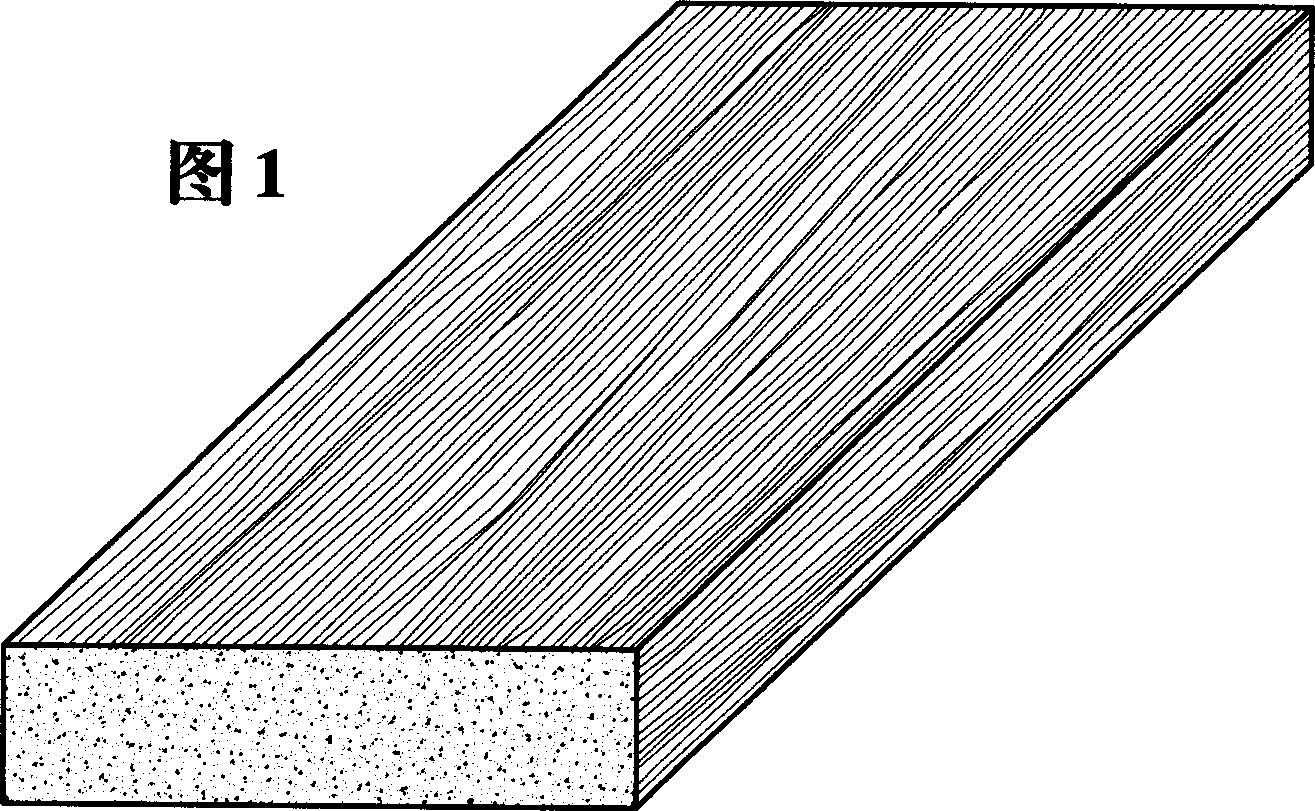

Improved type fine carpentry wood core plate and making method

A blockboard and core board technology, which is applied to wood processing equipment, flat products, manufacturing tools, etc., can solve the problems of low production efficiency, large dry shrinkage rate, and low utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] (1) Raw material preparation

[0015] Peel the freshly cut or undried small-diameter wood, thinned wood, and branch wood. If the raw material is too dry, it needs to undergo pretreatment such as water immersion or steaming to adjust its moisture content to ≥30%;

[0016] (2) Rolling combing and longitudinal separation

[0017] Put the above-mentioned wood section into a rolling roller for proper rolling, so that it is split and preliminarily separated into larger pieces and a network structure that adheres to each other but does not separate. The preliminarily separated net-like structure is then combed with a combing device. The teeth of the combing knife (referred to as comb teeth, the same below) are combed along the grain (or inverted), and the direction of movement of the comb teeth is basically the same as that of the wood fiber. Consistent, use comb teeth to comb the mesh body to force the adhesion part to separate, and at the same time to subdivide the thicker piece...

Embodiment 2

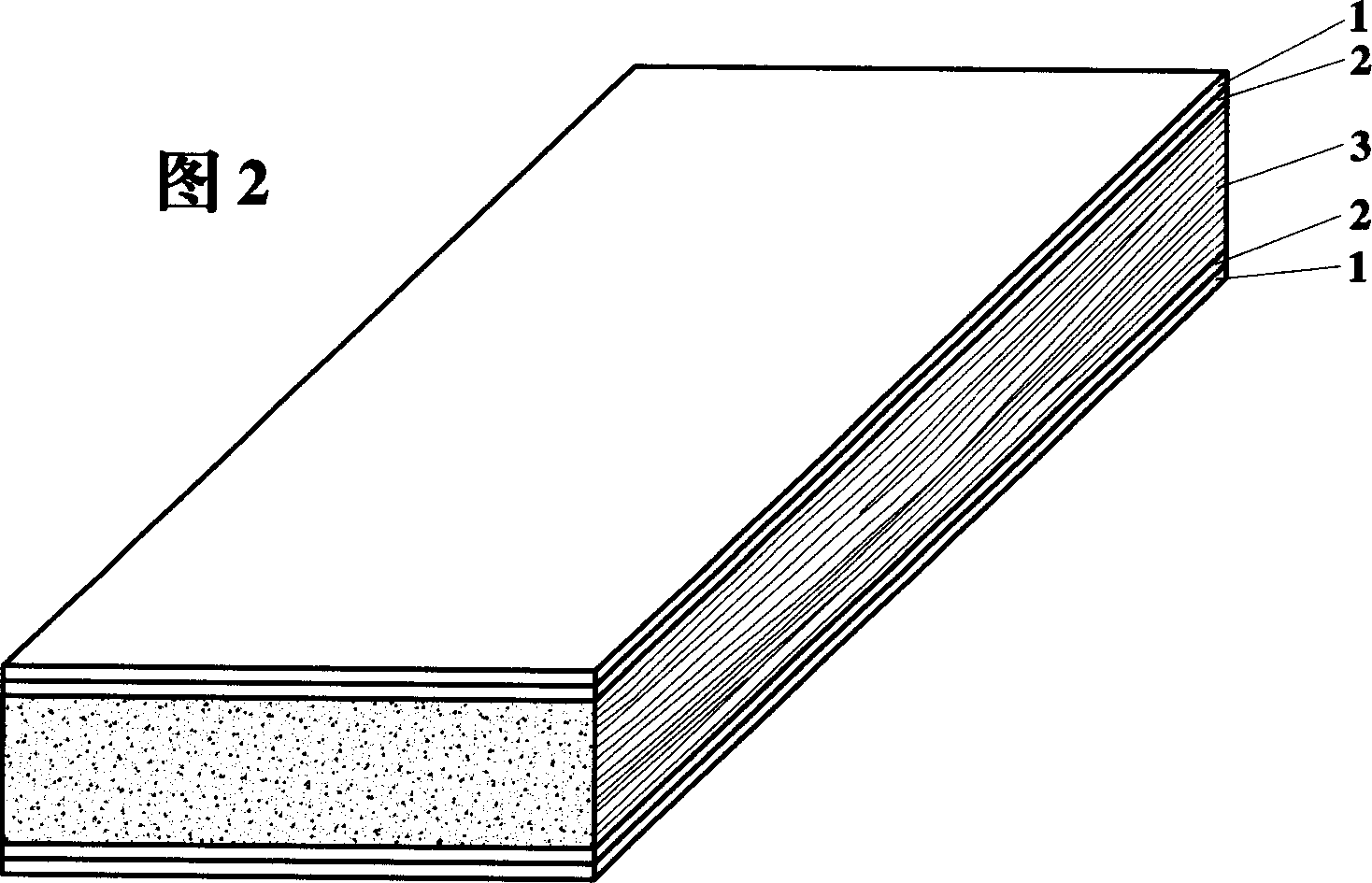

[0038] The new blockboard core board produced by the method described in Example 1 is used as the core layer (3), and ordinary veneers are used as the watch board (1) and the short core board (2). After that, a new type of blockboard can be produced.

[0039] Compared with the ordinary blockboard core board production process, the invention has the advantages of high production efficiency, low energy consumption, high wood utilization rate, low production cost, good quality, and greater social and economic benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com