Film packed nonaqueous electrolyte battery with improved surface treated lead terminal

A non-aqueous electrolyte and lead terminal technology, which can be used in the manufacture of non-aqueous electrolyte batteries, aqueous electrolyte batteries, and electrolyte batteries, etc., can solve the problems of surface corrosion of lead terminals, decreased adhesion of sealant layers and lead terminals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

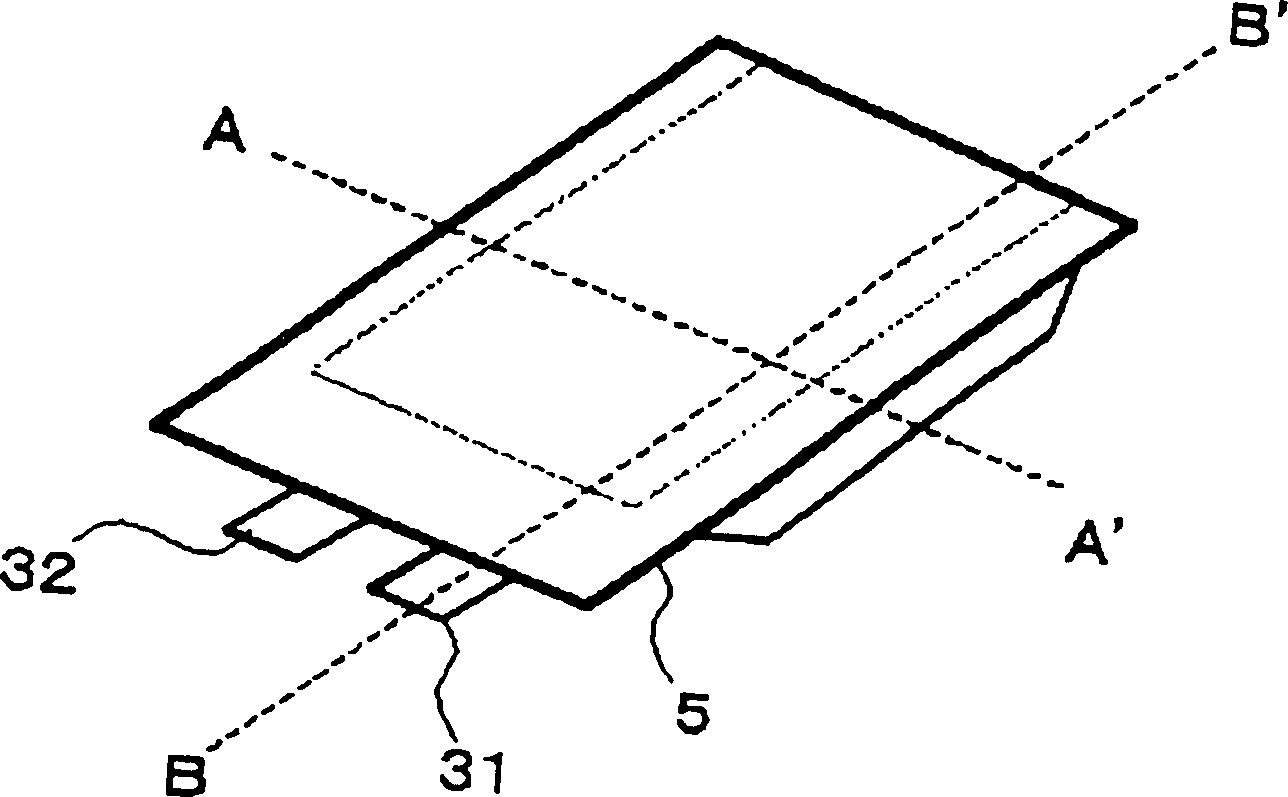

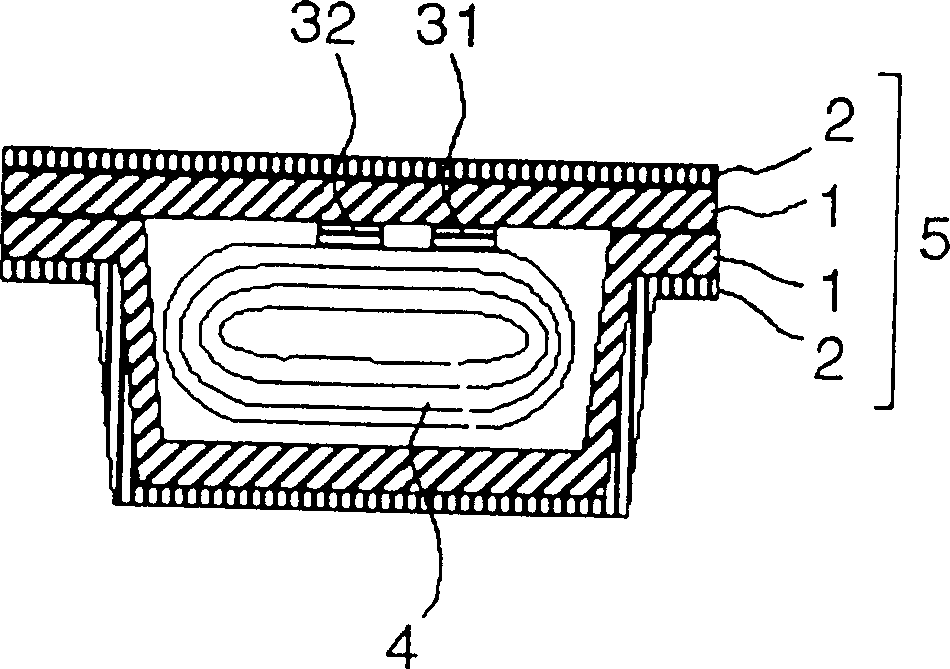

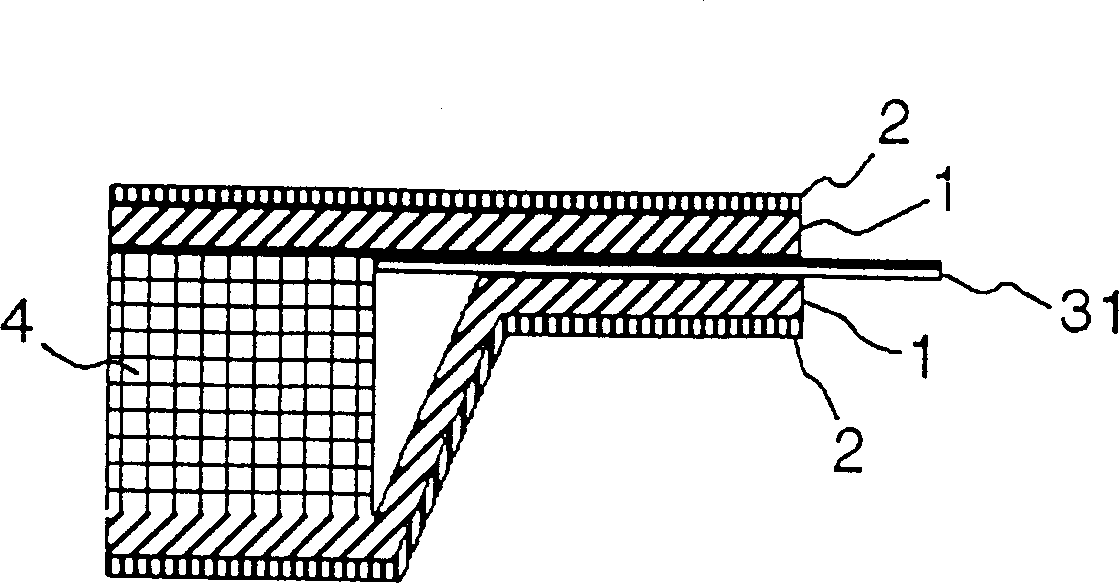

[0054] A preferred embodiment according to the present invention will be described in detail with reference to the accompanying drawings. figure 1 is a schematic perspective view of a film-sealed non-aqueous electrolyte battery in a preferred embodiment of the present invention. figure 2 are instructions along the figure 1 The cross-sectional front view of the film-encapsulated non-aqueous electrolyte battery taken along line A-A' of . image 3 are instructions along the figure 1 The enlarged fragmentary cross-sectional front view of the film-encapsulated non-aqueous electrolyte battery taken along line B-B' of .

[0055] The film-encapsulated non-aqueous electrolyte battery mainly includes a battery element 4 and a membrane case 5 sealing the battery element 4 . The battery element 4 includes a nonaqueous electrolyte, a positive electrode, a negative electrode, and a separator. The film case 5 further includes a laminated structure of a sealant polymer resin film 1, a me...

Embodiment 1

[0093] Lithium manganese oxide powder with spinel structure, carbon donor for generating electrical conductivity, and polyvinylidene fluoride are blended in a weight ratio of 90:5:5 to form N-methylpyrrolidone (hereinafter referred to as NMP ). The NMP is then stirred to form a slurry comprising NMP. The amount of NMP is adjusted according to the viscosity of the slurry. The slurry was uniformly applied onto the first surface of a 20-micrometer-thick aluminum foil serving as a positive electrode collector using a doctor blade, followed by drying at 100° C. for 2 hours under vacuum pressure. The slurry was additionally applied to the second surface of the aluminum foil, followed by drying under vacuum pressure. The sample was then wound and pressed to form a positive electrode active material layer. The theoretical capacity is 600mAh.

[0094] Amorphous carbon powder and polyvinylidene fluoride were blended at a weight ratio of 91:9 to form N-methylpyrrolidone (hereinafter ...

Embodiment 2

[0101] Lithium manganese oxide powder with spinel structure, carbon donor for generating electrical conductivity, and polyvinylidene fluoride are blended in a weight ratio of 90:5:5 to form N-methylpyrrolidone (hereinafter referred to as NMP ). The NMP is then stirred to form a slurry comprising NMP. The amount of NMP is adjusted according to the viscosity of the slurry. The slurry was uniformly applied onto the first surface of a 20-micrometer-thick aluminum foil serving as a positive electrode collector using a doctor blade, followed by drying at 100° C. for 2 hours under vacuum pressure. The slurry was additionally applied to the second surface of the aluminum foil, followed by drying under vacuum pressure. The sample was then wound and pressed to form a positive electrode active material layer. The theoretical capacity is 600mAh.

[0102] Amorphous carbon powder and polyvinylidene fluoride were blended at a weight ratio of 91:9 to form N-methylpyrrolidone (hereinafter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com