Non-symmetry structure for seven-layer laminated coiling-resistant composite film

An asymmetric structure, film structure technology, applied in the field of multi-layer co-extrusion blown composite film, can solve the problems of difficult to grasp the anti-curling effect, easy to produce film curling, stress imbalance, etc., achieve significant technological progress, overcome curling , Ingenious and unique effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

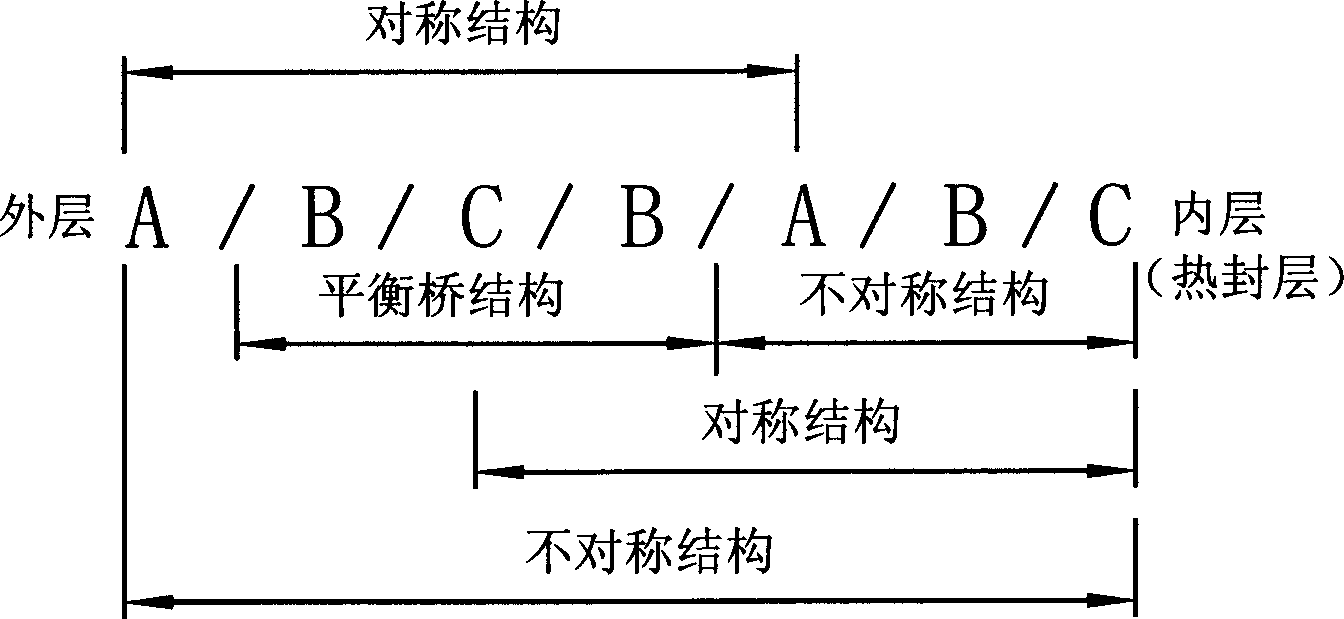

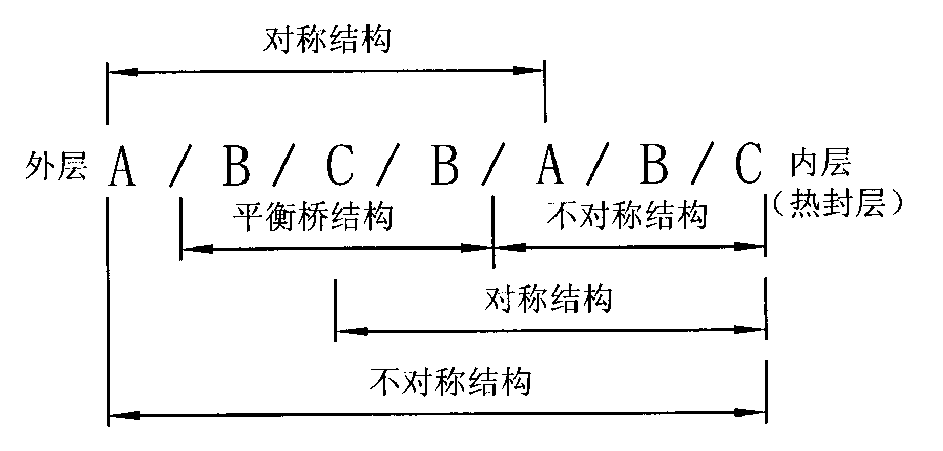

[0031] Embodiment 1: an asymmetric structure of a seven-layer co-extruded composite film, its structural expression is: A 1 / B 1 / C 1 / B 1 / A 1 / B 1 / C 1

[0032] In the above formula: the two crystalline resin layers A use the same crystalline resin material A 1 ; The two amorphous resin layers C use the same amorphous resin material C 1 ; Three adhesive resin layers B adopt the same adhesive resin material B 1 .

[0033] The specific structure of the seven-layer co-extruded composite film is: PA / Ti / PE / Ti / PA / Ti / PE. Among them, PA represents nylon oxygen barrier layer; Ti represents adhesive resin layer; PE polyethylene water barrier layer. It can be seen from this that the 2nd, 3rd, and 4th layers are balanced bridge structures that balance the stress and control the curling of the film, and a symmetrical structure is formed between the core 3rd layer and the 7th layer in this structure. The balance bridge structure is inserted into the original nylon outer layer, ...

Embodiment 2

[0034] Embodiment 2: An asymmetric structure of a seven-layer co-extruded composite film, its structural expression is: A / B / C 1 / B / A / B / C 2

[0035] In the above formula: two non-crystalline resin layers adopt two different non-crystalline resin materials C 1 、C 2 The two crystalline resin layers A use the same crystalline resin material; the three adhesive resin layers B use the same adhesive resin material.

[0036] The specific structure of the seven-layer co-extruded composite film can be: PA / Ti / PE / Ti / PA / Ti / LLDPE.

[0037] In the formula: PA represents nylon oxygen barrier layer; Ti represents adhesive resin layer; PE polyethylene water barrier layer; LLDPE represents linear low density polyethylene water barrier layer. It can be seen from this that the 2nd, 3rd, and 4th layers are balanced bridge structures that balance the stress and control the curling of the film, and a symmetrical structure is formed between the core 3rd layer and the 7th layer in this structure. ...

Embodiment 3

[0039] Embodiment three: an asymmetric structure of a seven-layer co-extrusion composite film, its structural expression is: A 1 / B / C / B / A 2 / B / C

[0040] In the above formula: two crystalline resin layers A use two different crystalline resin materials A 1 、A 2 The two non-crystalline resin layers C use the same non-crystalline resin material; the three adhesive resin layers B use the same adhesive resin material.

[0041] The specific structure is: PP / Ti / PE / Ti / PA / Ti / PE.

[0042] Another example is the specific structure: COPA / Ti / PE / Ti / PA / Ti / PE.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com