Active carbon producing method with city garbage and carbonizing furnace

A technology for producing activated carbon and municipal waste, applied in the fields of carbon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low economic benefits, no fundamental elimination of pollution sources, and high carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

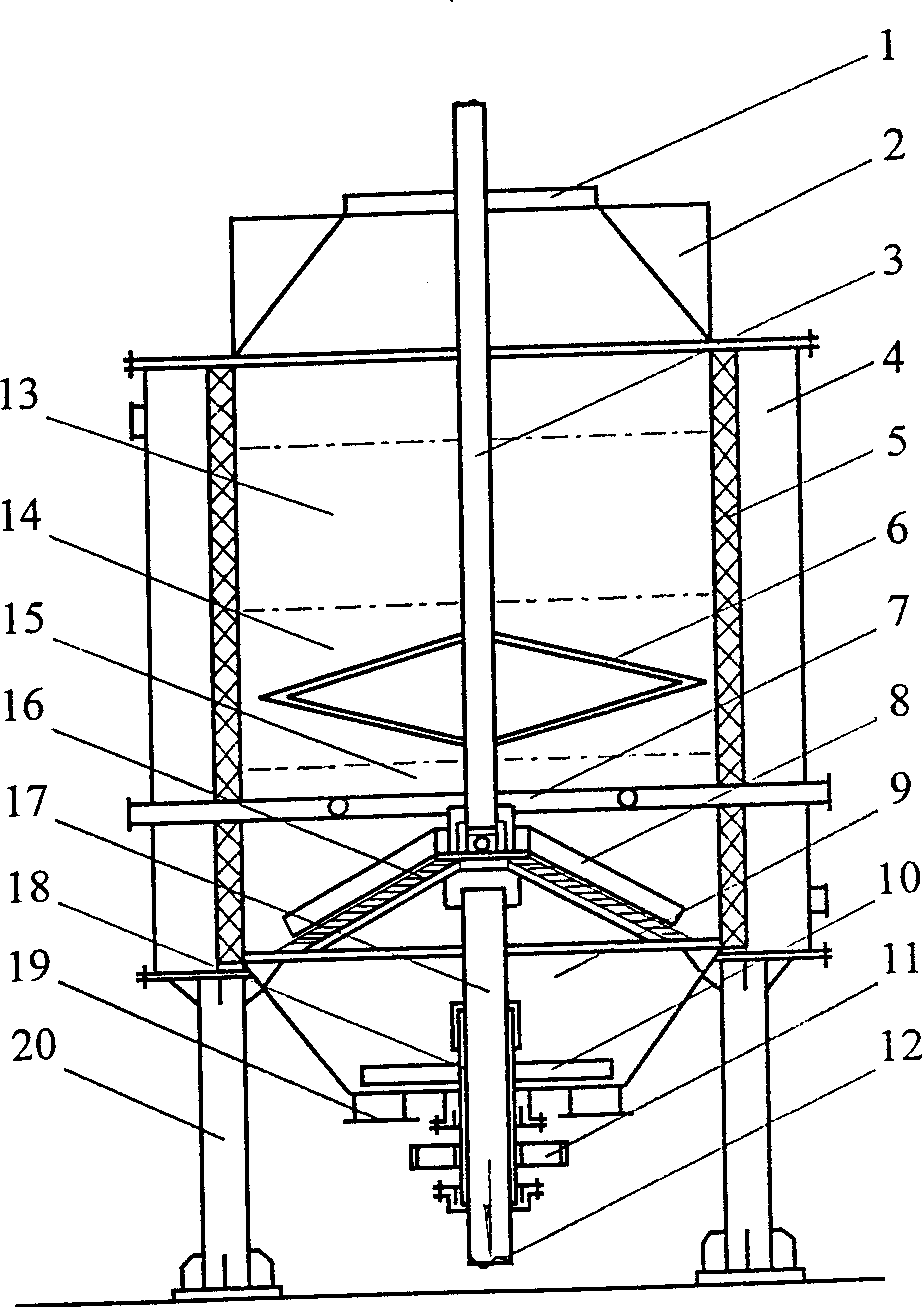

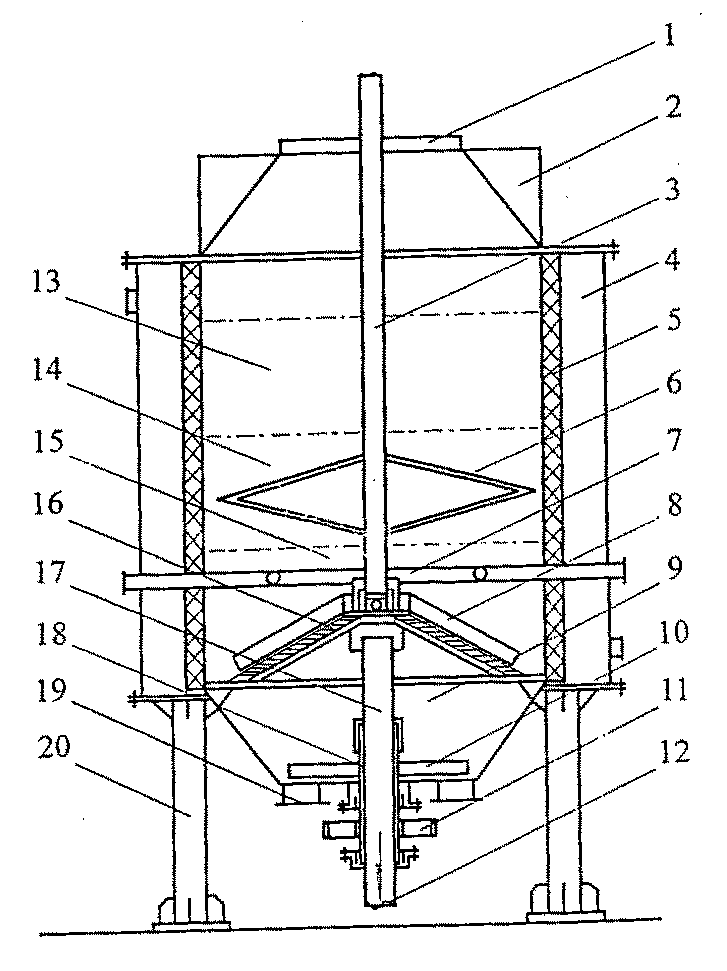

[0011] The carbonization furnace that uses urban garbage and organic waste to produce activated carbon has an inner diameter of 2.4 meters and a height of 6.8 meters. The urban domestic garbage and organic waste are roughly broken and then screened to remove waste metals (copper, iron, etc.) and Inorganic substances such as waste glass, broken bricks, stones, etc., are then pulverized, dehydrated (dried), compressed into bulk raw materials by mechanical extrusion, put into the above-mentioned carbonization furnace, and oxidized in the upper part of the furnace at about 1200 ° C. The gasification reaction is first carried out at the high temperature of the layer, and the combustible gas such as carbon monoxide after the gasification reaction is continuously pumped into the semi-coke-shaped high-temperature carbonized layer at the lower part of the reduction layer and mixed with the water vapor in the water vapor coil installed on this layer Activate the carbon in the semi-coke (...

Embodiment 2

[0014] The carbonization furnace for producing activated carbon from municipal garbage and organic waste has an inner diameter of 1.8 meters and a height of 5.4 meters. The urban domestic garbage and organic waste are roughly broken and then screened to remove waste metals (copper, iron, etc.) and waste Inorganic substances such as glass, broken bricks, stones, etc., are then pulverized, dehydrated (dried) and compressed into massive raw materials by mechanical extrusion, and added to the above-mentioned carbonization furnace. Next, the gasification reaction is carried out first, and the combustible gas such as carbon monoxide after the gasification reaction is continuously sucked into the semi-coke-shaped high-temperature carbonized layer at the lower part of the reducing layer, and is mixed with the water vapor in the steam coil installed in this layer to activate the layer Activated carbon (crude product) is produced from the carbon in the semi-coke-like (900°C) high-tempera...

Embodiment 3

[0017] The carbonization furnace that uses urban garbage and organic waste to produce activated carbon has an inner diameter of 1.2 meters and a height of 4.6 meters. The urban domestic garbage and organic waste are roughly broken and then screened to remove waste metals (copper, iron, etc.) and waste. Inorganic substances such as glass, broken bricks, stones, etc., are then pulverized, dehydrated (dried) and compressed into massive raw materials by mechanical extrusion, and added to the above-mentioned carbonization furnace. Next, the gasification reaction is carried out first, and the combustible gas such as carbon monoxide after the gasification reaction is continuously sucked into the semi-coke-like high-temperature carbonized layer at the lower part of the reducing layer, and is mixed with the water vapor in the steam coil installed in this layer to activate the layer. The carbon in the semi-coke (900°C) high-temperature carbonization layer produces activated carbon (crude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com