Process method and system for synthesizing methanel using by-product coal-gas during metallurgical process

A technology for by-product gas and methanol synthesis, applied in chemical instruments and methods, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve the problem of high cost, reduce product energy consumption and production cost, reduce emissions, and invest less Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

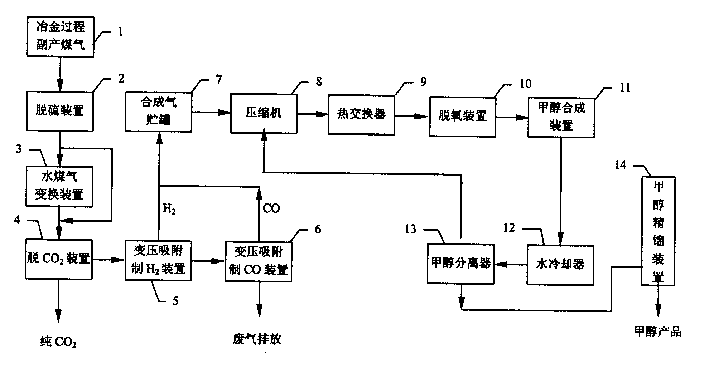

[0025] figure 1 Shown is the process flow chart of synthesizing methanol by using the by-product gas in the metallurgical process. The by-product gas 1 of the metallurgical process whose composition is shown in Table 1 passes through the desulfurization device 2 in turn. The desulfurization process is carried out by combining wet and dry desulfurization, the water-gas shift device 3, and the decarbonization device 4. The decarbonization process uses diethanolamine wet Decarbonization by decarbonization method, pressure swing adsorption hydrogen production unit 5, pressure swing adsorption CO production unit 6, synthesis gas storage tank 7, compressor 8, heat exchanger 9 and deoxygenation unit 10 process, the components are synthesized as shown in Table 1 Gas (H 2 , CO, CO 2 ), under the action of the methanol synthesis catalyst in the methanol synthesis unit, the methanol synthesis reaction occurs; the reacted gas can be cooled, gas-liquid separated and methanol rectified to...

Embodiment 2

[0033] It is basically the same as Example 1, except that the process by-product gas and its composition-adjusted synthesis gas are different, as shown in Table 2. The main products of the slurry bed methanol synthesis reaction are methanol and a small amount of methane, the single-pass conversion rate of CO can reach 56.5%, and the methanol selectivity is greater than 97%.

Embodiment 3

[0035] It is basically the same as Example 1, the difference is that the by-product gas in the process and its composition-adjusted syngas composition are different (as shown in Table 3) and methanol synthesis adopts a fixed-bed process (reaction conditions are 5MPa, 250°C, 10000h -1 ). The main products of the fixed-bed methanol synthesis reaction are methanol and a small amount of methane, the single-pass conversion rate of CO can reach 35%, and the methanol selectivity is greater than 95%.

[0036] Table 1

[0037] Gas Composition (%)

[0038]CO CO 2 h 2 N 2 o 2 Metallurgical process by-product gas I 25.0 15.6 2.3 56.0 0.1 Syngas I for methanol synthesis 32.19 3.22 64.37 0.23 -

[0039] Table 2

[0040] Gas Composition (%)

[0041] CO CO 2 h 2 N 2 o 2 Metallurgical process by-product gas II 50.8 18.0 1.5 29.5 1.2 Syngas II for methanol synthesis 24.71 0.99...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com