Harmless treating and resource utilizing method for waste salt-containing drilling slurry in oil field

A waste mud and treatment method technology, applied in chemical instruments and methods, sludge treatment, waste treatment, etc., can solve problems such as salt ion adsorption, and achieve the effect of saving land resources and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

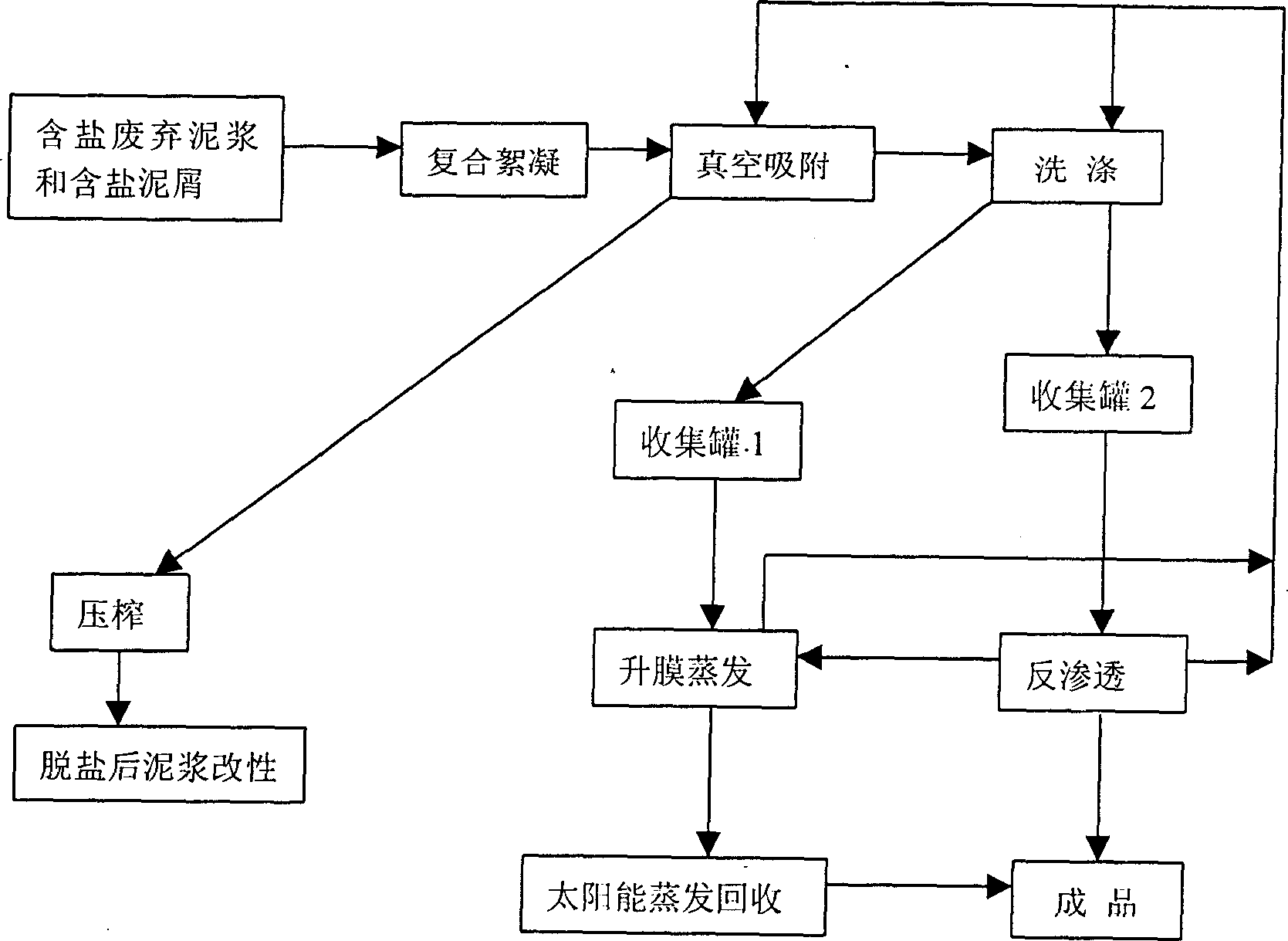

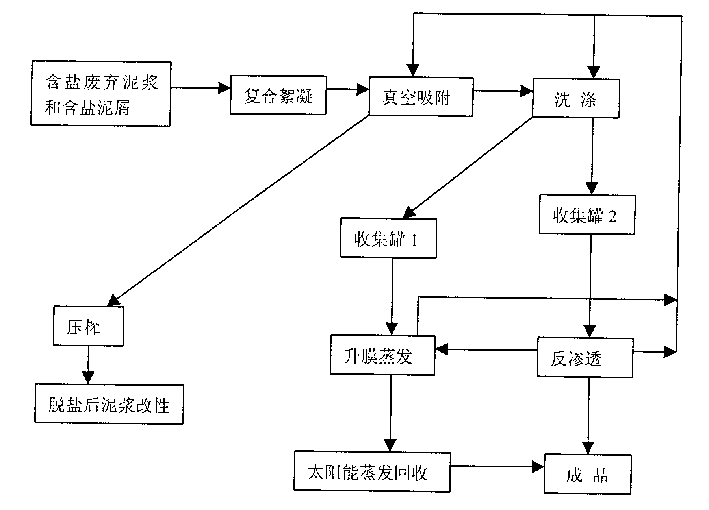

Image

Examples

Embodiment Construction

[0048] 1. Take 10 tons of saline waste mud and saline mud from drilling. And add 4 tons of water for dilution. Use a screw pump to inject into a flocculation tank with a volume of 10 tons.

[0049] 2. Prepare 1 ton of 0.1% polyacrylamide and 0.5 ton of 5% polyaluminum chloride.

[0050] 3. Add all the flocculants prepared in 1 and 2 into 10 tons of mud, stir for 3 minutes, and control the stirring speed at 15 rpm.

[0051] 4. Dehydrate the flocculated mud with a belt press vacuum dehydration equipment. The vacuum degree is controlled at 0.3 atmospheres. After the detached water is collected with a concentrated brine collection tank, it is washed four times. The first and second washing The concentrated brine is collected into the concentrated brine storage tank, and the third and fourth wash water are collected into the light brine storage tank. The salt ion concentration after mud washing is 260mg / L.

[0052] 5. Squeeze the desalted mud, modify the squeezed mud cake, (1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com