Prepn of oxygen-sensing sensor

A sensor and oxygen-sensitive technology, applied in the direction of material electrochemical variables, material resistance, etc., can solve the problems of narrow oxygen sensitivity range, different preparation methods, high working temperature, and achieve the effect of fast response, broad application prospects and low working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

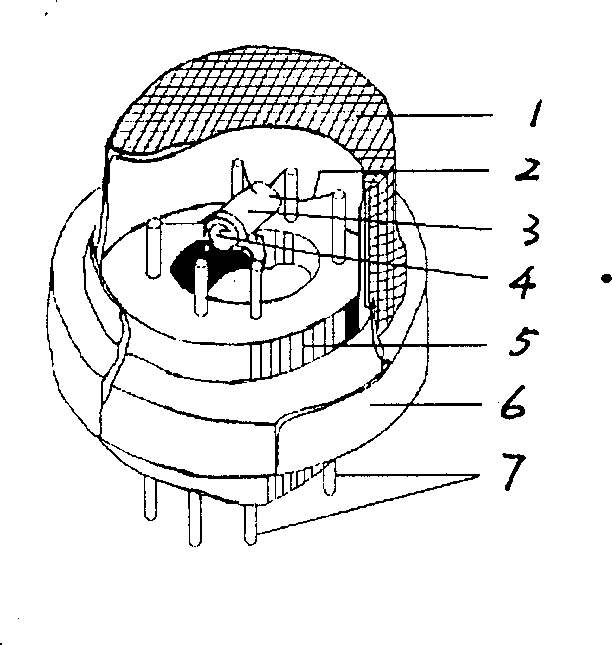

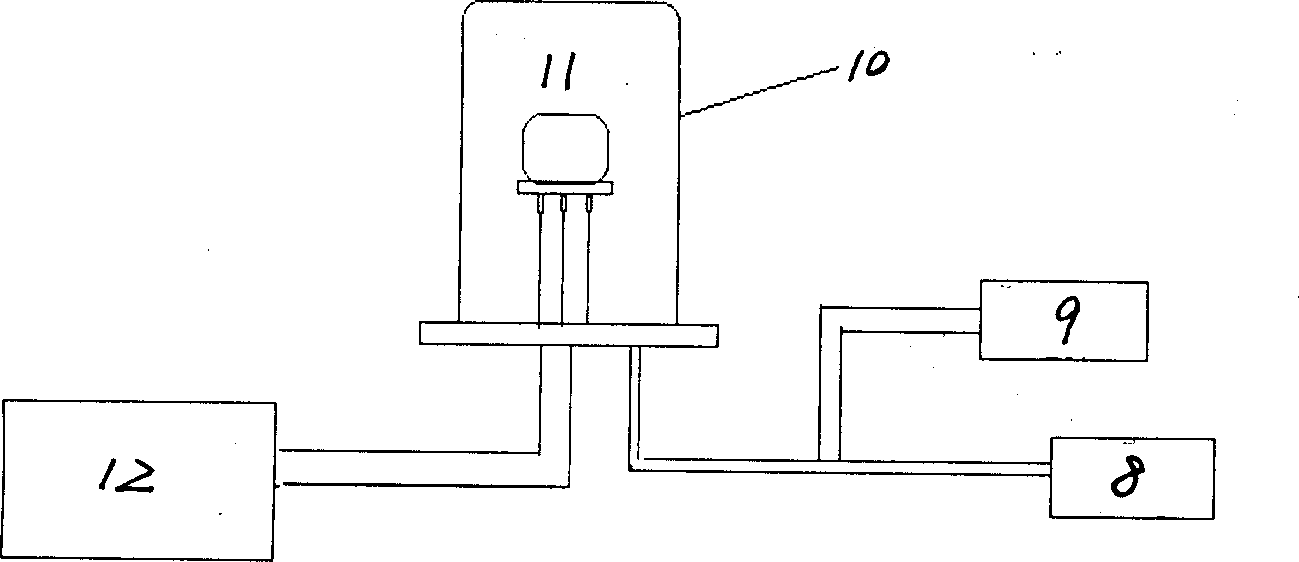

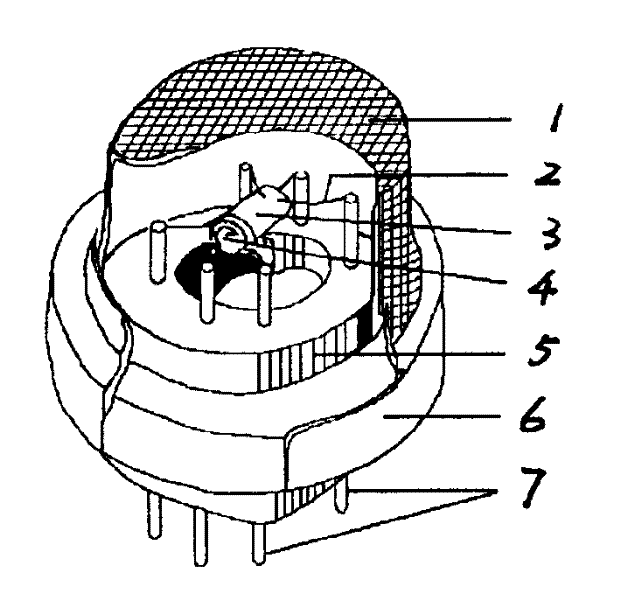

Method used

Image

Examples

Embodiment 1

[0036] (1) Using titanium trichloride (TiCl 3 ) (15% dissolved in HCl solution) and doped NbCl 5 When the source material is Nb:Ti=11:89 (molar ratio) (the above are analytically pure), fully stir in a 60°C water bath.

[0037] (2) add an appropriate amount of hydrogen peroxide (H 2 o 2 ) strong oxidant and DBS surface coating agent, stirred in a water bath at 60°C until a gel is formed, and kept warm for 3-5 hours.

[0038] (3) Prepare the gel in a vacuum oven at 80° C. and dry it for 12 hours.

[0039] (4) Grinding for 2 hours to make nanopowder. Pre-fire at 350°C for 1 hour to remove related organic matter.

[0040] (5) Prepare the above nano-powder with terpineol, and evenly spread it on the porcelain tube with the brush electrode to form a thick-film semiconductor element.

[0041] (6) Thick-film components are placed in a muffle furnace and sintered at 400°C for 1 hour. Its structure is determined by X-ray powder diffraction to be pure rutile phase, the grain size i...

Embodiment 2

[0044] (1) Using titanium trichloride (TiCl 3 ) (15% dissolved in HCl solution) and doped NbCl 5 When Ta:Ti=4:96 (molar ratio) as the source material (the above are analytically pure), fully stir in a 60°C water bath.

[0045] (2) add an appropriate amount of hydrogen peroxide (H 2 o 2 ) strong oxidant and DBS surface coating agent, stirred in a water bath at 60°C until a gel is formed, and kept warm for 3-5 hours.

[0046] (3) Prepare the gel in a vacuum oven at 80° C. and dry it for 12 hours.

[0047] (4) Grinding for 2 hours to make nanopowder. Pre-fire at 350°C for 1 hour to remove related organic matter.

[0048] (5) Prepare the above nano-powder with terpineol, and evenly spread it on the porcelain tube with the brush electrode to form a thick-film semiconductor element.

[0049] (6) Thick-film components are placed in a muffle furnace and sintered at 400°C for 1 hour. Its structure is determined by X-ray powder diffraction to be pure rutile phase, the grain size ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com