Mounting structure of fuel box for motor bicycle

A technology for motorized two-wheeled vehicles and fuel tanks, which is applied in the direction of machines/engines, liquid fuel feeders, and charging systems, and can solve the problems of not being able to use and not being able to use rotating support structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

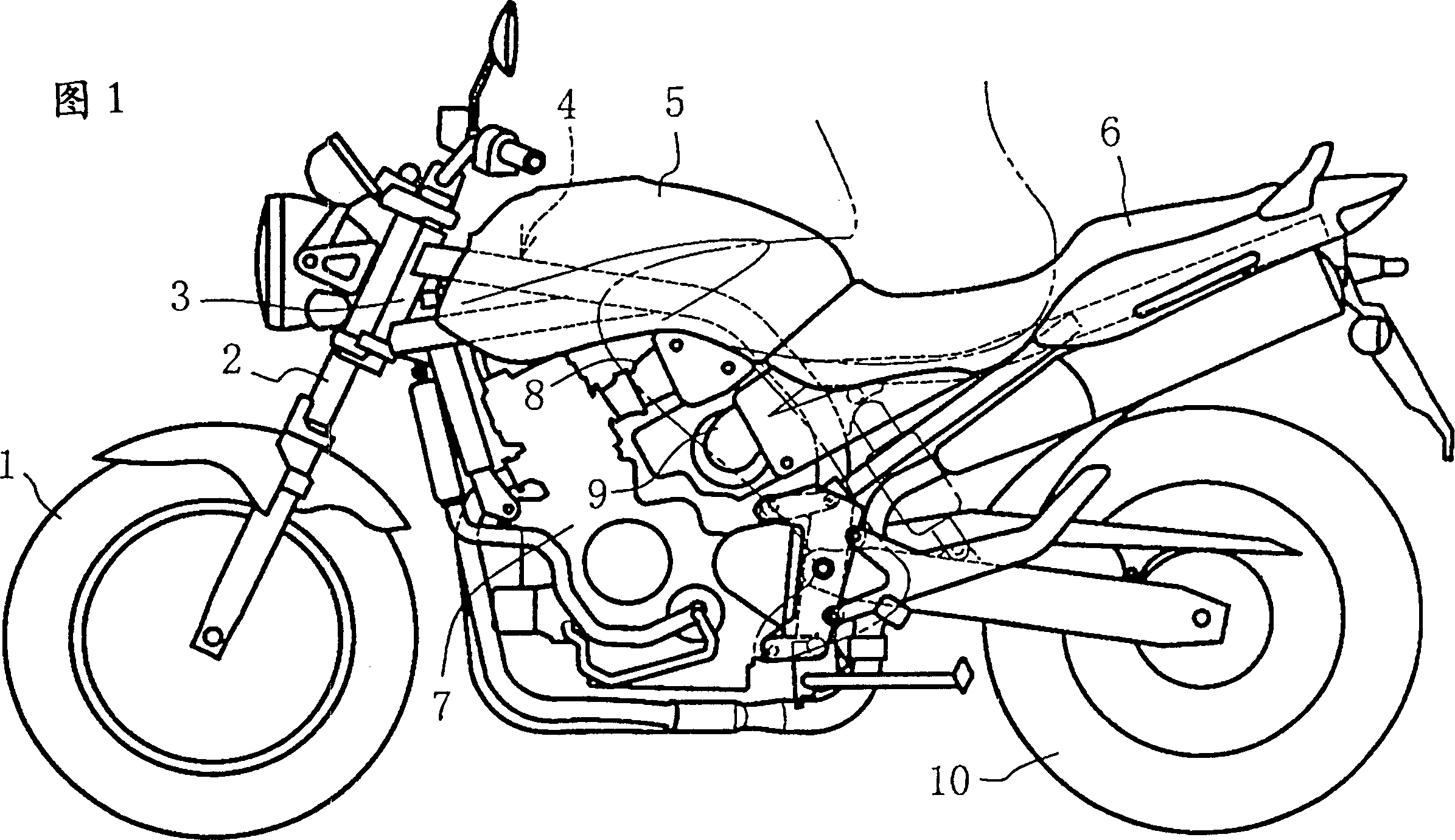

[0018] An embodiment is described below according to the accompanying drawings. Fig. 1 is a side view of a motorcycle to which this embodiment is applied, figure 2 is the side view of the fuel tank, image 3 It is a figure showing the state when the fuel tank turns, Figure 4 is the enlarged side view of the hinge, Figure 5 yes Figure 4 The 5-5 line sectional view, Image 6 is a cutaway view of the front of the fuel tank, Figure 7 It is an explanatory diagram of the operation of the hinge.

[0019] First of all, in Figure 1, the symbol 1 is the front wheel, 2 is the front fork, 3 is the head pipe, 4 is the single-cone body frame, 5 is the fuel tank, 6 is the seat, 7 is the engine, 8 Is the throttle body of the fuel injection device, 9 is the air filter, 10 is the rear wheel.

[0020] Such as figure 2 with image 3 As shown, the fuel tank 5 is equipped with a substantially U-shaped coupling member 11 opened forward on the side of the front end, and is freely disenga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com