Plasma etching gas

A technology for etching gas and plasma, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to solve problems such as excessive consumption of photoresist masks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

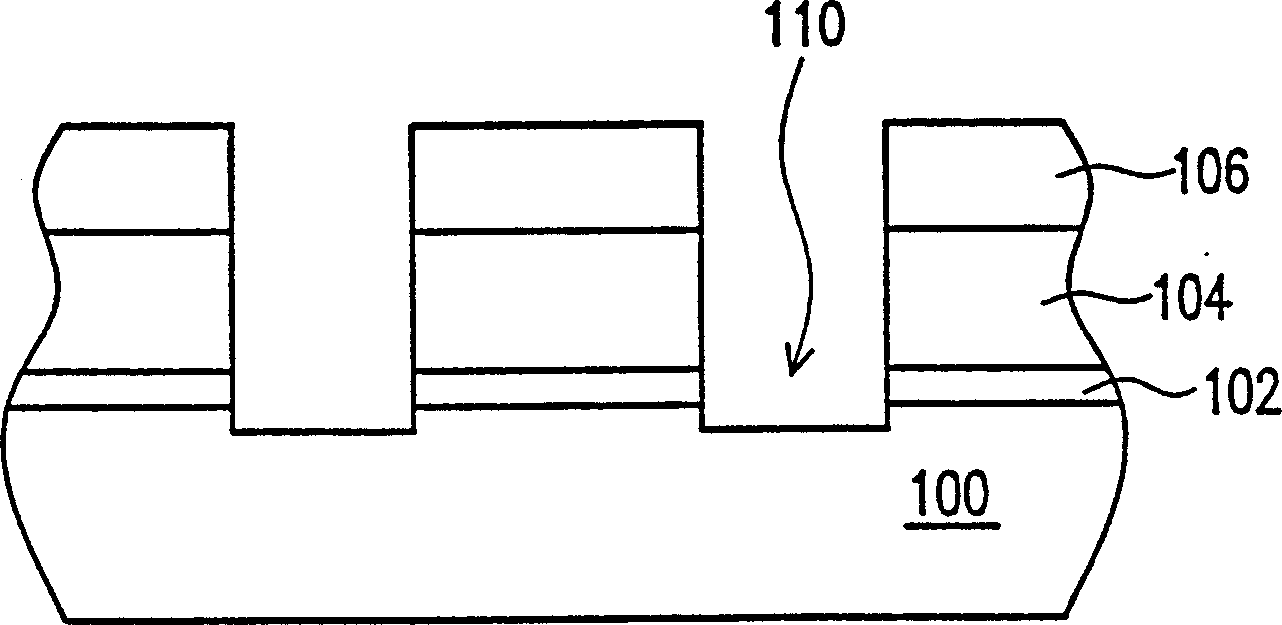

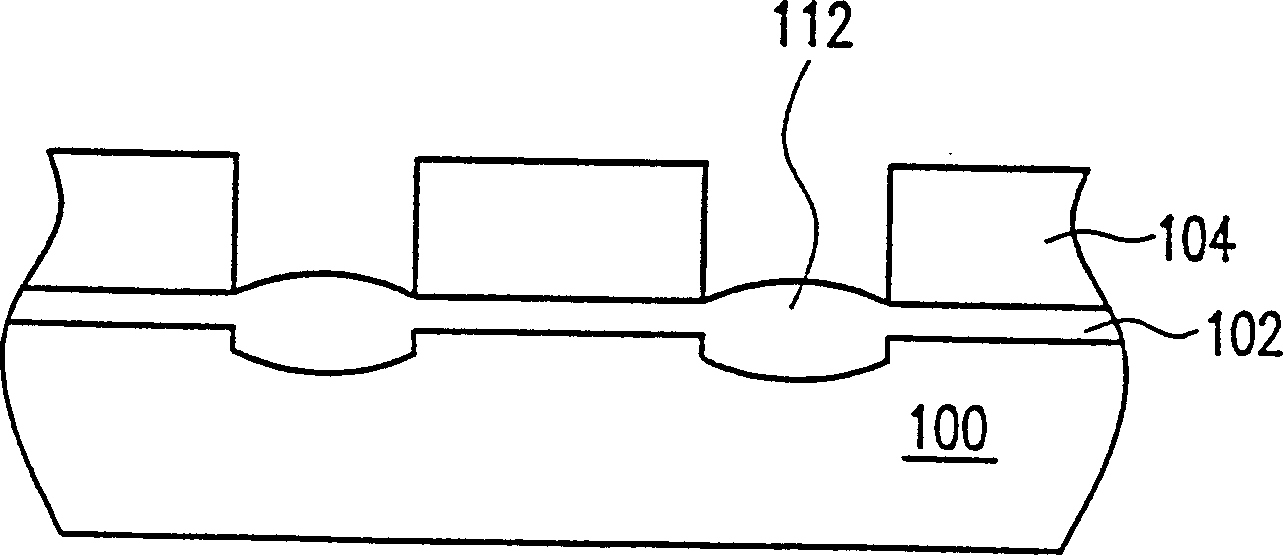

[0015] The invention provides a plasma etching gas for etching a silicon layer. Nitrogen is added to the known plasma etching gas for etching silicon oxide. The nitrogen gas makes the polymer structure deposited on the surface of the silicon layer loose and thin, so that the plasma used for etching can effectively pass through the polymer to etch the silicon layer, so that the etching uniformity of the silicon layer is increased, and at the same time it will not Excessive loss of the photoresist mask affects the etch CD. Wherein, the flow rate of adding nitrogen is 1 sccm to 50 sccm.

[0016] In the etching machine for etching silicon oxide, the etching gas used for etching the silicon oxide layer and the silicon layer includes halothane gas and argon gas. Halothane gases include fully substituted halothane gases (C x f y ) and partially substituted halothane gas (C x h y f z ). Fully substituted halothane gas (C x f y ), such as carbon tetrafluoride (CF 4 ), carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com