Turbine blade and method for producing turbine blade

A technology for turbine blades and blades, applied in the fields of turbine blades and manufacturing turbine blades, can solve problems such as inability to guarantee cooling, and achieve the effects of reducing redesign time, lowering material costs, and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

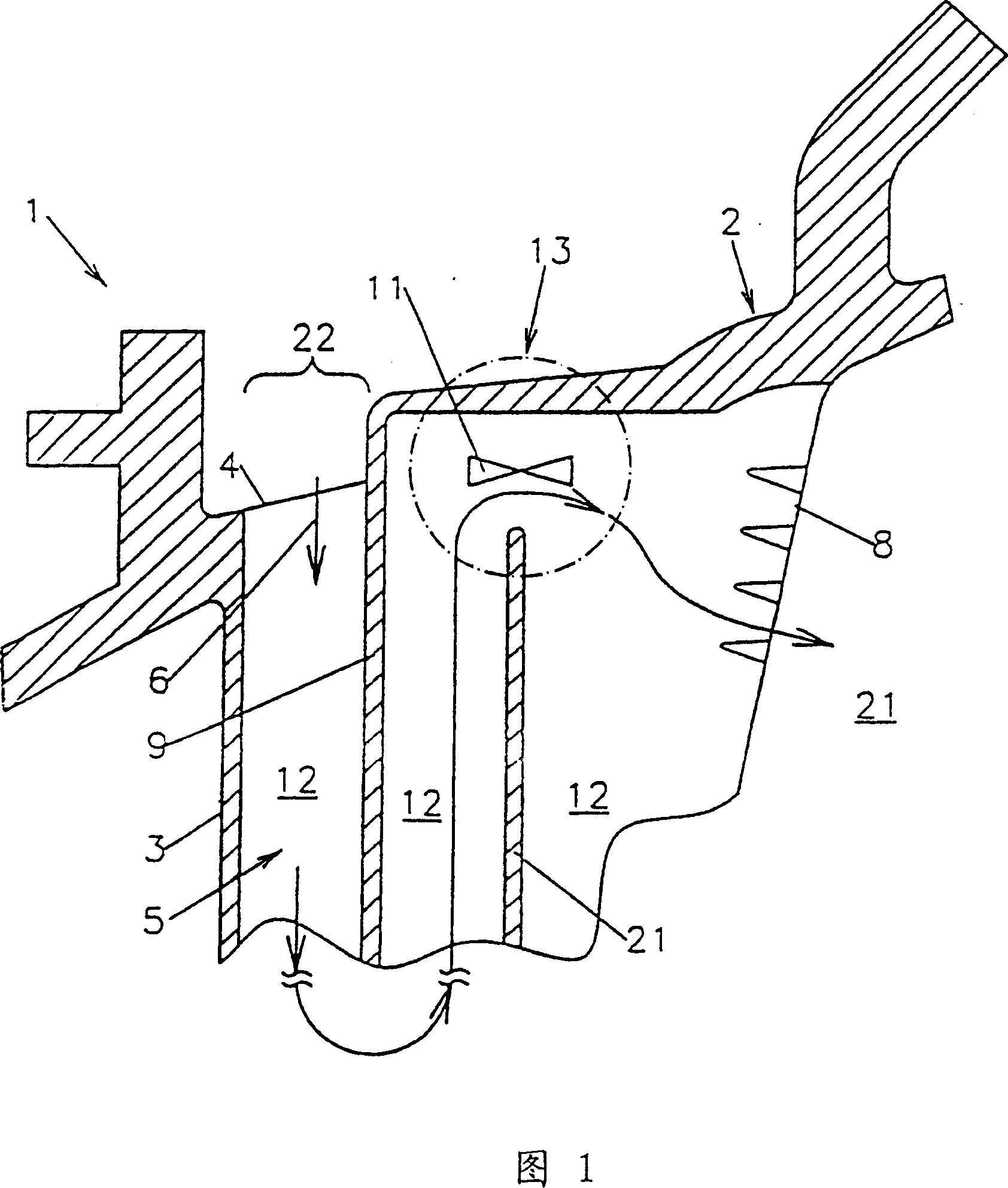

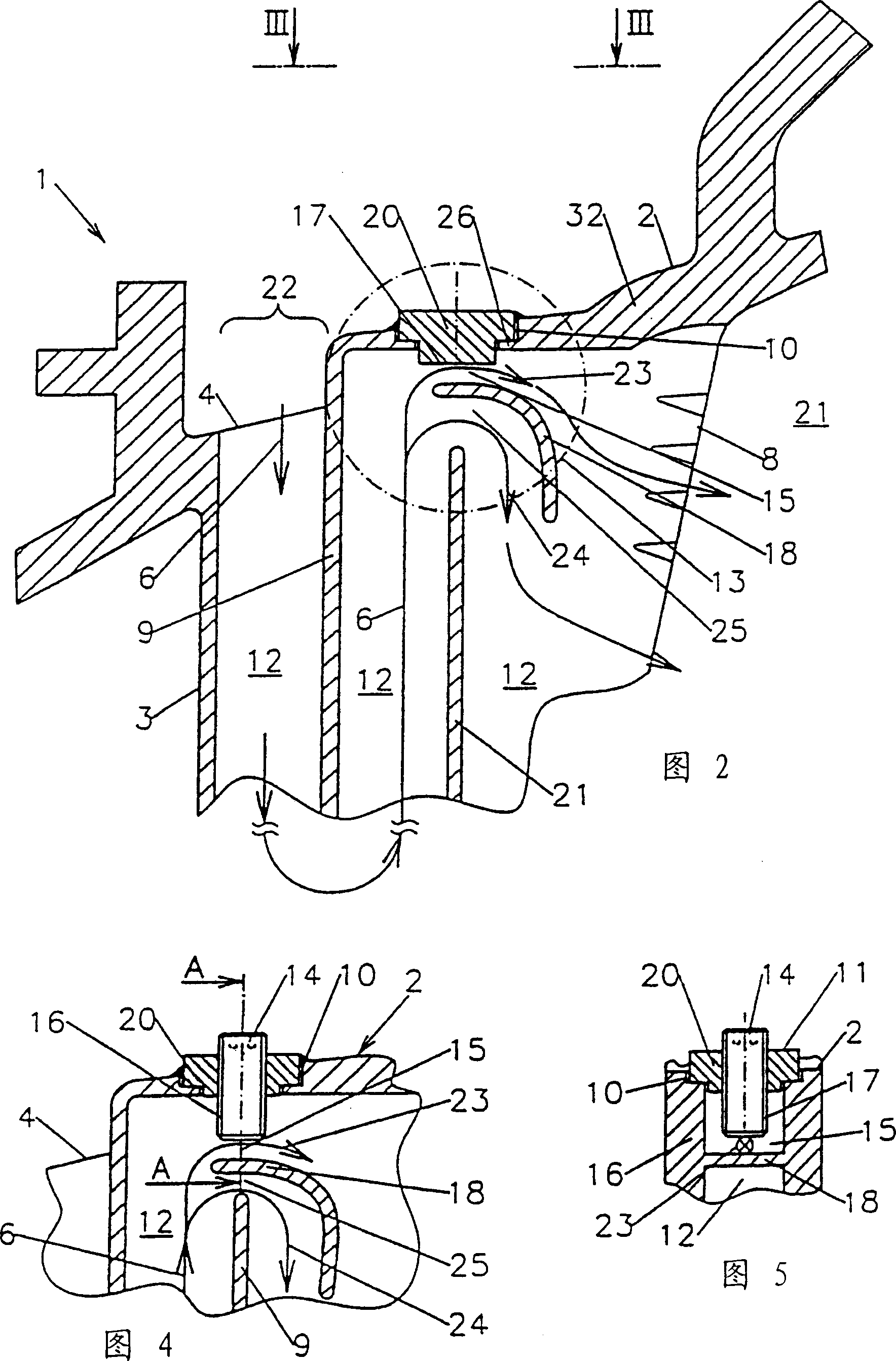

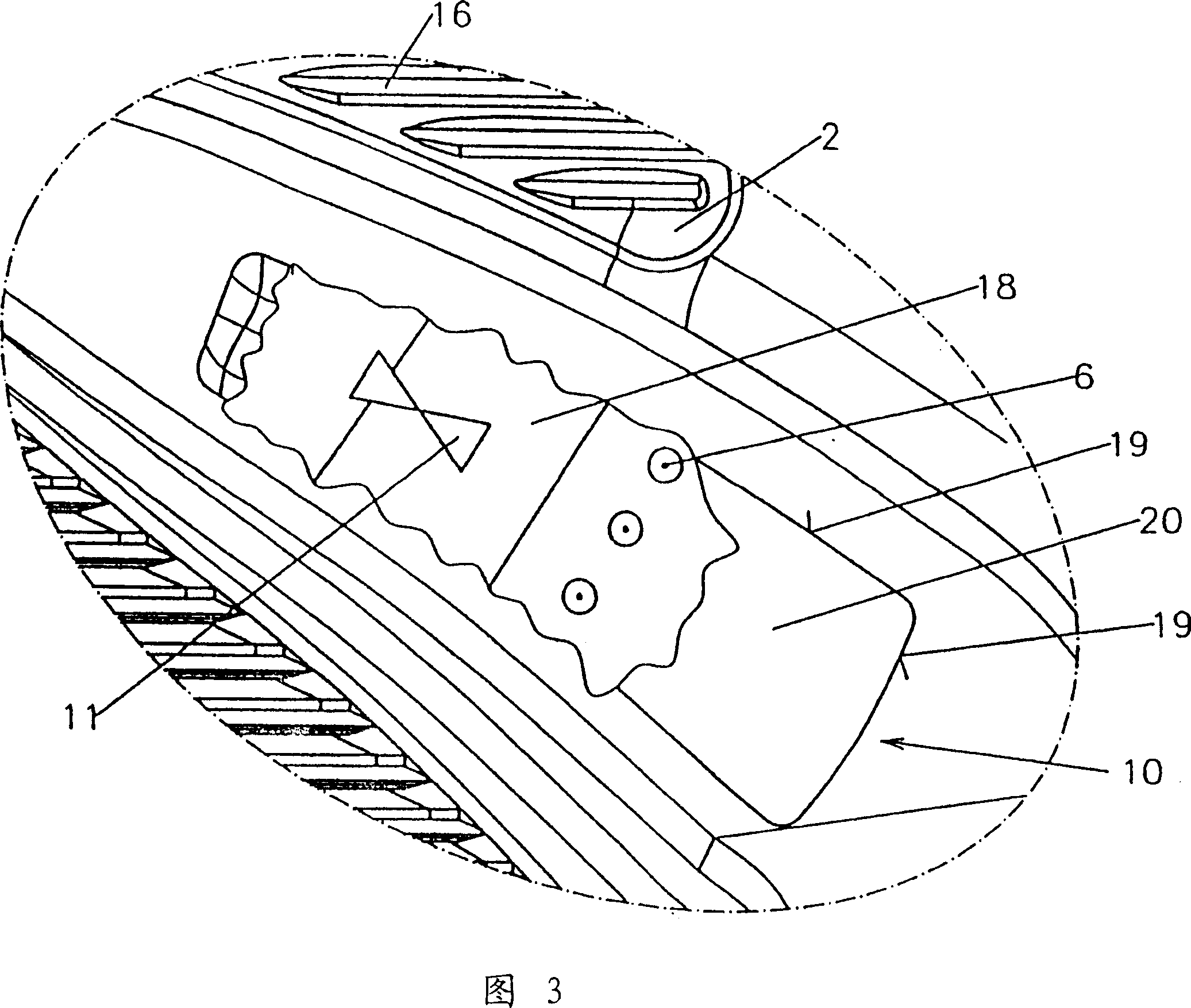

[0028] FIG. 1 shows a longitudinal section through the root region 2 and part of the channel system 5 of a gas-cooled turbine blade 1 . The channel system 5 is mainly located in the blade region 3 of the turbine blade 1 . It has an inlet hole 22 in the root region 2 at the beginning of the cooling gas flow path 6 and an outlet hole 8 in the outflow region 21 of the turbine blade 1 through which the cooling gas is introduced into the channel system 5 and through which outlet The bore 8 leaves the channel system 5 at the end of its flow path 6 . In its flow path 6 , the cooling gas is led in a meandering manner through the channels 12 separated from each other by partitions 21 , from the root region 2 to the not-shown top region and back to the root region 2 several times. These channels 12 communicate back and forth with each other through turn-back points 13 adjacent to the root zone 2 or the top zone. A throttle 11 influencing the cooling gas flow is located in the rear secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com