Axially sliding connection brush appliance, its mfg. method and dynamo set with same brush

一种电刷装置、轴向滑动的技术,应用在机电装置、连接、控制机械能等方向,能够解决电刷减振器构件尺寸大、电刷弹性体恶化接触压力、不能减振器安装等问题,达到滑动连接位置状况好、优良减振效果、好接触稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

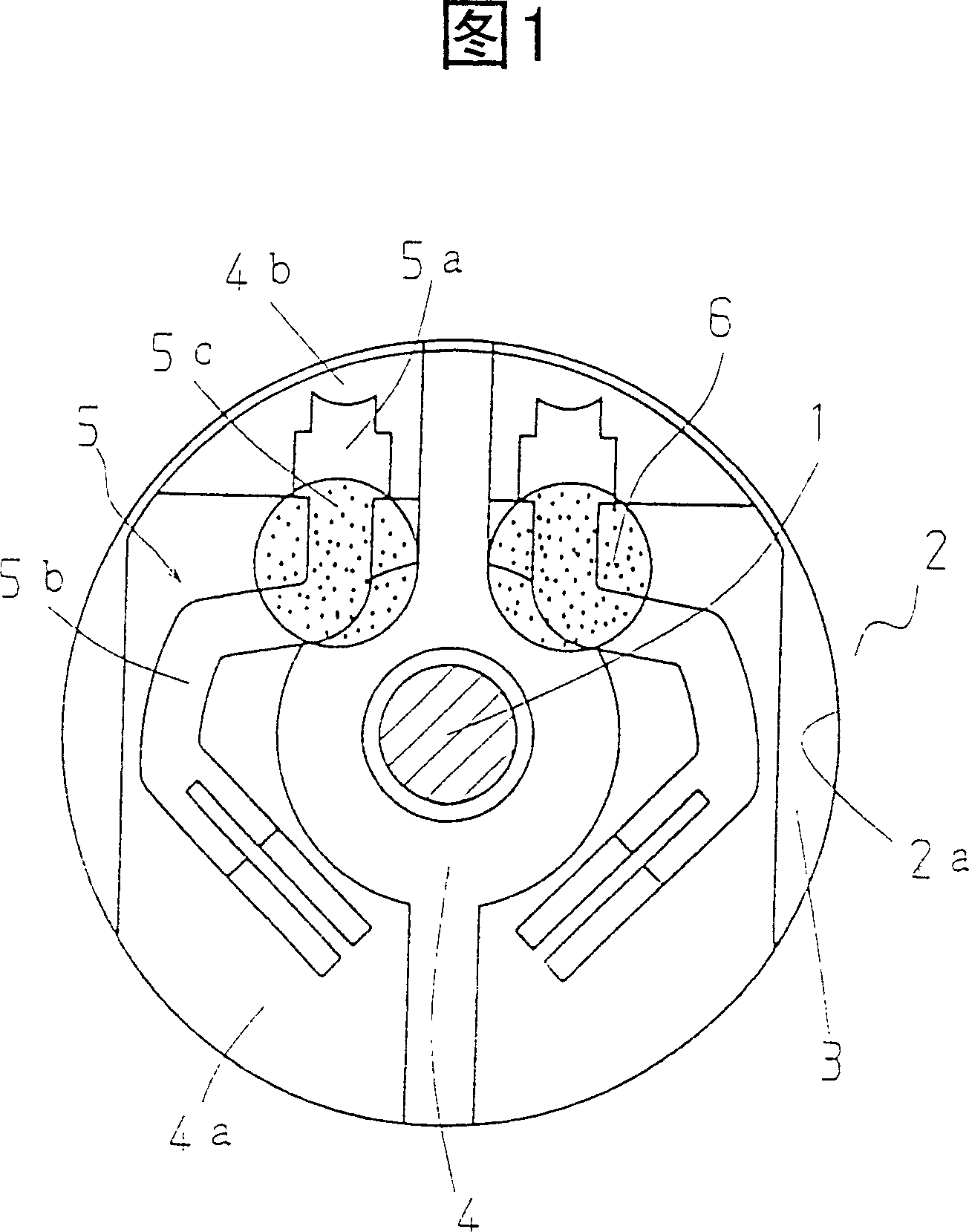

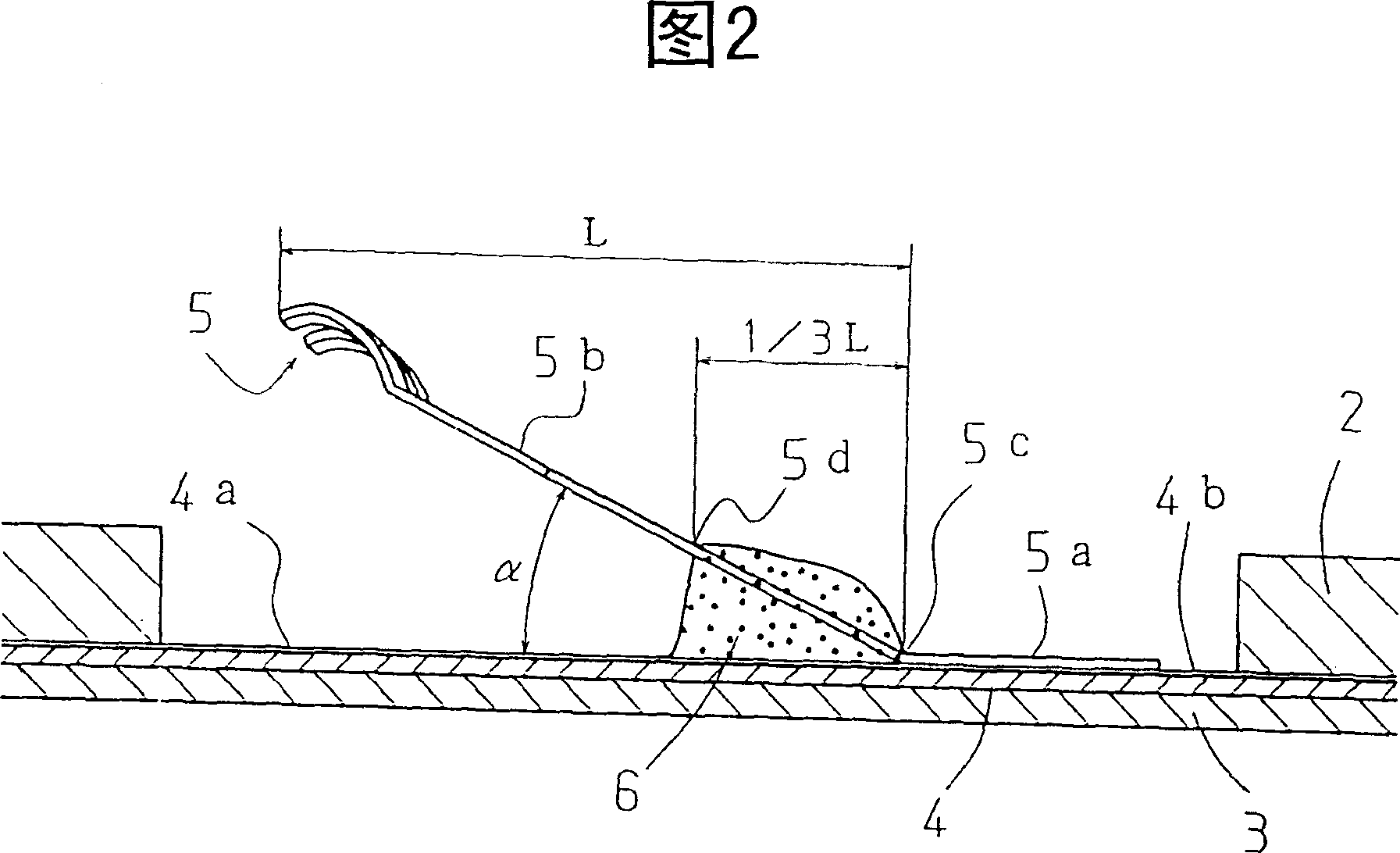

[0029] Fig. 1 is a top view of main parts showing a brush unit according to an embodiment of the present invention. In Fig. 1, the above-mentioned rotating shaft 1 is inserted through the central hole 2a of the annular stator magnet 2 fastened coaxially with the rotating shaft 1 of the motor. In the gap between the brackets 3, a brush base 4 is installed insertedly, which is fastened on one side of the bracket 3. On the exposed portion 4b of the stencil portion 4a of the brush base 4, the fastening portion 5a of the brush 5 is fastened by a method (soldering, welding, etc.) that does not affect conduction.

[0030] On the other hand, a pair of brush arms 5b are arranged symmetrically to the center of the rotating shaft 1, and the brush arms 5b have a planar curved shape in order to further increase the spring effective length of the brush arms 5b in a narrow space. Fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com