Sealed getter

A getter, inert gas technology, used in biological packaging, transportation and packaging, special packaging objects, etc., can solve problems such as getter failure, and achieve a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

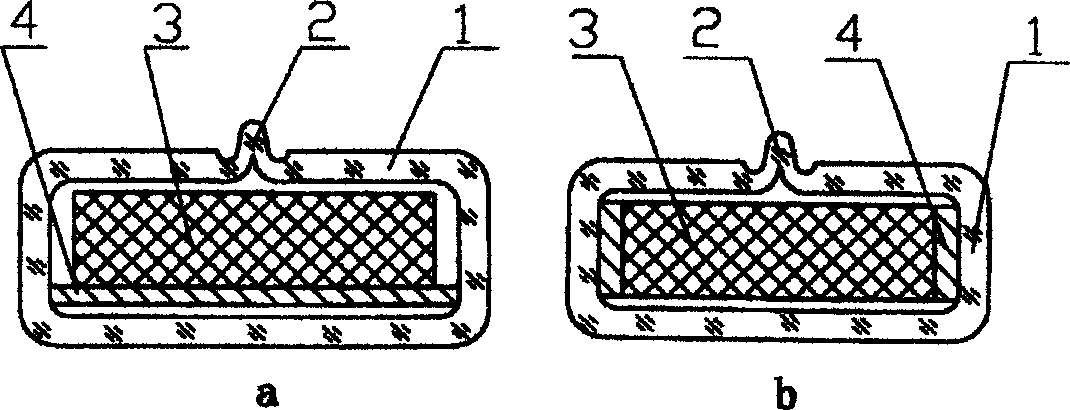

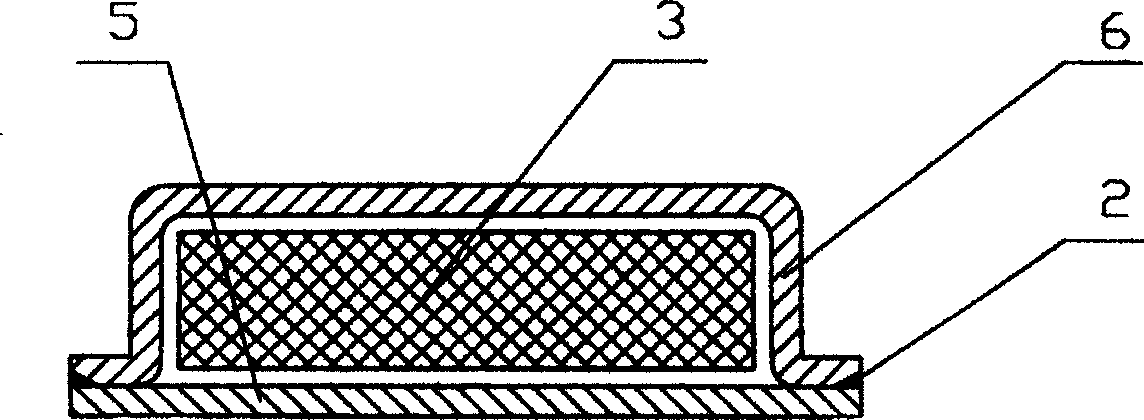

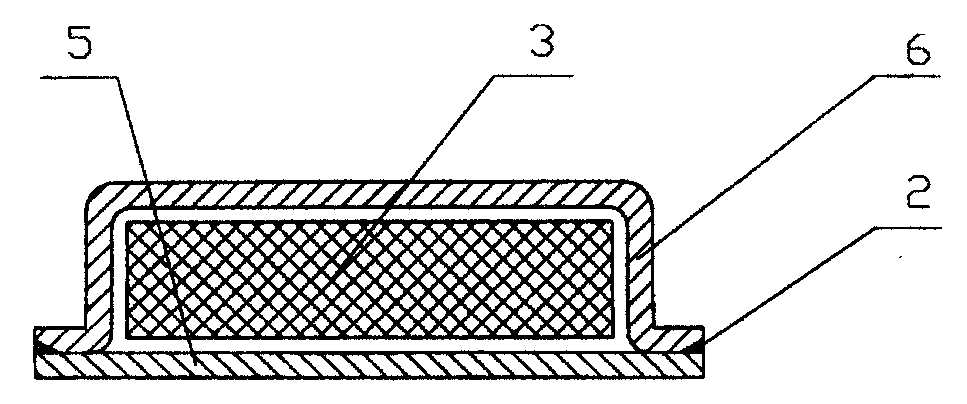

[0011] figure 1 (a) and (b) are schematic diagrams of the structure of the glass-encapsulated getter. Put the stainless steel sheet or ring 4 and the getter block 3 assembly in the glass thin tube 1, seal it tightly in a vacuum state, seal the exhaust pipe 2, or directly put the getter block 3 into the glass tube 1, Carry out vacuum treatment and seal after filling with inert gas. of the present invention figure 2 Shown is a schematic diagram of the structure of the getter encapsulated by the metal material. Place the getter block 3 in the groove of the dish-shaped bowl 6 of the encapsulation container, cover the sealing sheet 5, fix the periphery by spot welding first, put it into the vacuum equipment for vacuum treatment, or fill it with inert gas to carry out Perimeter seal welded. The encapsulation process of the above two types of encapsulated getters is as follows: 1. Getters of corresponding sizes applied to different vacuum devices are prepared. 2. Select the enc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com