Composite wall plate producing process and system

A production process and a complete set of equipment technology, applied in the direction of walls, layered products, manufacturing tools, etc., can solve the problems of uneven thickness of wall panels, climbing height, difficult to guarantee the shape and quality of wall panels, etc., to improve heat preservation and The effect of sound insulation and energy generation, increasing thermal insulation performance, improving external quality and thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

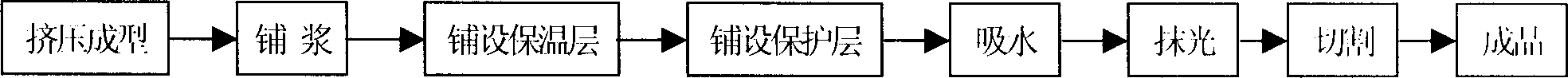

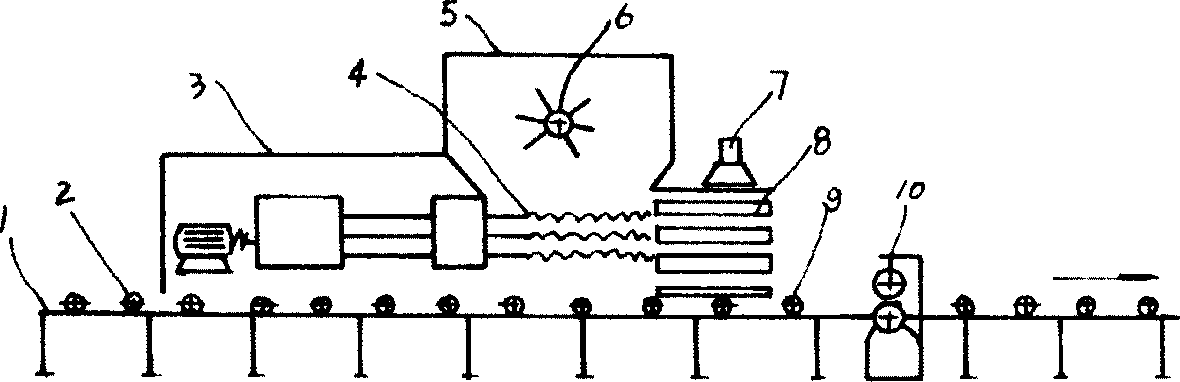

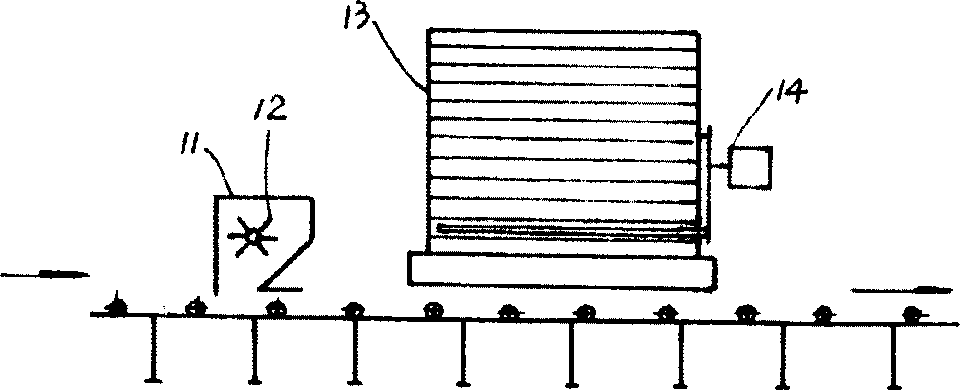

[0035] Composite wallboard production process of the present invention as shown in the figure:

[0036] Adjust the molding cavity and hinge cage according to the thickness of the wallboard specification and the number of layers of row holes, send the mortar material into the material box to extrude the molding board, and spread the cement paste layer on one of the board surfaces, and then put the cement paste layer on it. Lay polystyrene insulation board on top, and then lay a protective layer of mixed mortar on the insulation board to form a composite wallboard. After sucking out excess water in the mortar, the board surface is wiped off, traces are eliminated, and specification marks are printed, and the composite wallboard is cut. , It is sent to the curing kiln by the loading and unloading maintenance vehicle, and it is the finished product after leaving the kiln.

[0037] After a slight change in this process, the process of laying the insulation board can also be omitted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com