Jack catch for paw type chuck

A jaw chuck and jaw technology, which is applied in the field of jaws of jaw chucks, can solve the problems of unqualified jaws and poor quality of jaws, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

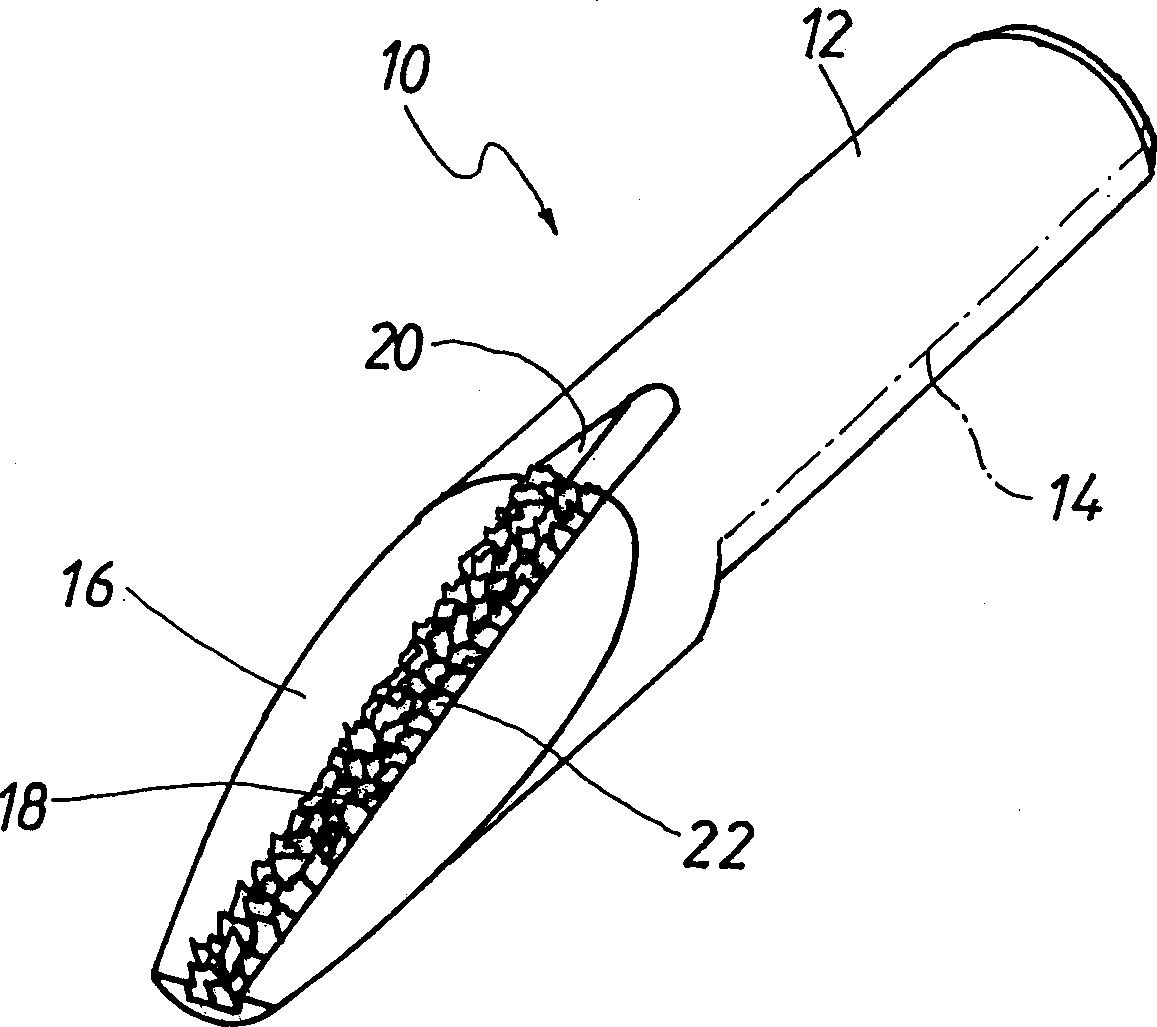

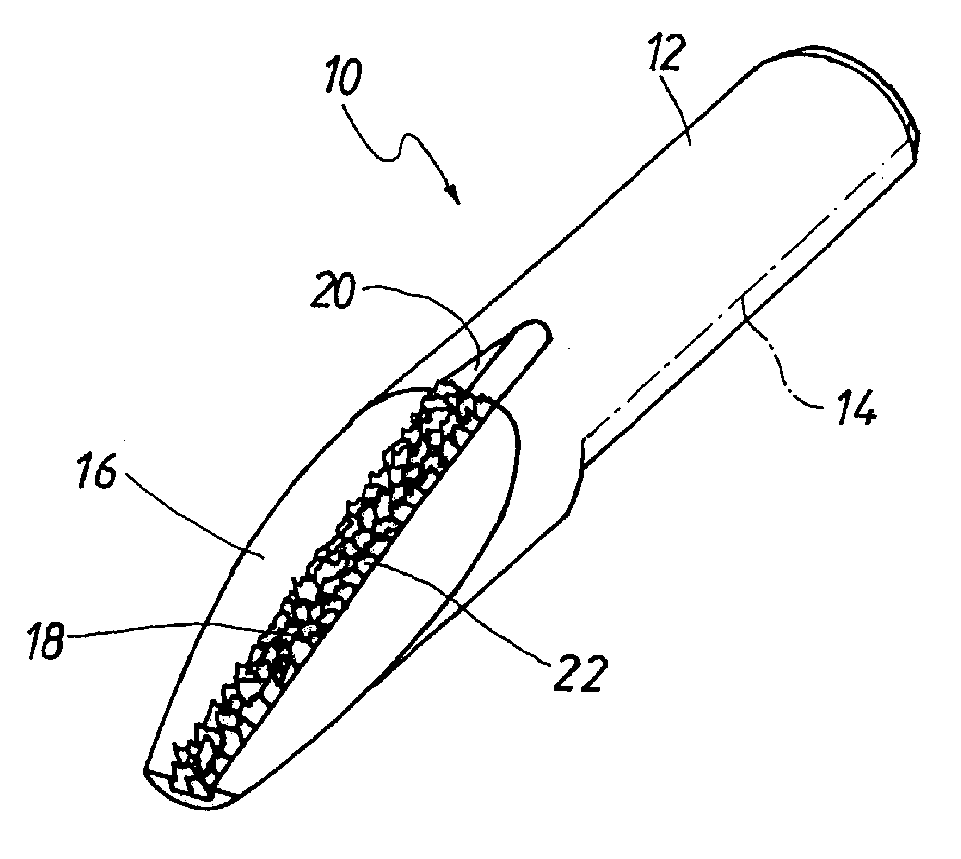

[0010] The claw 10 according to the present invention in the drawings includes a steel base 12, which is substantially cylindrical. Rack-shaped teeth 14 are provided on the side of a part of the length of the jaw 10 to move the jaw 10, for example, when a drill is clamped in a drill chuck (jaw chuck). The tooth 14 is indicated by a dash-dotted line in the figure. On the opposite side of the face where the tooth 14 is located, the end of the claw 10 is an inclined face 16. The clamping surface 18 of the jaw is formed by arranging a longitudinal groove 20 on the inclined surface 16 of the base 12 of the jaw 10, and the hard metal particles 22 are embedded in the longitudinal groove and connected to the base by hard welding. The hard metal particles 22 include angular hard metal particles that form the clamping surface 18. If the setting of the hard metal particles 22 after the brazing is not so precise, the hard metal particles 22 can be shaped by grinding after the brazing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com