Method for construction of polyurethane track of sports field

A construction method and polyurethane technology, applied in the direction of polyurea/polyurethane coatings, sports accessories, roads, etc., can solve the problems of increased processing cost, waste of molded products, insufficient surface roughness, etc., and achieve the effect of fast construction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

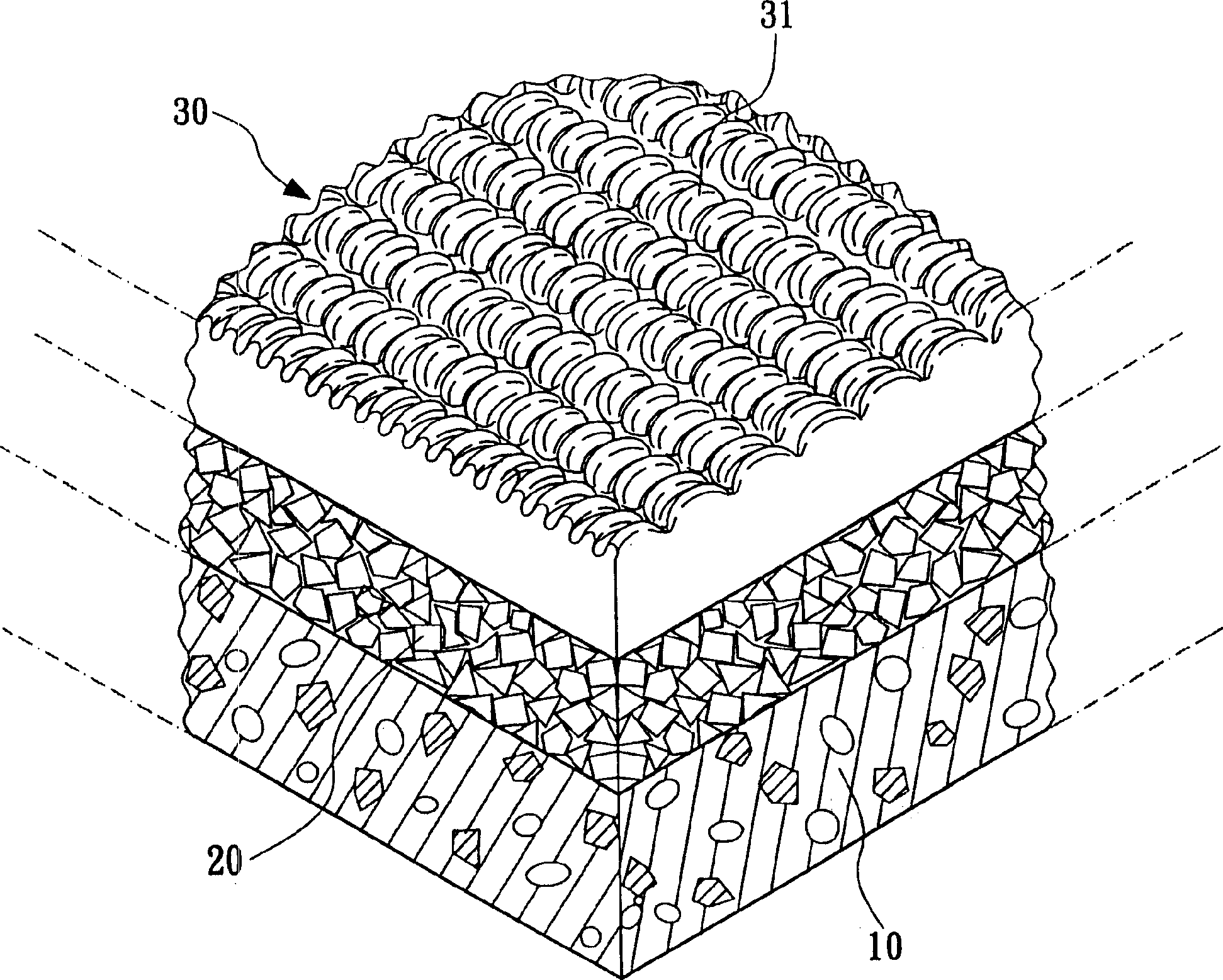

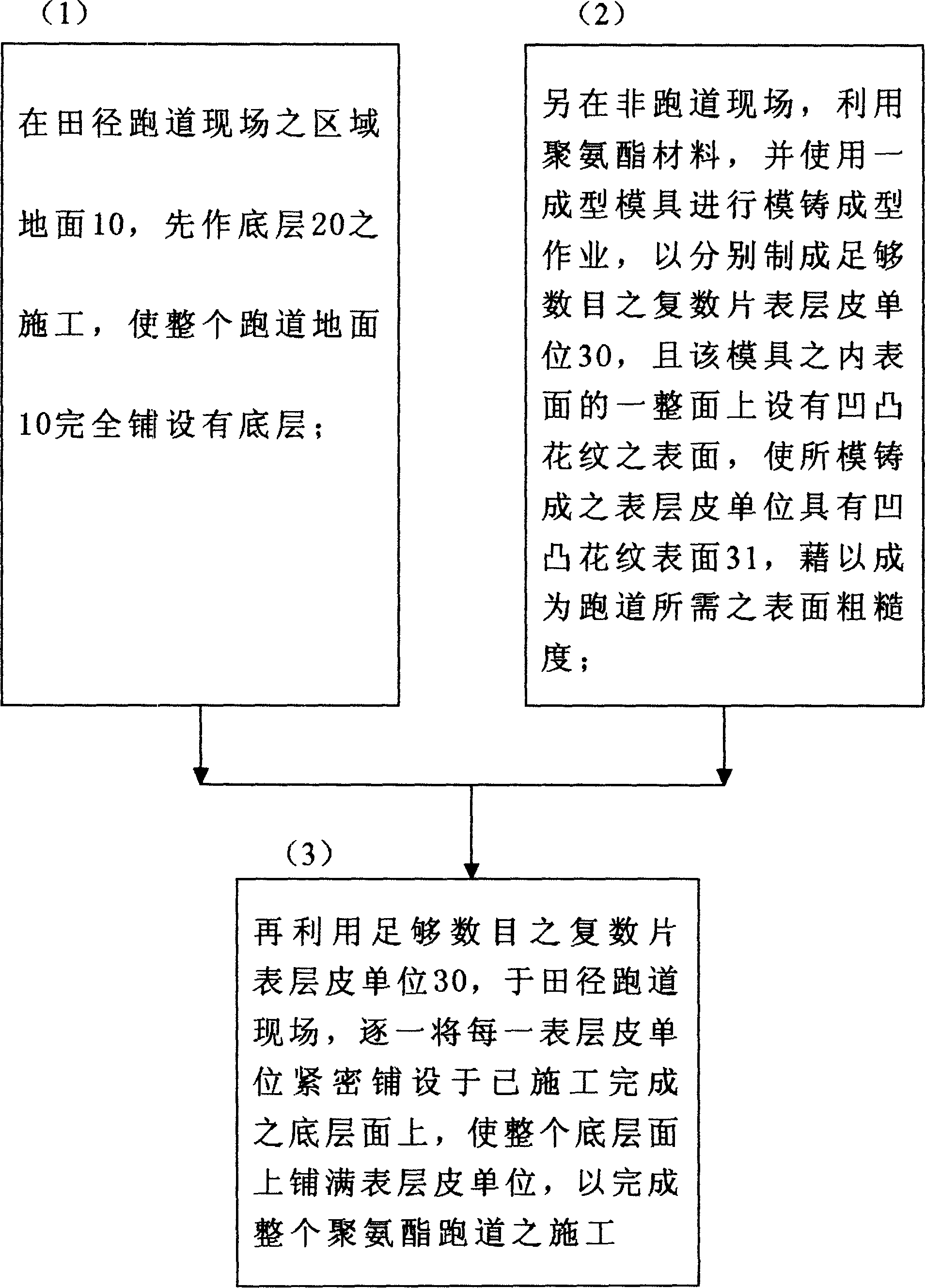

[0027] see figure 1 , figure 2 ,image 3, Figure 4 Shown, the present invention comprises the following steps:

[0028] (1) On the runway ground 10 of the track and field track site, the construction of the bottom layer 20 is done first, so that the entire runway ground 10 is completely covered with the bottom layer 20. For the construction of water slope or drainage system, etc., after the ground 10 is leveled, the bottom layer 20 is laid, and the bottom layer 20 can be all made of polyurethane particles, or mixed with polyurethane particles and rubber particles, and mixed with polyurethane as an adhesive. Stirring and mixing, and laying directly on the ground 10 to form the bottom layer 20 before hardening, and then allowing the bottom layer 20 to harden at natural temperature;

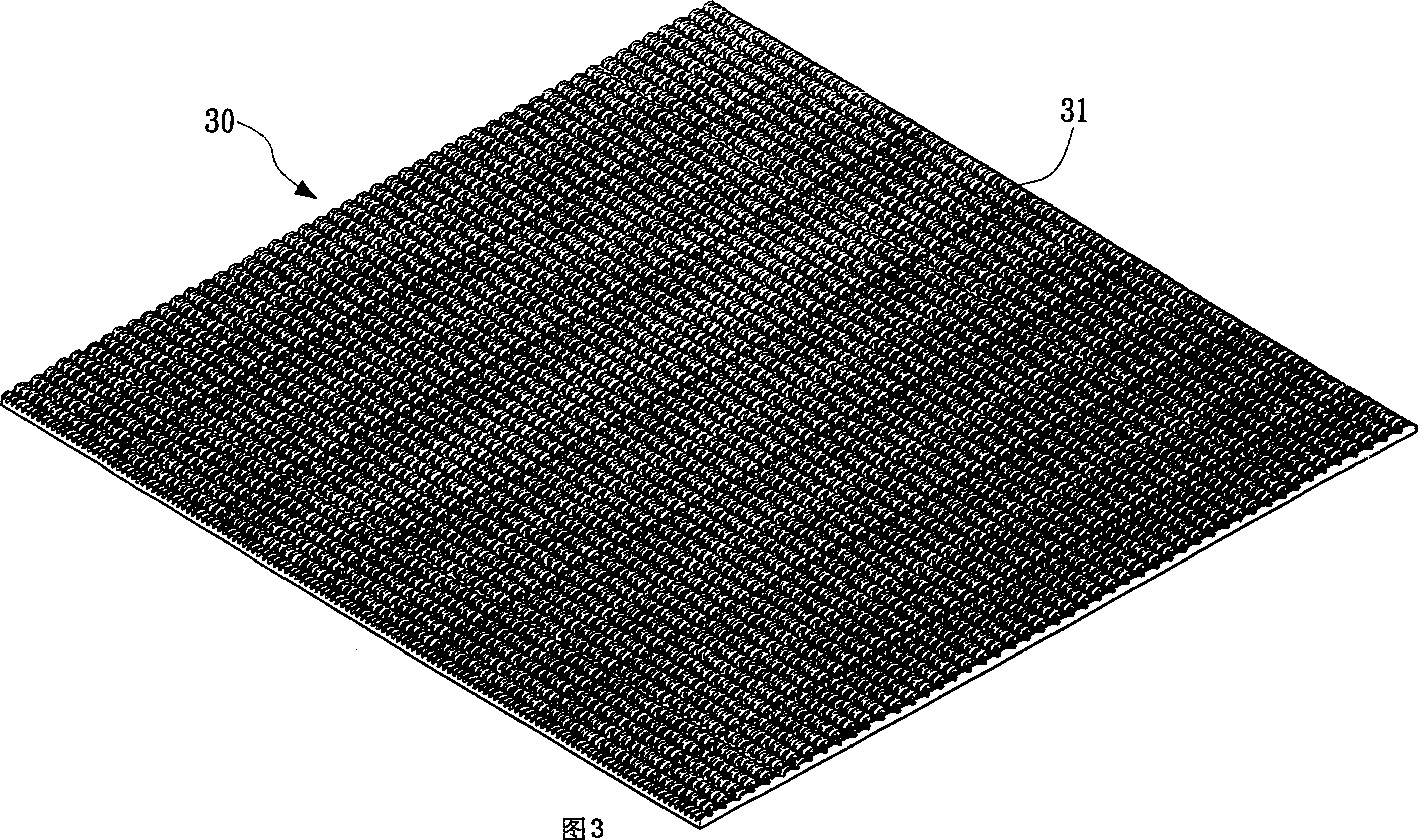

[0029] (2) In addition, on the non-track and field track site, polyurethane material is used, and a molding mold is used for molding operation, so as to make a sufficient number of plural surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com