Lead-in hot air horizohntal rotary cylinder continuous frying apparatus

A cylindrical and horizontal technology, which is applied in the field of continuous and effective frying equipment, can solve the problems of easy steam generation, difficult hot air temperature control, and large heat load, so as to promote heating and evaporation, improve processing capacity, and reduce burnt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

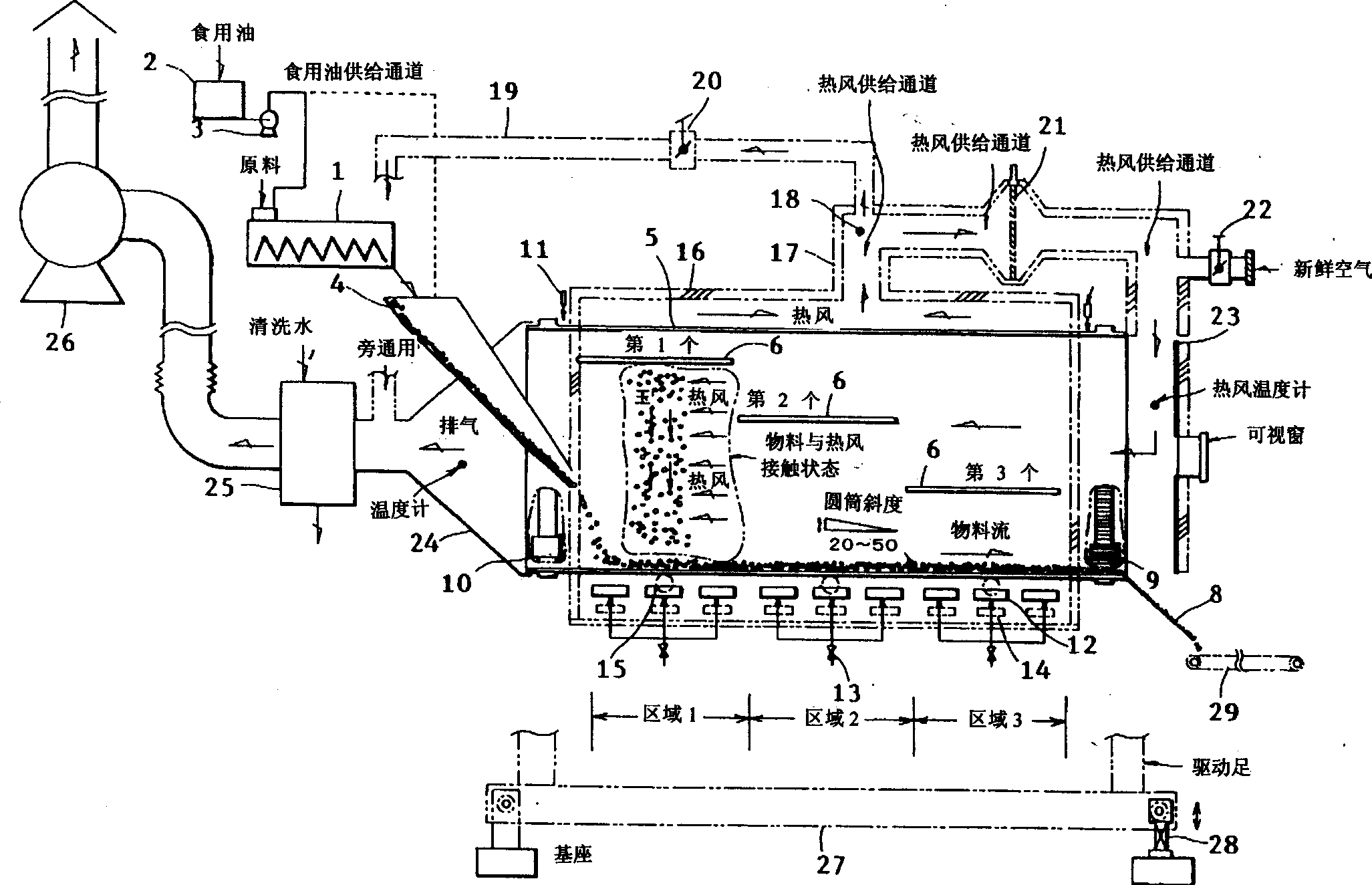

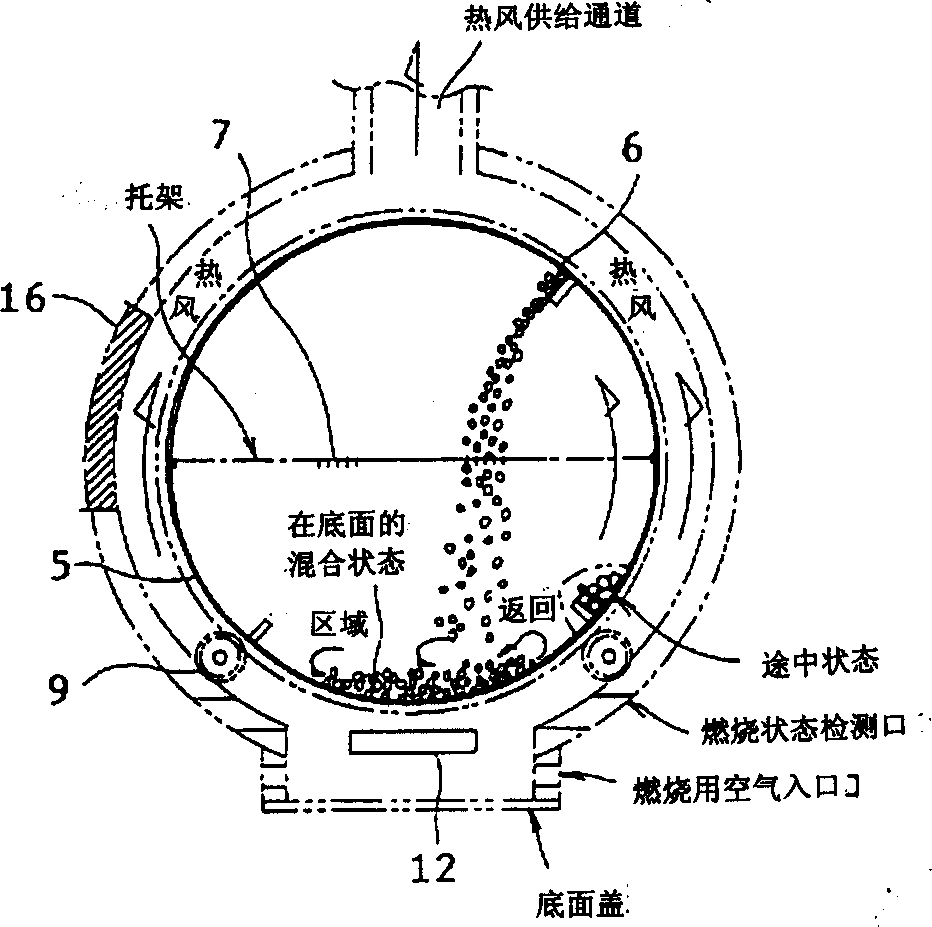

[0041] The present invention has been specifically described based on the drawings shown in the embodiments, and a part of the specific conditions and the like of the devices described above have been omitted. However, the present invention is not limited thereto.

[0042] The processed material is mixed with the edible oil used in the quantitative feeder 1 and quantitatively dropped into the feeding tank 4 . The unilateral edible oil is directly provided to the feeding tank 4 from the quantitative feeder 1 or the edible oil supply channel by the oil supply tank 2 through the oil supply pump 3 . Material and edible oil enter the raw material input end of horizontal rotating garden drum 5 subsequently.

[0043] In the rotating cylinder 5 heated according to the predetermined temperature, the input materials are stirred up, dropped, dispersed, contacted with the inner wall of the pot, mixed by the stirring blade 6, and moved to the discharge end while repeating the whole proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com