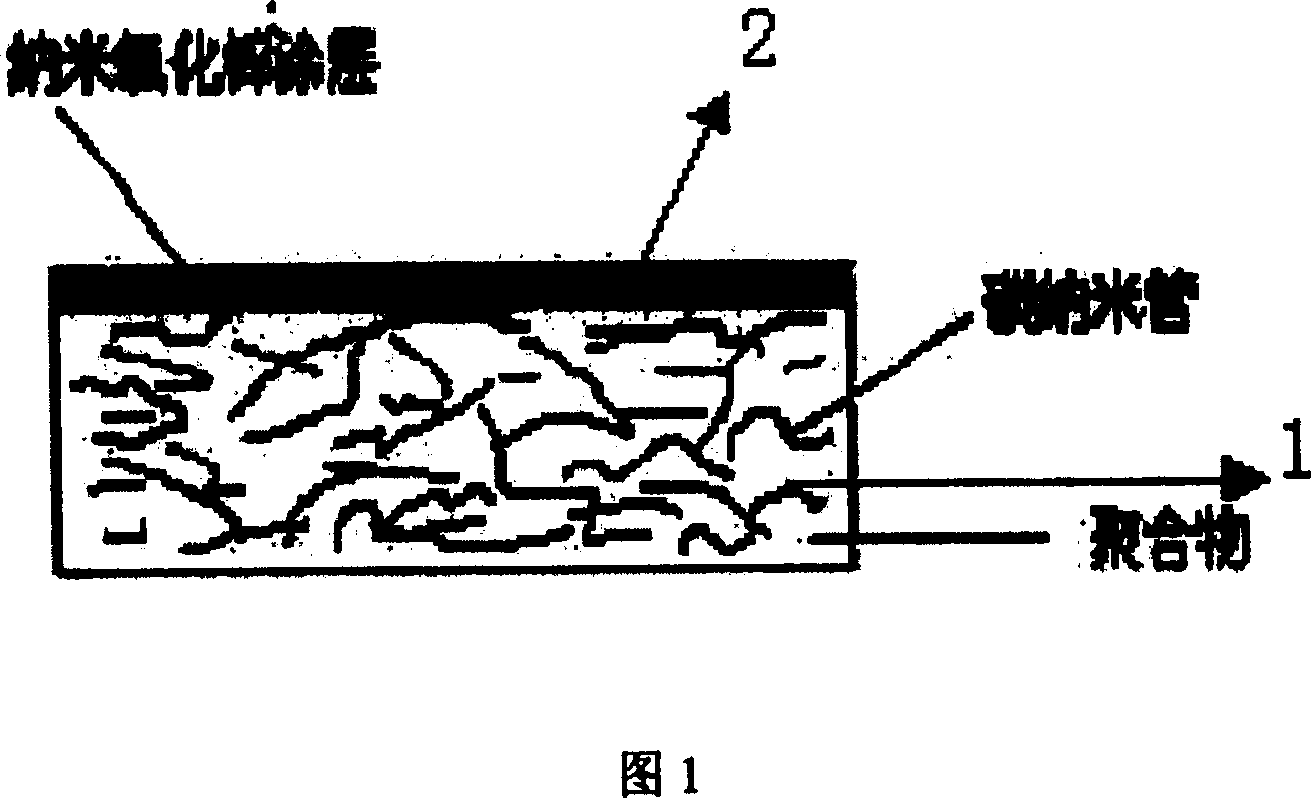

Carbon nano-pipe composite coating layer type wave absorption material and its preparation method

A technology of nanotube composite and wave-absorbing materials, which is applied in the field of composite wave-absorbing materials and their preparation, polymers containing carbon nanotubes and their coatings and their preparation, and can solve problems such as narrow frequency and small wave-absorbing peaks. Achieve excellent conductivity and reduce volume resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 1% of multi-walled carbon nanotubes with an outer diameter of 2 to 30nm and a length of 1 to 20 μm after vacuum drying, and 99% of polypropylene, first into a high-speed mixer, and then extruded through a twin-screw extruder to prepare Thin slices whose length, width and height are respectively 18mm×18mm×2mm are produced. This material exhibits a peak at 17.03GHz with a reflectivity of -1.2dB. 1% granular zinc oxide with an average particle size of 5nm and 99% varnish are formulated into a paint, and then the paint is sprayed on the surface of the above materials with a thickness of 1 μm. After the material is coated, the shape of the absorbing curve of the material is basically unchanged, but the position of the peak changes, and a peak appears at 15.90GHz, and the reflectivity is -1.1dB.

Embodiment 2

[0025] After vacuum drying, 4% of multi-walled carbon nanotubes with an outer diameter of 2 to 30 nm and a length of 1 to 50 μm and 96% of phenolic resin are first added to a high-speed mixer, and then extruded through a twin-screw extruder to prepare Thin slices whose length, width and height are respectively 18mm×18mm×2mm are produced. This material exhibits a peak at 7.6GHz with a reflectivity of -17.6dB. 50% granular zinc oxide with an average particle size of 30nm and 50% epoxy resin are formulated into a coating, and then the coating is sprayed on the surface of the above-mentioned materials with a thickness of 2 μm. After the material is coated, the shape of the absorbing curve of the material is basically unchanged, but the position of the peak changes, and a peak appears at 6.5GHz, and the reflectivity is -14.6dB.

Embodiment 3

[0027] After vacuum drying, 10% of single-walled carbon nanotubes with an outer diameter of 1-20nm and a length of 1-100μm, and 90% of EPDM rubber, are first added to a high-speed mixer, and then extruded through a twin-screw extruder. out, the length, width and height of the flakes were 18mm×18mm×2mm, respectively. This material exhibits a peak at 16.5GHz with a reflectivity of -10.2dB. 50% of rod-shaped zinc oxide with an average particle size of 100nm and 50% of varnish are formulated into a coating, and then the coating is sprayed on the surface of the above-mentioned materials with a thickness of 50 μm. After the material is coated, the shape of the absorbing curve of the material is basically unchanged, but the position of the peak changes, and a peak appears at 15.5GHz, and the reflectivity is -9.1dB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com