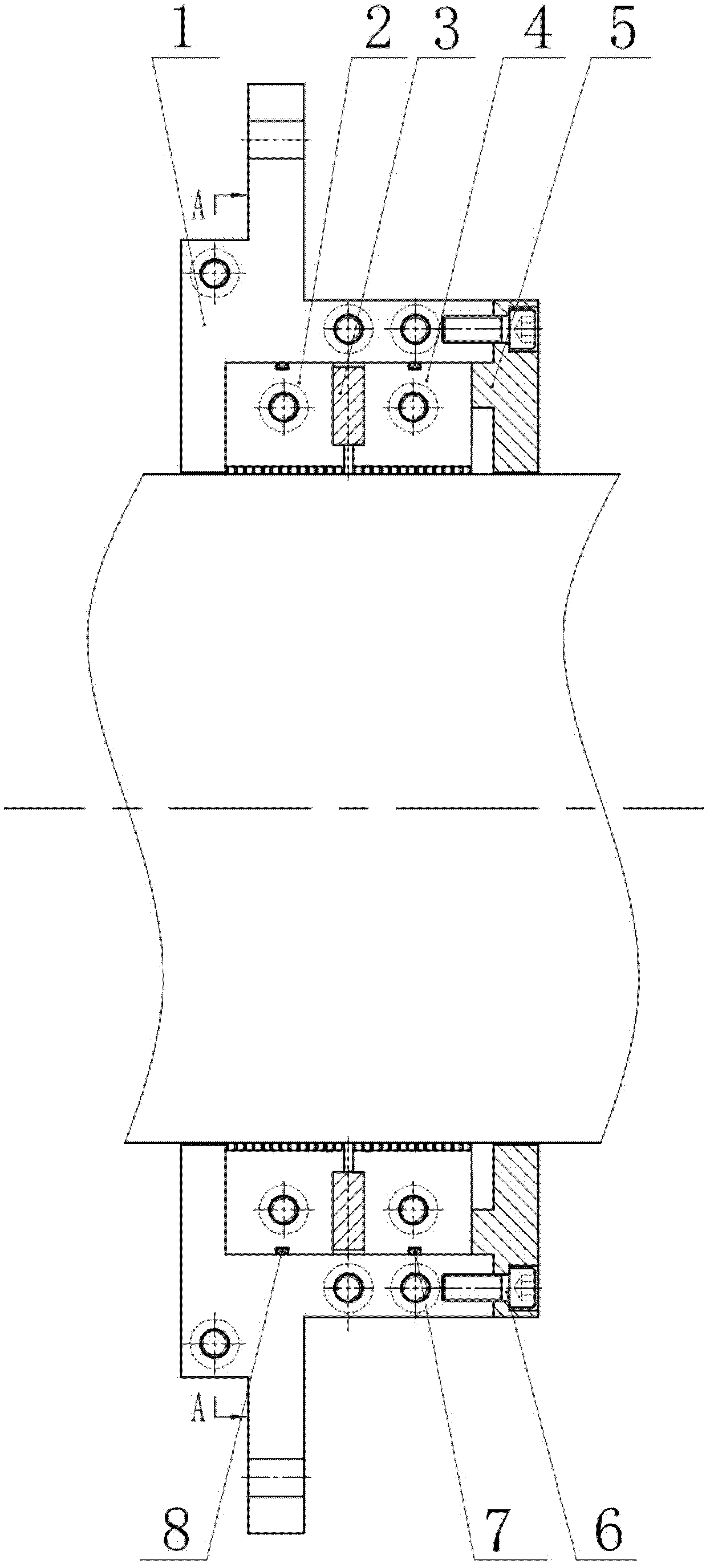

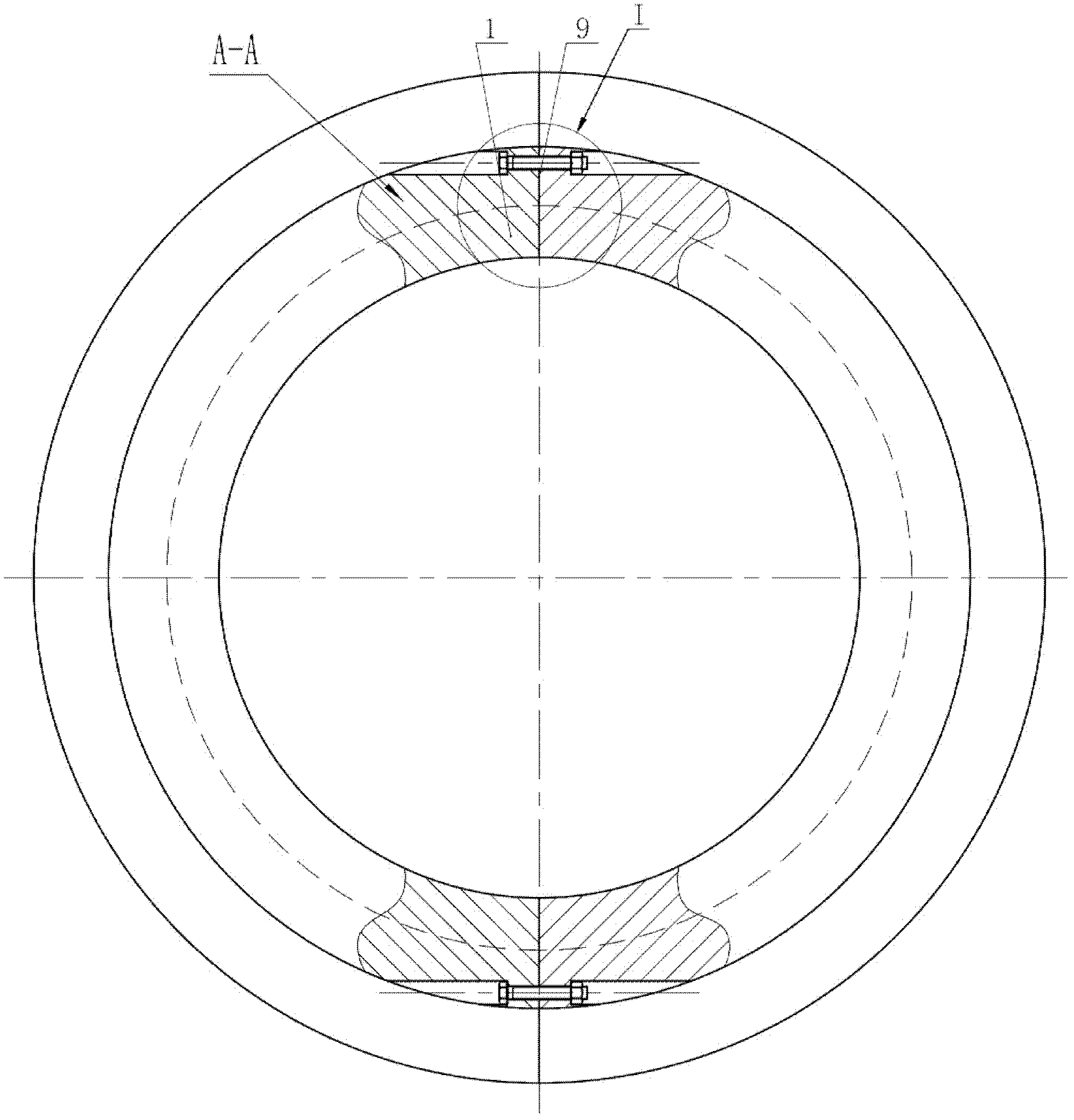

[0021] A sealing method for a split-valve magnetic liquid sealing device, the sealing method comprising:

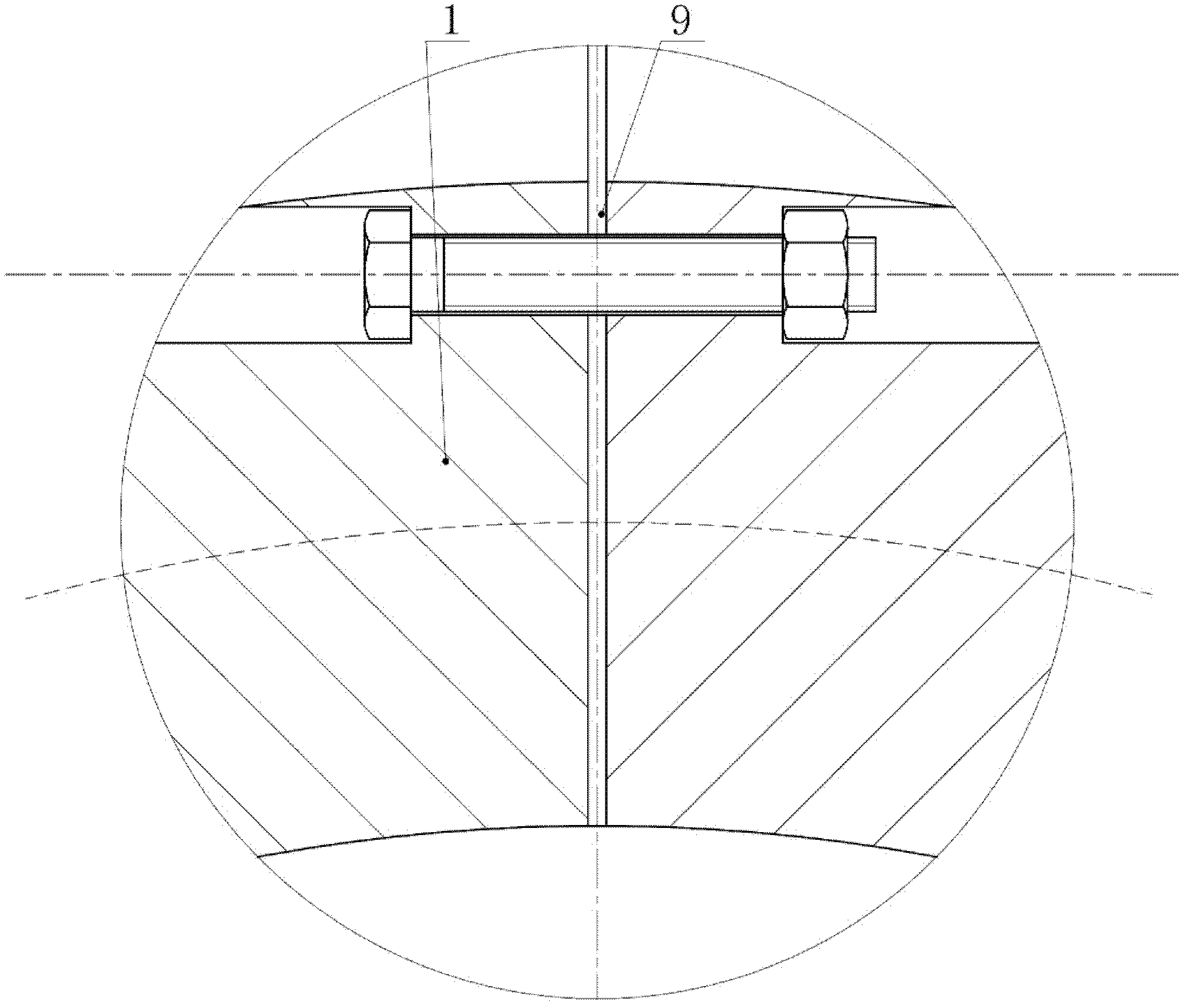

[0022] Buckle the two halves of the shell on the shaft to be sealed, connect the two halves of the shell with bolts and nuts, and apply sealant on the joint surface to form the shell 1;

[0023] Fasten the two halves of the pole shoe on the shaft to be sealed, connect the two halves of the pole shoe with bolts and nuts, and apply sealant on the joint surface to form the left pole shoe 2;

[0024] Fasten the other two halves of the pole shoe on the shaft to be sealed, connect the two halves of the pole shoe with bolts and nuts, and apply sealant on the joint surface to form the right pole shoe 4;

[0025] Insert the first rubber sealing ring 8 into the concave groove on the outer surface of the left pole piece 2, and insert the second rubber sealing ring 7 into the concave groove on the outer surface of the right pole piece 4;

[0026] The left pole shoe 2 with the rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com