Starting procedure of open-loop vactor control in synchronous machine

A synchronous motor and vector control technology, applied in the starter, vector control system, motor generator control and other directions of a single synchronous machine, can solve the problem of not eliminating system errors, and achieve the effect of reliable starting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

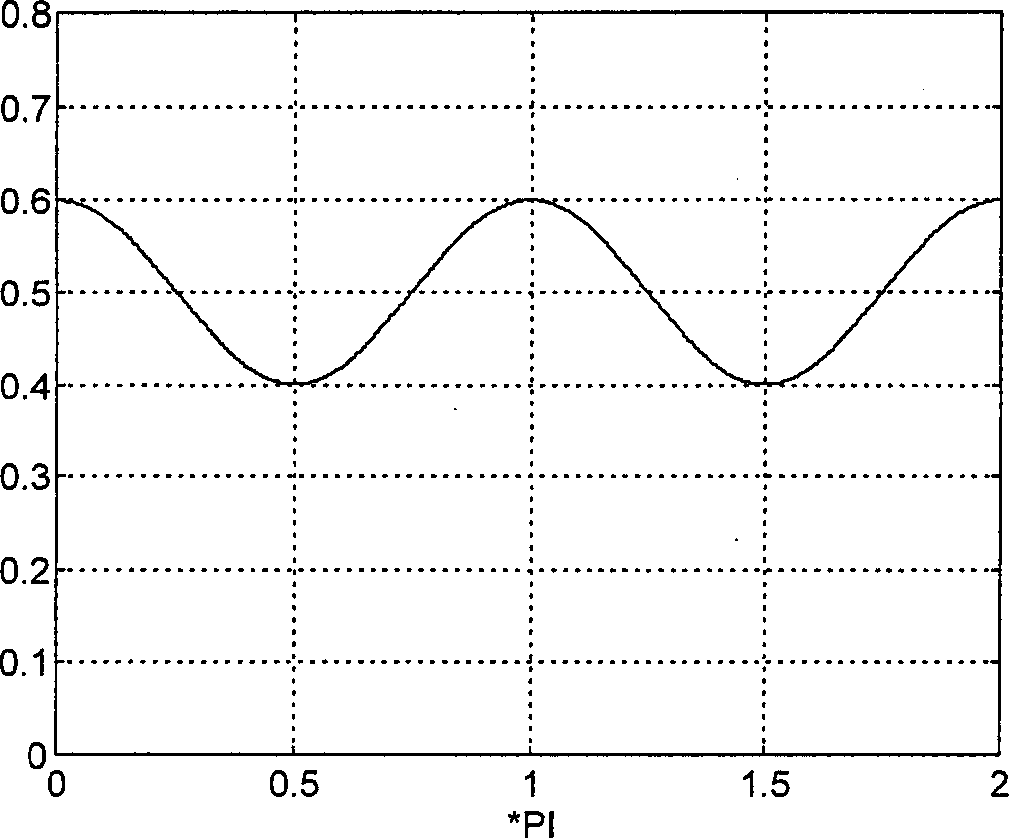

[0023] According to the present invention, start-up of open-loop vector control in a synchronous machine firstly involves determining the stator inductance model L of the synchronous machine s =L s0 +L s2 cos2θ r A step of. This equation tells how the inductance varies according to the rotor angle in the stationary frame. Thus this equation shows that when the rotor rotates by a certain angle θ r How does the inductance measured in the x-axis direction of the stator coordinate system change when ?

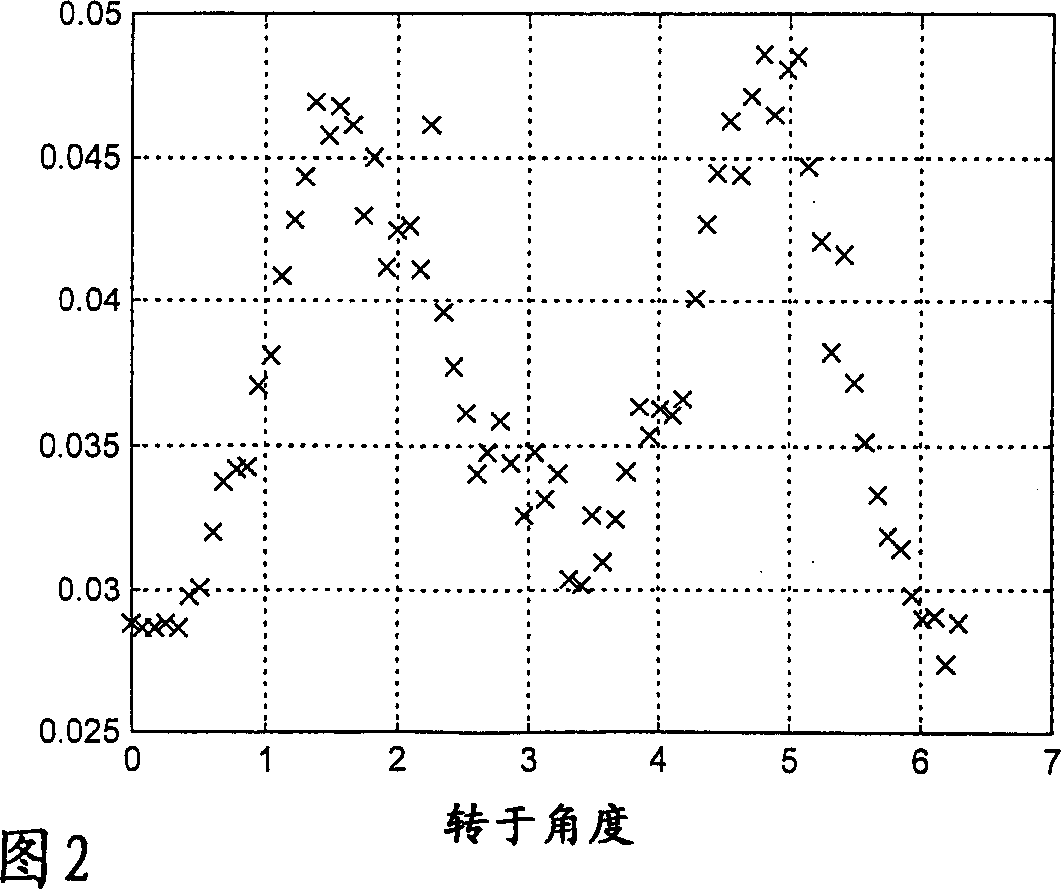

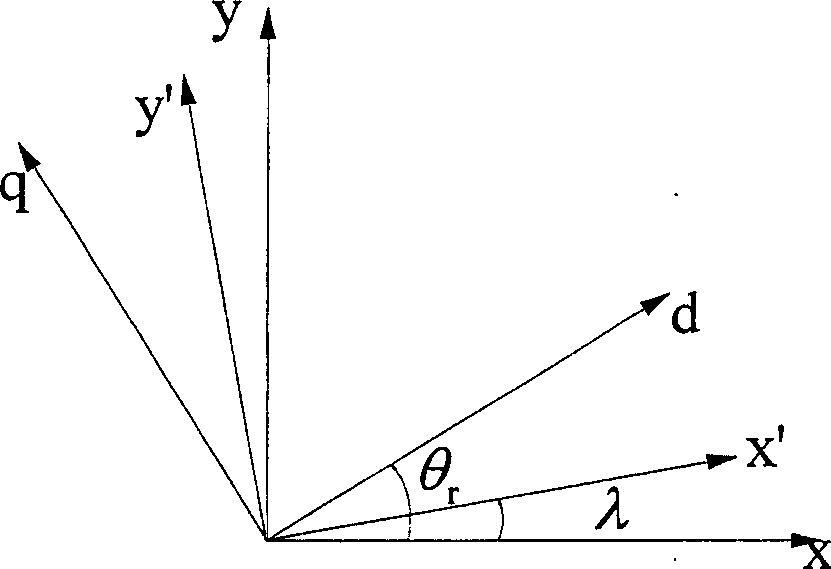

[0024] When it is desired to determine the initial rotor angle, it is not possible to rotate at different rotor azimuths to measure inductance. Instead, the stator coordinate system is rotated to an angle, and the inductance is measured in this direction. These rotatable stator frames are called virtual stator frames. image 3 Various coordinate systems are shown, and it is noted that the stator coordinate system is the coordinate system xy, the virtual stator coordinate sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com