Method for making electronic component using wet corrosion agent

A manufacturing method and technology for electronic components, which are applied in the fields of semiconductor/solid-state device manufacturing, electrical components, and photoengraving processes of patterned surfaces, can solve the problems of thin thickness, poor operability, and low rigidity, and achieve high etching accuracy and cost. Falling, cheap effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

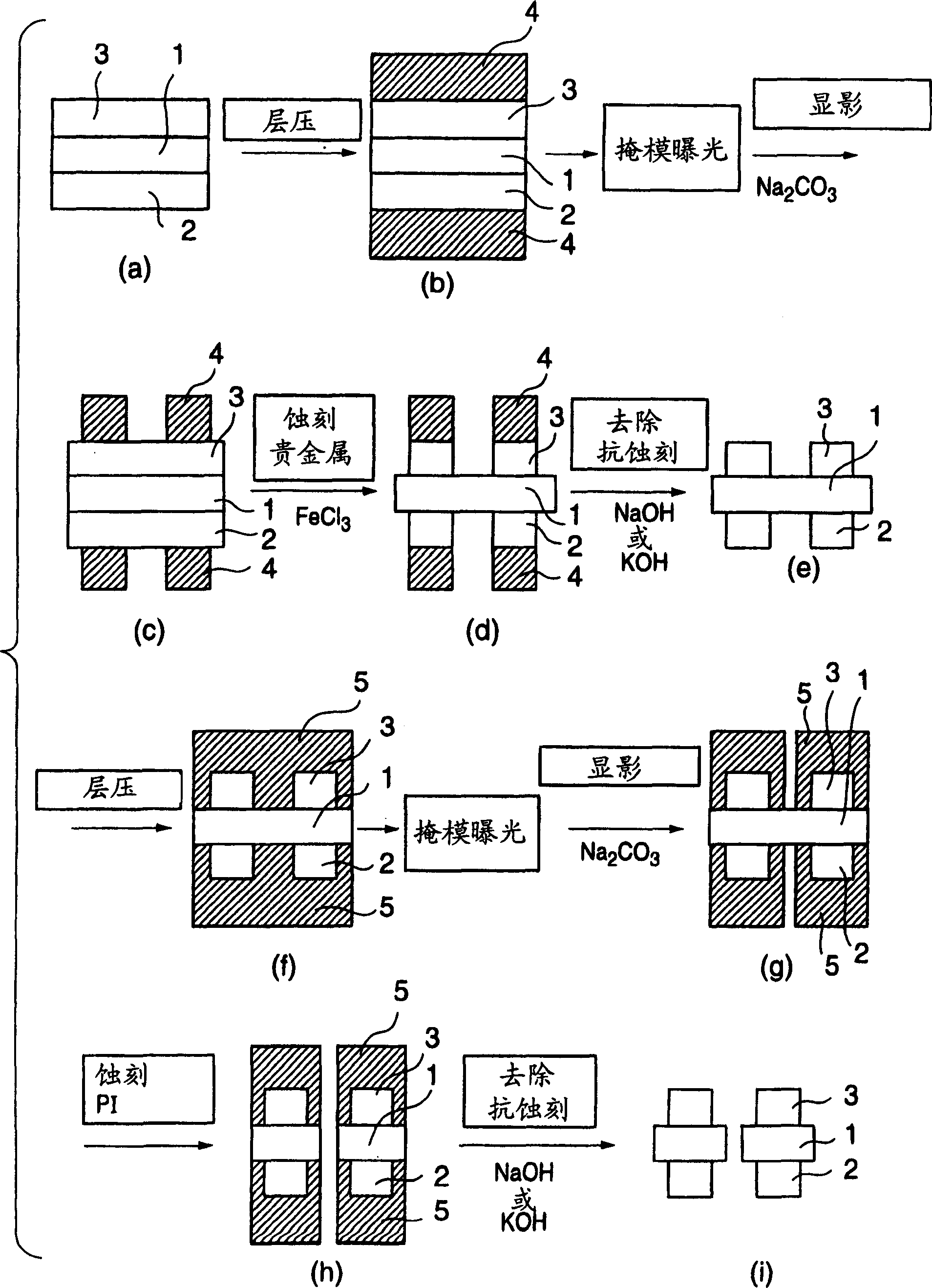

Method used

Image

Examples

Embodiment A

[0248] wet etchable laminate

[0249] [etching test]

[0250] In order to manufacture a sample for forming an insulating layer, a polyamic acid varnish manufactured by Mitsui Chemicals Co., Ltd.: PAA-A (trade name) and a polyimide varnish manufactured by Shin Nippon Chemical Co., Ltd.: EN-20 (trade name) were prepared as Adhesive resin. A polyimide film APIKAL NPI (trade name, thickness: 12.5 micrometers) manufactured by Kanebuchi Chemical Co., Ltd. was prepared as a low-expansion polyimide used as a core wire. Toray Engineering Co., Ltd. alkaline ammonia series polyimide etchant TPE-3000 (trade name) was prepared as an etchant used in the etching test.

[0251] On a SUS304 plate with a film thickness of 100 microns in a size of 15 cm x 15 cm, apply the adhesive resin Wanisu EN-20 (trade name) by spin coating to form a film thickness of 20 microns to 40 microns at 180° C. Oven dry for 30 minutes. Since PAA-A (trade name) is Amic acid wanis, the solvent was removed in a dry...

Embodiment B

[0324] [etching test]

[0325] In order to manufacture a sample for forming an insulating layer, Mitsui Chemicals Co., Ltd. polyamic acid: PAA-A (trade name) and Shin Nippon Chemical Co., Ltd. polyamide: EN-20 (trade name) were prepared as adhesive resins. A polyimide film APIKALNPI (trade name, thickness: 12.5 μm) manufactured by Kanebuchi Chemical Co., Ltd. was prepared as a low-expansion polyimide used as a core wire. Toray Engineering Co., Ltd. alkaline ammonia series polyimide etchant TPE-3000 (trade name) was prepared as an etchant used in the etching test.

[0326] On a SUS304 plate with a film thickness of 15cm×15cm and a film thickness of 100 microns, apply the adhesive resin ワニス by spin coating to form a film thickness of 20 microns to 40 microns, and dry EN-20 in an oven at 180°C ( product name, manufactured by Nippon Chemical Co., Ltd.) 30 minutes. PAA-A (trade name, manufactured by Mitsui Chemicals Co., Ltd.) is Amic acid wunis, so after removing the solvent in ...

Embodiment C

[0388] wet etchable laminate

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com