Superplastic diffusion process for joining different alloys and its application

A diffusion joining and alloying technology, applied in metal material coating process, metal processing equipment, manufacturing tools, etc., can solve the problems of low temperature, short-term and simplified process environment, and difficulty in connection effect that cannot be used for superplastic diffusion connection. The effect of shortening the time required for joining, high alloy joining quality, and lowering joining temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Connection of Ti alloy and γ-TiAl based alloy

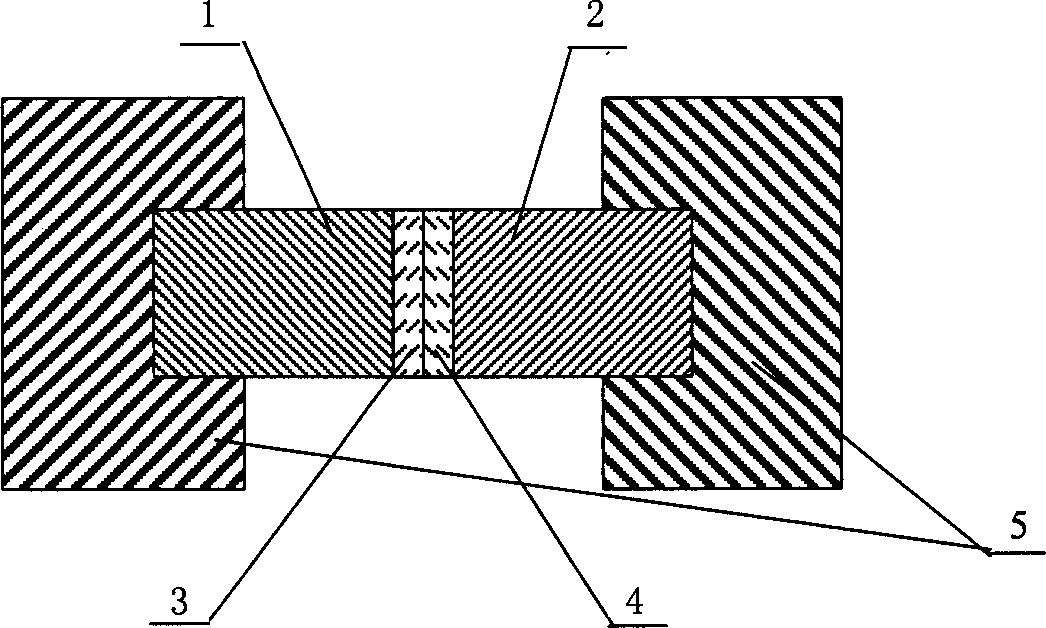

[0019] Such as figure 1 As shown, 1 is an alloy sample that exhibits superplastic potential at a lower temperature—Ti alloy (Ti-6Al-4V), and 2 is an alloy sample that only exhibits superplastic potential at a higher temperature——γ- TiAl-based alloy (Ti-47Al). The Ti alloy and the γ-TiAl-based alloy are processed into a cuboid with a length of 25 mm, a width of 10 mm, and a height of 8 mm by wire cutting. For sample 1, 5KW high-energy CO 2 The laser beam is directly subjected to laser surface rapid melting treatment, and the laser processing parameters are: output power P=2.0KW, scanning speed V=10mm / s, spot diameter a=3mm; the purity of sample 2 is 99.7%, and the particle size is 200 Purpose Titanium powder is used as an alloying powder, coated on the surface of sample 2 to be connected, and the laser treatment process is adopted while coating: the powder is fed by argon to prevent the powder from being oxidi...

Embodiment 2

[0020] Example 2: Connection of γ-TiAl-based alloy and heat-resistant steel

[0021] The γ-TiAl-based alloy sample is directly subjected to laser surface rapid melting treatment by conventional technology; the γ-TiAl-based alloy powder is selected as the alloying powder and coated on the surface of the heat-resistant steel to be connected, and the coating process uses argon Air-feeding powder to prevent oxidation of the powder during laser processing, while utilizing high-energy CO 2 The laser beam performs laser surface alloying treatment on the surface of the heat-resistant steel coated with alloying powder. By controlling the parameters of the laser processing process, an alloy layer of about 1 mm is formed on the surface of the heat-resistant steel. Under the condition of 900°C, the connection pressure of 40MPa is applied on the thermal simulator, and the connection between the γ-TiAl-based alloy and the heat-resistant steel is realized within 0.8 hours.

Embodiment 3

[0022] Example 3: Connection of γ-TiAl-based alloy and nickel-based alloy

[0023] The γ-TiAl-based alloy sample is directly subjected to laser surface rapid melting treatment by conventional technology; the γ-TiAl-based alloy powder is selected as the alloying powder, and it is coated on the surface of the nickel-based alloy to be connected. During the coating process, argon Air-feeding powder to prevent oxidation of the powder during laser processing, while utilizing high-energy CO 2 The laser beam performs laser surface alloying treatment on the surface of the nickel-based alloy coated with the alloying powder. By controlling the laser processing parameters, an alloy layer of about 1mm is formed on the surface of the nickel-based alloy. Under the condition of 900°C, the connection pressure of 40 MPa is applied on the thermal simulator, and the connection between the γ-TiAl-based alloy and the nickel-based alloy is realized within 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com