Process for preparing antibacterial fibre of activated carbon containing nano silver particles

A technology of nano-silver particles and activated carbon fibers, applied in fiber processing, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of unreported nanoparticles and increase the complexity of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

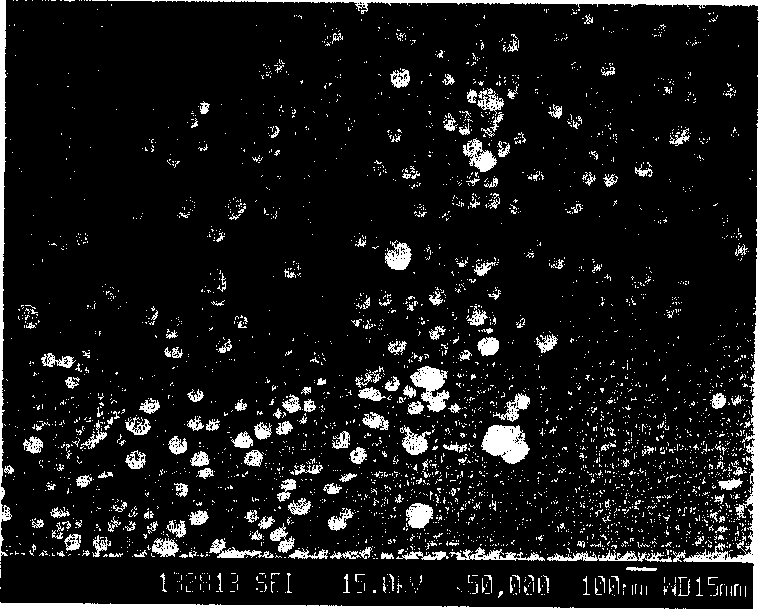

Image

Examples

Embodiment 1

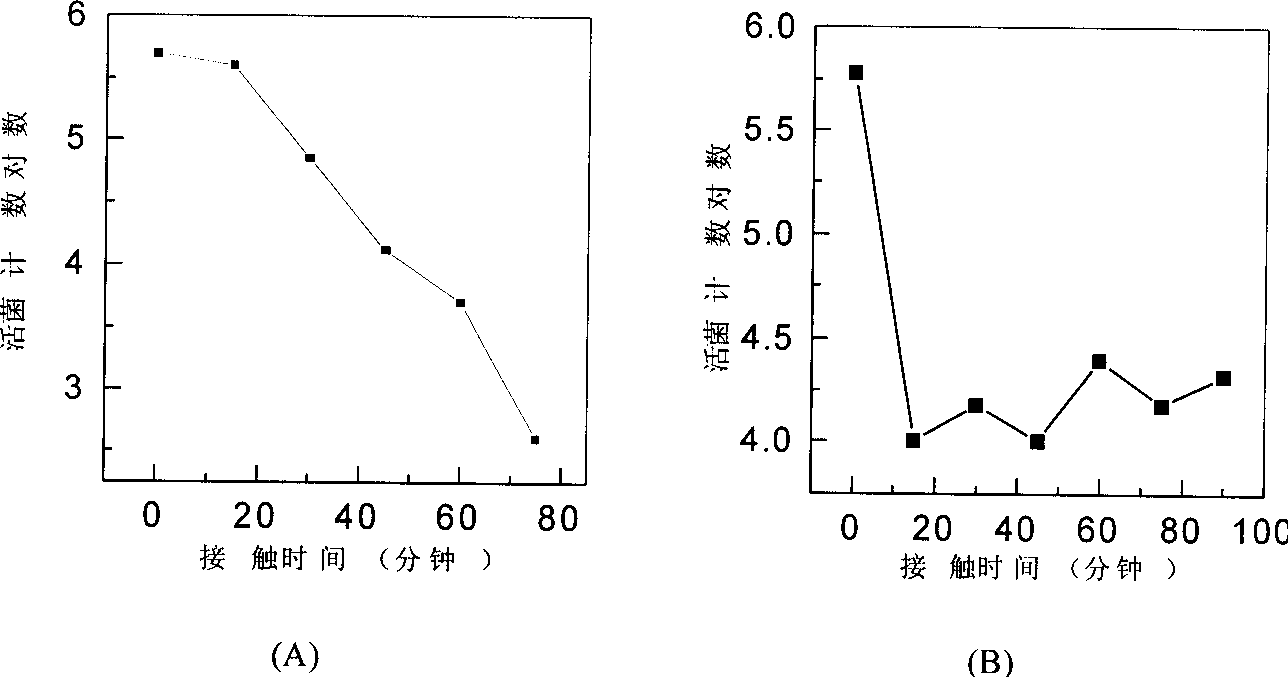

[0016] Using water vapor and phosphoric acid as activators, according to the method of the present invention, a series of sisal-based steam-activated activated carbon fibers SACF and phosphoric acid-activated activated carbon fibers HPSACF are prepared respectively by controlling the difference in activation time (15-120 minutes). Table 1 compares the sterilizing ability of these two series of silver-loaded activated carbon fibers. The initial concentration of E. coli in the solution = 5 × 10 8 cfu / ml (unit description: cfu is the abbreviation of English colony forming unit, which means colony forming unit, that is, the count of colonies), the contact reaction time is 8 hours, and the pH of the solution is 7.0. In the table, ∞ means that the number of bacteria is extremely large and cannot be counted (the same below). The results showed that all phosphoric acid-activated activated carbon fibers could completely kill Escherichia coli in the solution. Comparing the antibacteri...

Embodiment 2

[0019] Sisal fibers were soaked in 5% NaOH solution, then soaked in 30% phosphoric acid solution for 24 hours, and the fibers after the above treatment were carbonized and activated at 850°C for 1.5 hours under the protection of nitrogen to obtain a specific surface area of 800m 2 / g activated carbon fiber. After the activated carbon fiber was washed with dilute nitric acid, immersed in a solution containing 0.05% silver for 24 hours, the solution was filtered off, the fiber was fully washed, and vacuum-dried at low temperature to obtain activated carbon fiber HPSACF-80 with a silver loading of 20%. -Ag. In 20 ml containing E. coli count is 4 x 10 6 In the solution of cfu / ml, add this silver-loaded activated carbon fiber of different quality, the killing effect to Escherichia coli within 1 hour is as shown in Table 2. It can be seen from the data in the table that when the fiber dosage is only 20mg, the concentration of 20ml of bacteria-containing solution can be increased...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com