Antigravitational vacuum method and apparatus for asting Mg allor or Al alloy with lost mould

A technology of lost foam casting and vacuum lost foam, which is applied in the field of alloy precision casting and can solve problems such as unsuitability for mass industrial production, easy oxidation, and gas absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The melting furnace melts and refines the molten magnesium and aluminum alloy metal, and sends it into the pouring furnace through a siphon tube to keep warm and wait for pouring. The pouring furnace is filled with protective gas CO 2 , the pressure is 0.02mpa, and the vibration-tight sand box containing the foamed plastic casting pattern (lost foam) is sent to the top of the pouring table through rails or hoisting equipment, and the position is waiting for pouring. The sand box is vacuumed and then poured into the pouring furnace Inert gas CO with controlled pressure 2 , the pressure is 0.2mpa, and the vacuum degree is -0.04mpa when vacuuming, realizing anti-gravity vacuum casting. Example 2:

Embodiment 2

[0018] The melting furnace melts and refines the magnesium and aluminum alloy molten metal, and sends it into the pouring furnace through the electromagnetic pump to keep warm and wait for pouring. The pouring furnace is filled with protective gas Ar, the pressure is 0.008mpa, and the sand box is vacuumed, the vacuum degree is -0.06mpa, The inert gas that feeds into controllable pressure is also Ar, pressure 0.05mpa, other is the same as embodiment 1.

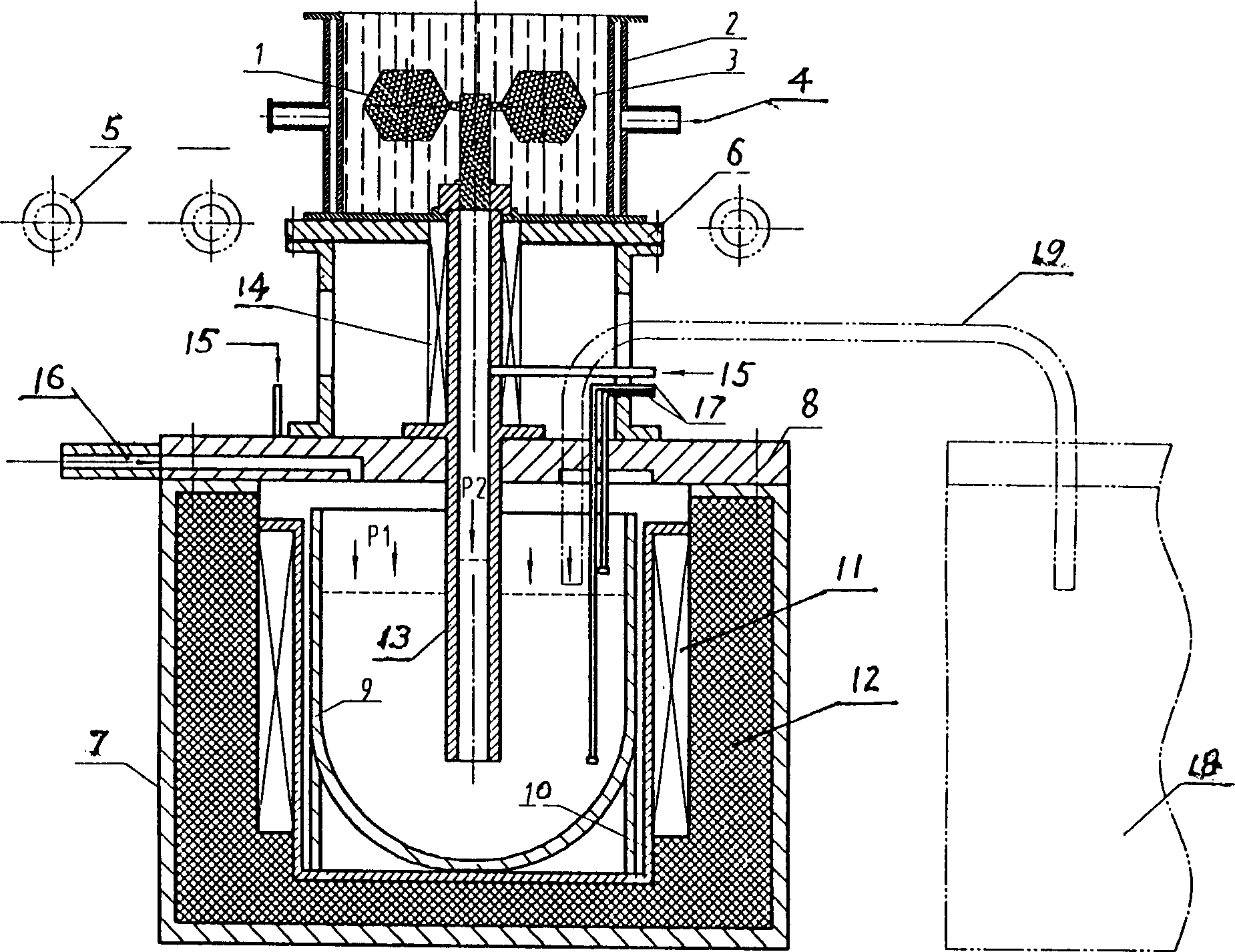

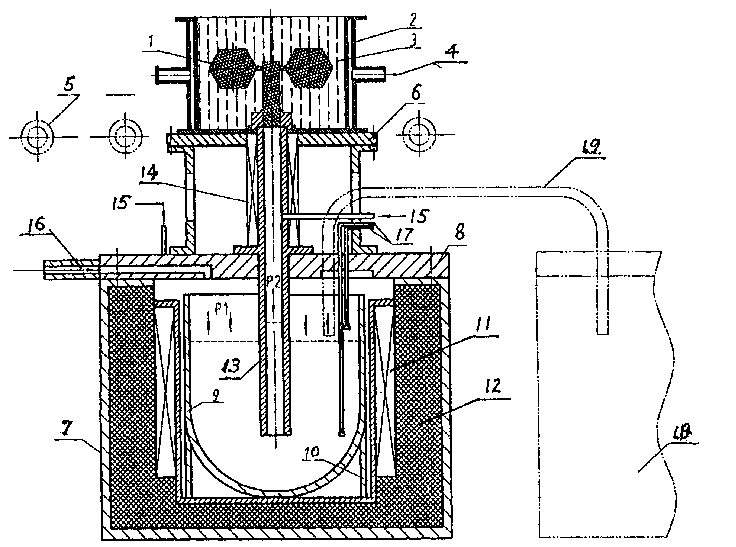

[0019] Equipment for anti-gravity vacuum casting such as figure 1 As shown, 1 is the lost foam casting pattern, 2 is the bottom injection sand box, 3 is the molding sand filled in it, 4 is the vacuum pipe for the sand box, 5 is the roller table for the mobile sand box, and 6 is the pouring platform. On the furnace cover 8 of the pouring furnace 7, 9 is the crucible, 10 is the stainless steel lining, 11 is the heating coil, 12 is the thermal insulation layer, 13 is the pouring tube, 14 is the thermal insulation heating coil, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com