Combined paper-making machine

A paper machine and combined technology, applied in the field of paper manufacturing equipment, can solve the problems of capacitor energy consumption affecting the service life of electrolytic capacitors, unable to meet the requirements of serialization of capacitors, and unable to meet process requirements, etc., to achieve easy operation and good absorption , good strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

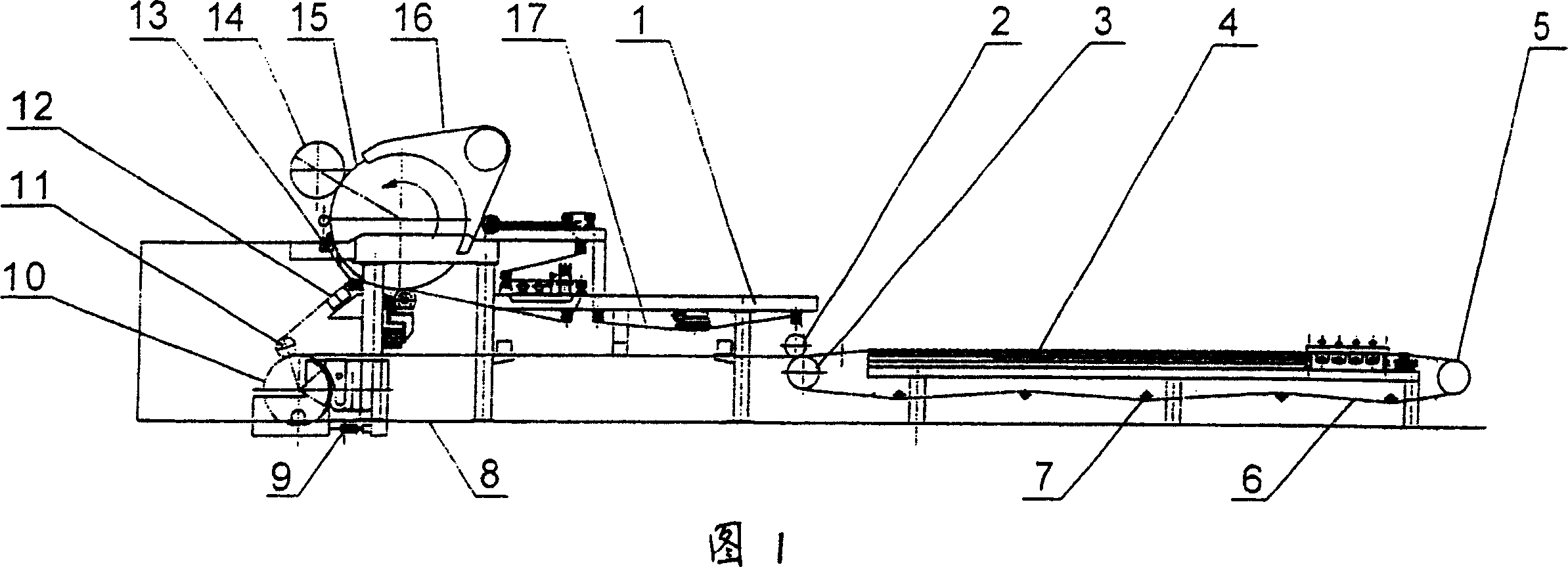

Embodiment 1

[0013] As shown in Figure 1, a combined paper machine includes a support 1, which is arranged on the bottom rail 8 of the paper machine and can slide according to specific combination needs. The support 1 is provided with a transfer roll 2 and a compound roll 11, and a transmission belt is arranged outside the transfer roll 2, the compound roll 11 and the water suction box 12. In this embodiment, the transmission belt here is selected to be able to bond the pulp fibers. The blanket 17 on it. The two ends of the side wave fourdrinier paper machine 4 are provided with a table roll 3 and a return roll 5, and the table roll 3 and the return roll 5 are connected by a transmission belt to form a loop, and a roller 7 for auxiliary transmission can be set in the loop. The transmission belt is made of polyester net 6. The pulp feeding pipe 9 of the cylinder paper machine 10 is arranged at the bottom of the cylinder paper machine 10, the transfer roll 2 on the support 1 cooperates with...

Embodiment 2

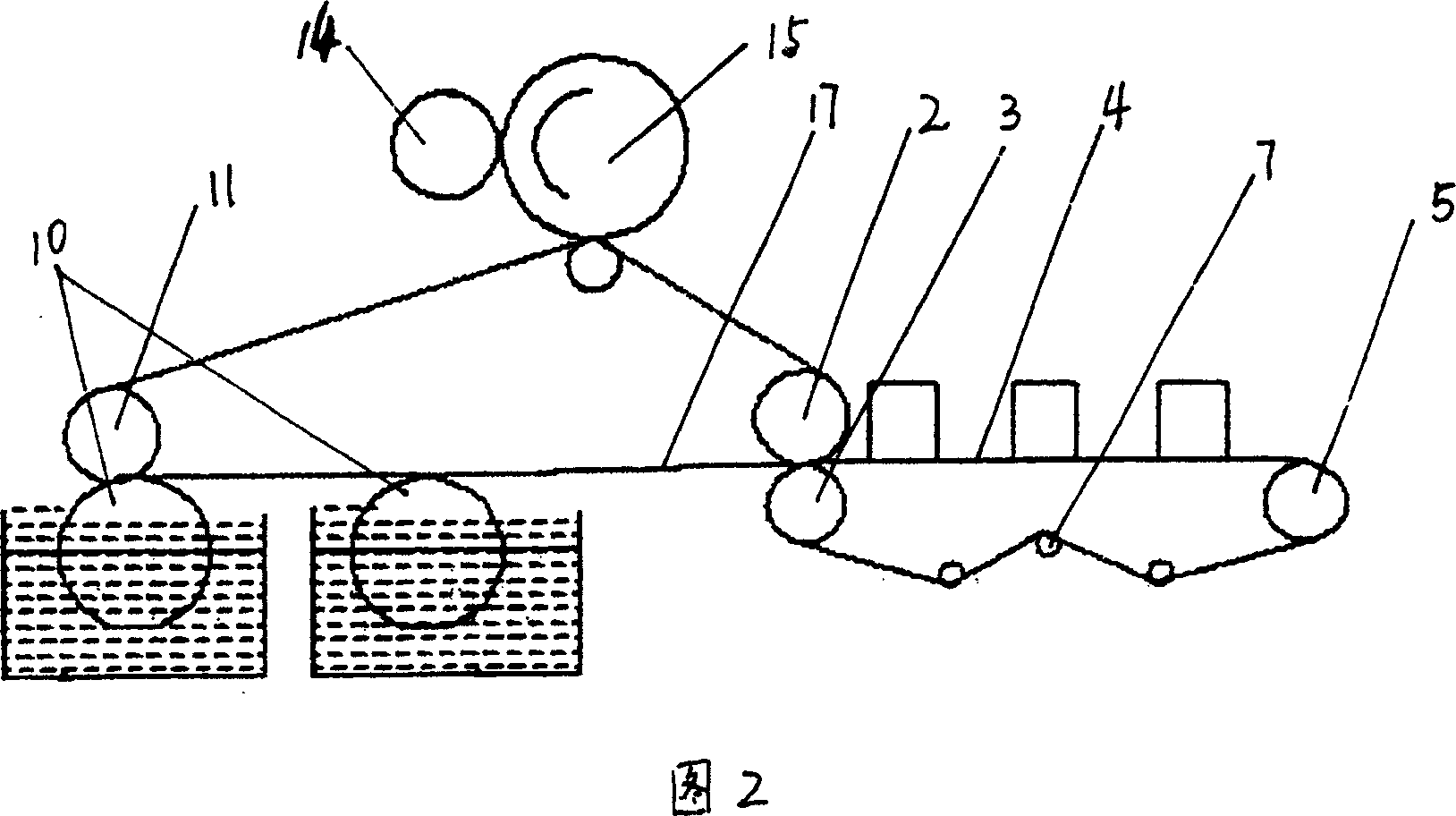

[0019] In order to solve the problem of holes in the electrolytic capacitor paper in the prior art and reduce the short-circuit rate of the capacitors made, as shown in Figure 2, one side wave Fourdrinier paper machine 4 and two rotary screen paper machines 10 can be used The combined form of papermaking to manufacture multi-layer composite electrolytic capacitor paper,

[0020] Example 1: Use the above-mentioned one-length-two-circle combined paper machine to manufacture electrolytic capacitor paper. The pulp of the pressure-resistant layer paper of the electrolytic capacitor paper is wood pulp, the beating degree is 98°SR, the wet weight is 2.8g, and the absorption layer paper is 2. Layer structure, its paper pulp uses sisal pulp and Manila hemp pulp respectively, and the degree of beating of sisal pulp is 36°SR, and the wet weight is 13.6g, and the beating degree of Manila hemp pulp is 18°SR, and the wet weight is 27.6g. The wood pulp layer is made with a side wave fourdrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com