Melt near quick setting method and special apparatus

A special equipment and melt technology, which is applied in the field of near-rapid solidification of melt and special equipment, can solve the problems of insufficient smoothness of the sample surface, complex die-casting technology, and reduced cooling rate, etc., and achieve good filling effect, high density value, Effect of reducing jet resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

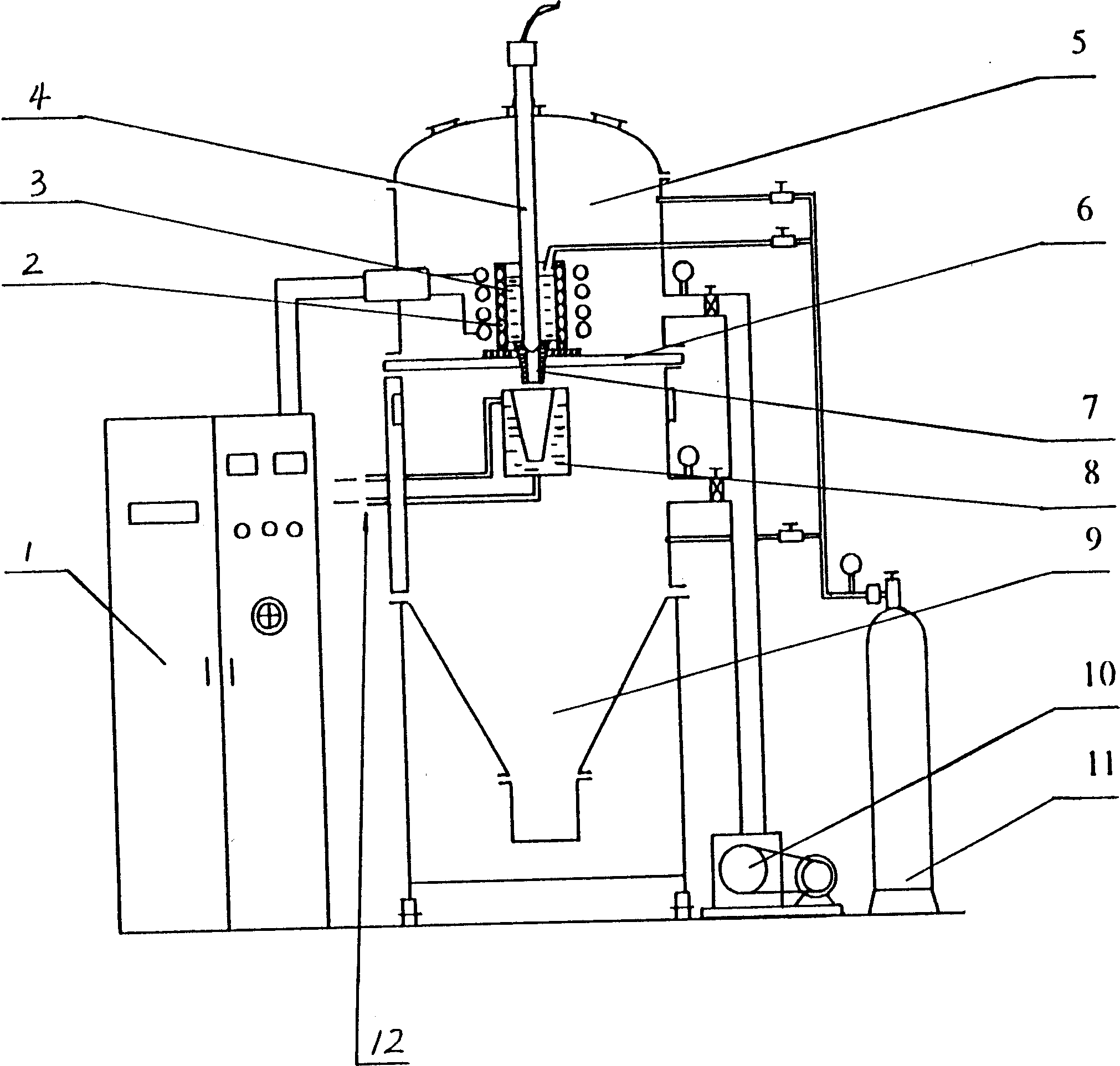

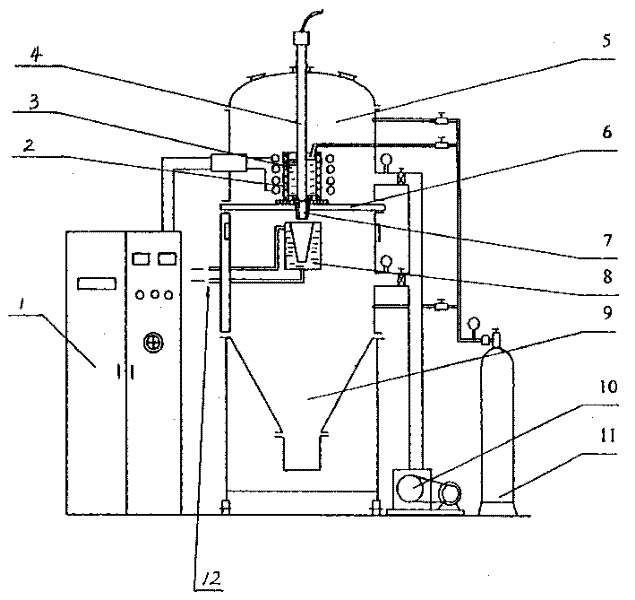

Method used

Image

Examples

Embodiment 1

[0026] The composition and atomic percentage of Zr-Cu-Ni-Al master alloy are: Zr 55 Cu 30 Ni 5 Al 10 , heating in a medium frequency induction furnace under vacuum conditions, the specific steps are as follows:

[0027] 1. Plug the guide tube with a plunger rod, and add the master alloy into the quartz crucible in the vacuum chamber;

[0028] 2. Start the vacuum device and the inflation device, repeatedly evacuate the upper and lower vacuum chambers and fill them with argon gas twice, and keep the vacuum degree at 5×10 -3 Pa;

[0029] 3. Start the intermediate frequency induction furnace and heat the master alloy to a temperature 100-120°C higher than the melting point;

[0030] 4. Pull up the plunger rod that blocks the crucible, inject positive pressure argon gas (its purity is 99.999%) above the melt for spray casting, the blowing pressure is 0.1MPa, and at the same time, the lower part of the alloy melt is subjected to high vacuum suction casting, The alloy melt is i...

Embodiment 2

[0033] The difference from Example 1 is:

[0034] The Zr-Cu-Ni-Al master alloy is heated in a medium frequency induction furnace under vacuum conditions, and the vacuum degree is 1×10 -3 Pa, when the melting point of the alloy is 50-80°C, the plunger is pulled out, the blowing pressure is 0.05MPa, the operation is the same as in Example 1, and an amorphous / nanocrystalline composite material with nanocrystalline precipitated phases in the amorphous matrix is prepared .

Embodiment 3

[0036] The difference from Example 1 is:

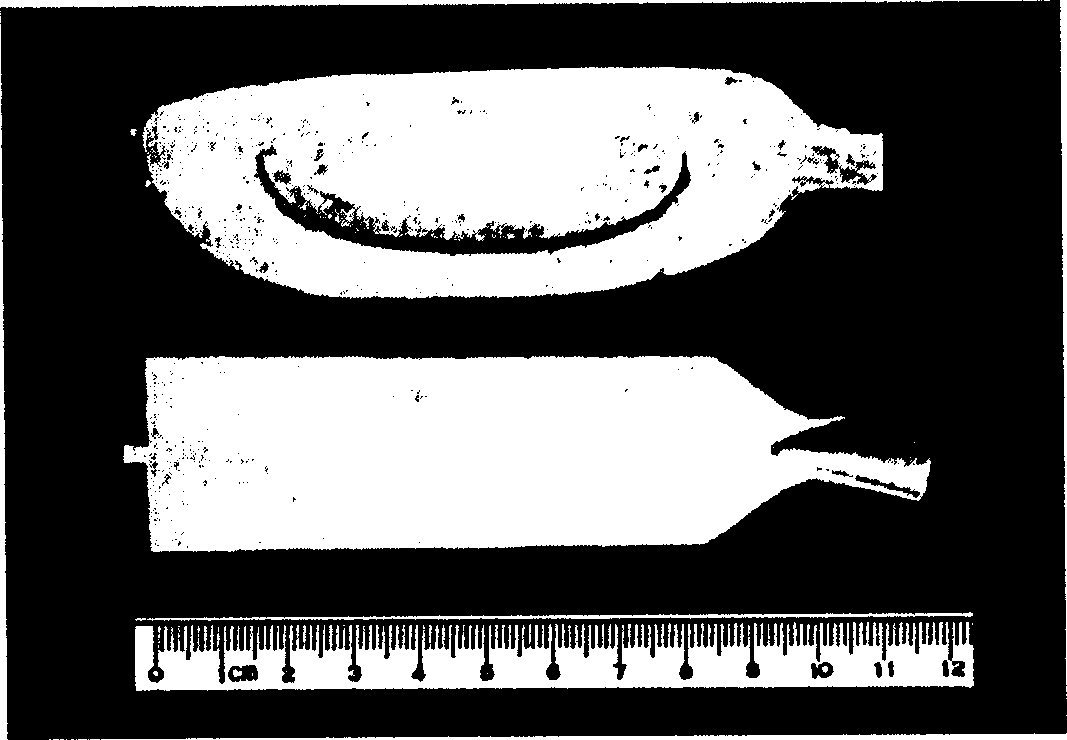

[0037] The operating conditions are the same as in Example 1. According to the shape of the mould, a large-scale plate of 30 × 4 × 100 (mm) and a golf racket head are inlaid with amorphous alloy special-shaped parts, such as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com