Conductive adhesion agent, assembling structure and method for making said assembling structure

A technology for conductive adhesives and assembling structures, applied in conductive adhesives, conductive adhesive connections, printed circuit manufacturing, etc., can solve the problem of increased connection resistance, increased volume specific resistance of conductive adhesives, and easy vulcanization of silver. and other problems to achieve the effect of avoiding connection resistance and avoiding increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0123] This embodiment provides the flip-chip assembly structure of the present invention for a semiconductor element. Such as figure 2 As shown, the assembled structure includes a printed circuit board 6 (which is an example of an electrical structure), and a semiconductor element 7 (which is another example of an electrical structure). The semiconductor element 7 includes an IC substrate 8 and bump electrodes 9 formed on the surface of the IC substrate 8 . The printed circuit board 6 has an I / O terminal electrode 10 on its surface. The I / O terminal electrode 10 has formed thereon the conductive adhesive layer 1A made of the conductive adhesive 1 described in the first embodiment. I / O terminal electrodes 10 and bump electrodes 9 are electrically connected through layer 1A. Furthermore, a sealing resin 11 is provided to fill the gap between the semiconductor element 7 and the printed circuit board 6, thereby constituting a flip-chip assembly structure.

[0124] ...

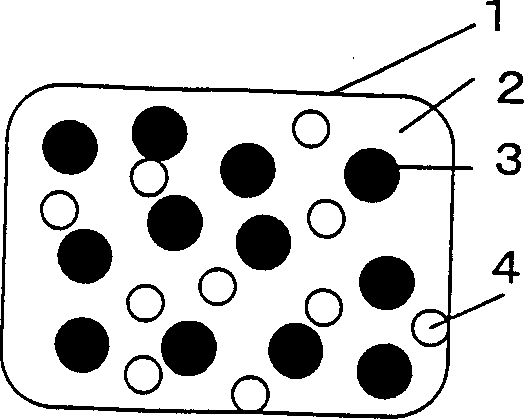

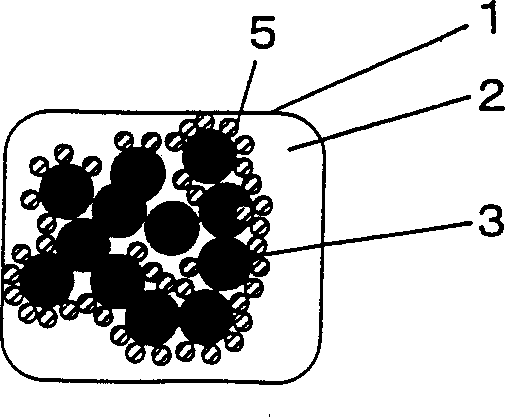

Embodiment 1

[0129] Through this practical example, the conductive adhesive 1 described in the first embodiment is characterized by the elution-preventing film forming agent 4, which is an anthranilic acid (melting point: 143°C ≈ activation temperature) as its The main component of the liquid reagent, anthranilic acid is a chelating agent. Anthranilic acid reacts with Ag microparticles to form silver anthranilate, which is a metal complex, on the surface of the microparticles. Note here that the activation temperature (reaction temperature) of anthranilic acid, the service temperature of the conductive adhesive, and the curing temperature of the conductive adhesive satisfy the following relationship:

[0130] The use temperature of the conductive adhesive (32°C) is less than the activation temperature of anthranilic acid (143°C); and

[0131] The activation temperature (143°C) of anthranilic acid is equal to or less than the curing temperature (150°C) of the binder resin.

[0132] Theref...

Embodiment 2

[0135] As a feature of this practical example, in the composition of the conductive adhesive described in practical example 1, the anti-elution film forming agent is 1-nitroso-2-naphthol (melting point: 110° C.) The anti-elution film forming agent 4,1-nitroso-2-naphthol as the main component is used as a chelating agent instead of anthranilic acid. Other conditions are exactly the same as those in Practical Example 1, ie, the constitutional conditions of the conductive adhesive material, the manufacturing method, the use temperature, the curing temperature, and the like.

[0136] The activation temperature (reaction temperature ≈ melting point) of 1-nitroso-2-naphthol is about 110°C, and when the binder resin 2 is cured, 1-nitroso-2-naphthol reacts with the conductive particles 3, A metal complex is formed, that is, the elution prevention membrane 4 has 1-nitroso-2-naphthol silver as its main component. Silver 1-nitroso-2-naphthol is an ionizing material in water and readily ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com