Multi-piece differential housings for spur gear differentials consisting of forged and sheet metal components

A differential case, cylindrical gear technology, applied in the direction of differential transmission, belt/chain/gear, transmission parts, etc., to achieve the effect of improving manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

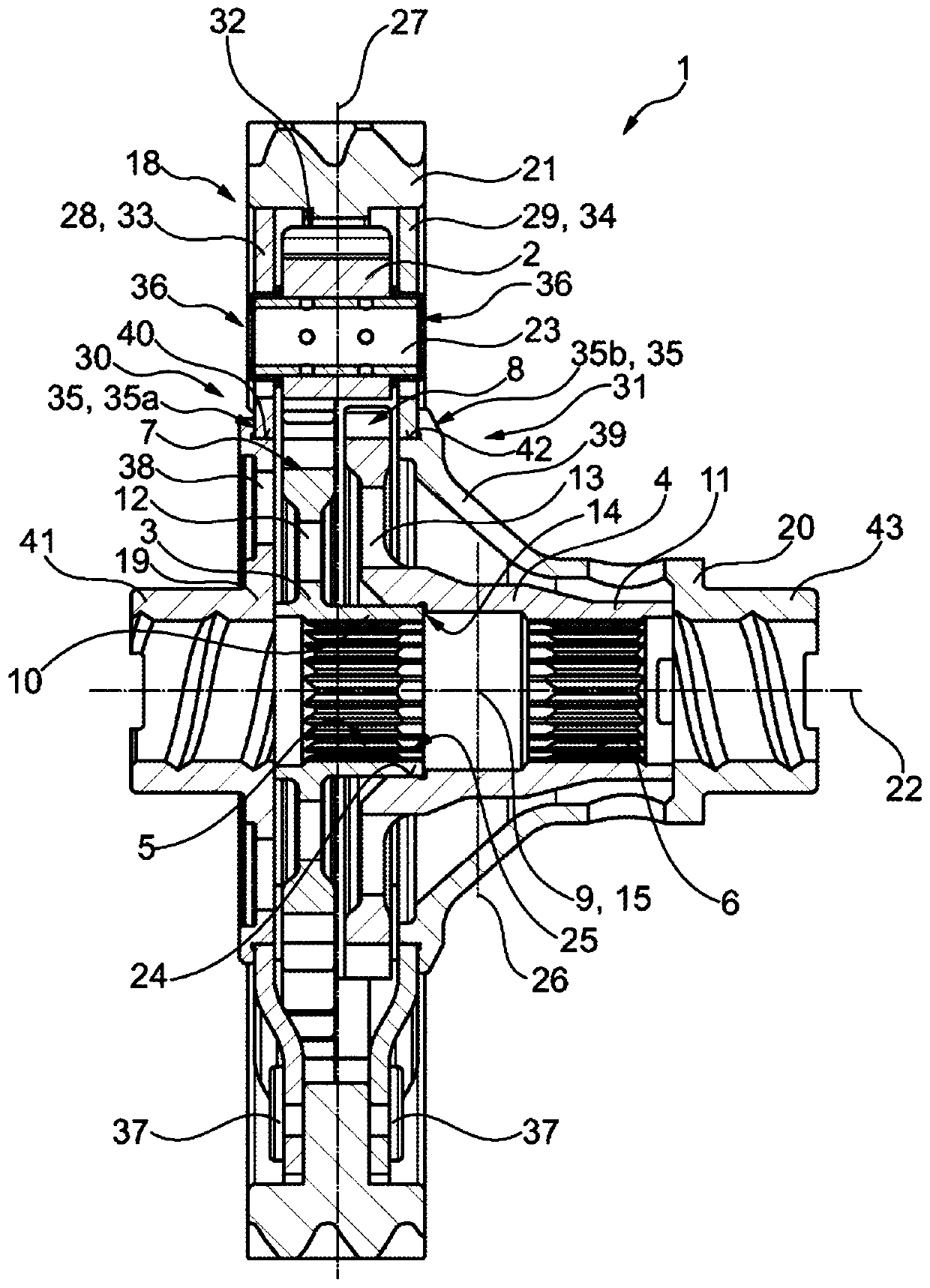

[0023] exist figure 1 In particular, the differential case 18 according to the invention according to an advantageous embodiment / an advantageous embodiment is shown intuitively, said differential case being built / installed on the spur gear differential according to the invention 1 in the state. In this case, the spur gear differential 1 is provided for use in a motor vehicle and has a drive spur gear 21 on the input side. The drive spur gear 21 meshes with a gear of the transmission output shaft in the operating state of the spur gear differential 1 in which the spur gear differential 1 is installed in the drive train of the motor vehicle, said gear being in This is not shown for clarity. The output side of the spur gear differential 1 is formed by the two sun gears 3 and 4 of the spur gear differential 1 which are designed in principle in the manner of a planetary gear, wherein each sun gear 3 , 4 is connected to a wheel of the motor vehicle. The drive shaft / output shaft a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com