Acidifying, distilling and extracting method for natural propionic acid and acetic acid of propionic bacteria fermentation liquid

A technology of propionic acid bacteria fermentation liquid and distillation extraction, which is applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problem that the output cannot meet market demand, etc., and achieve low production cost and high product quality Good, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

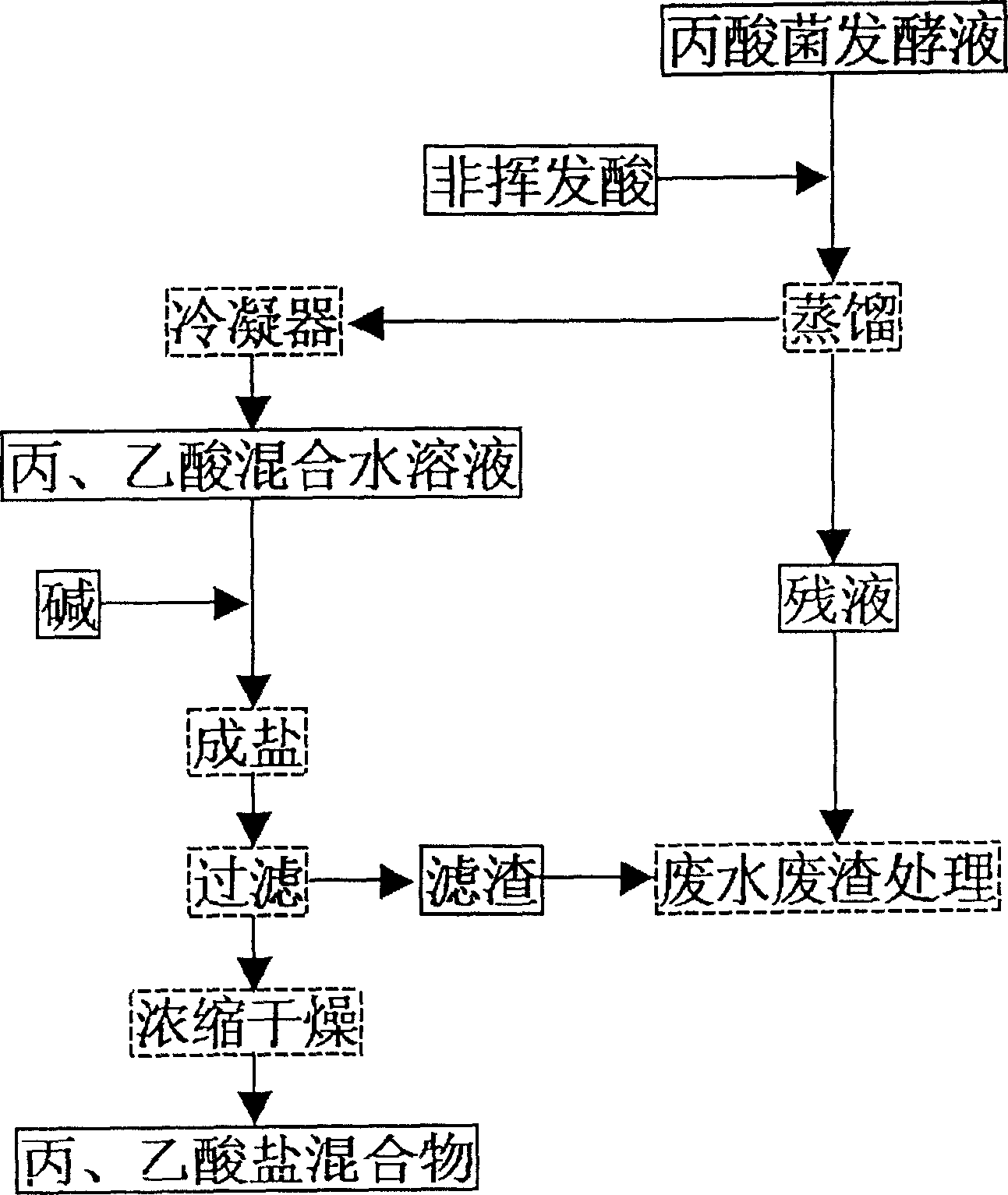

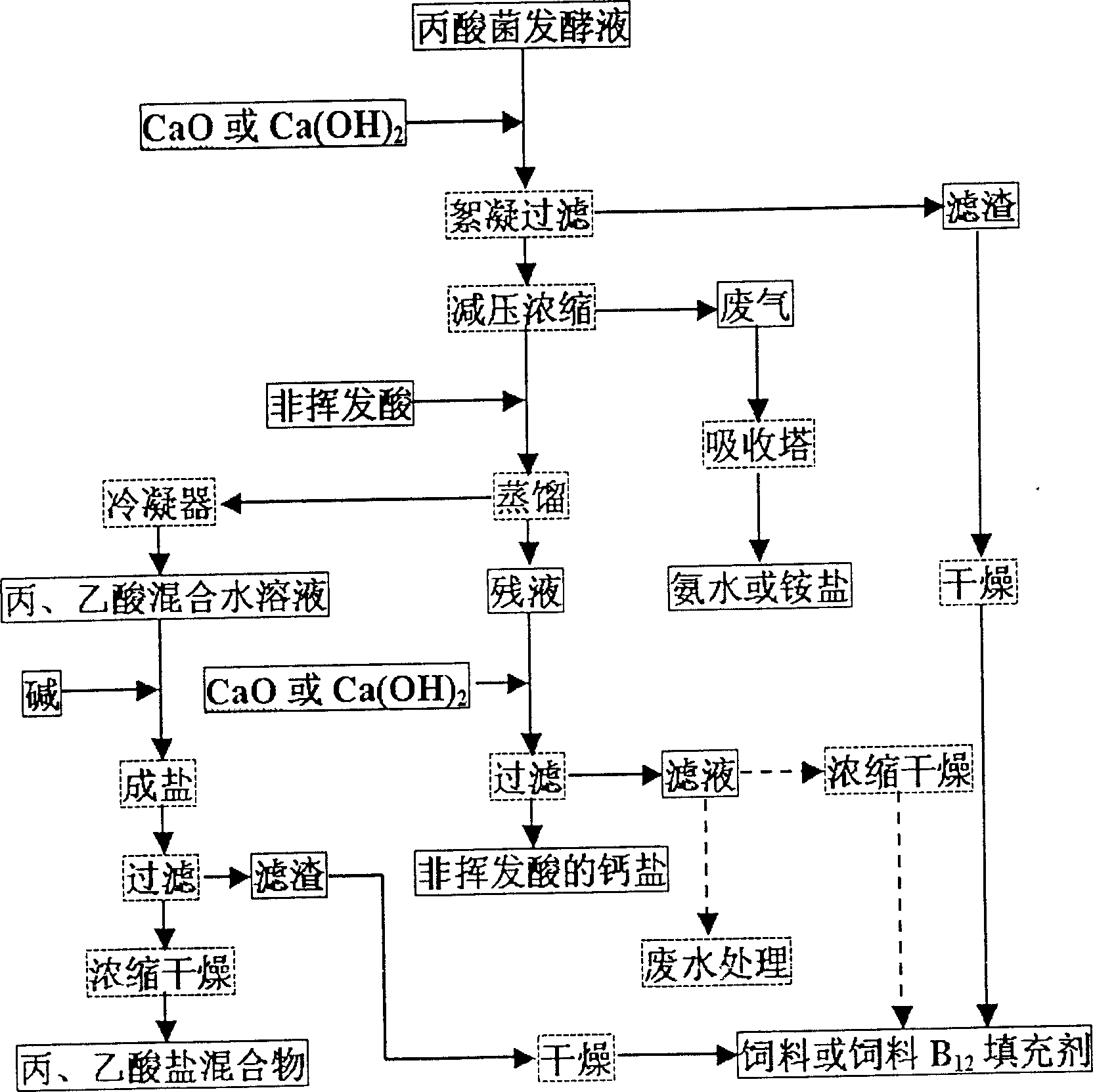

Method used

Image

Examples

specific Embodiment 1

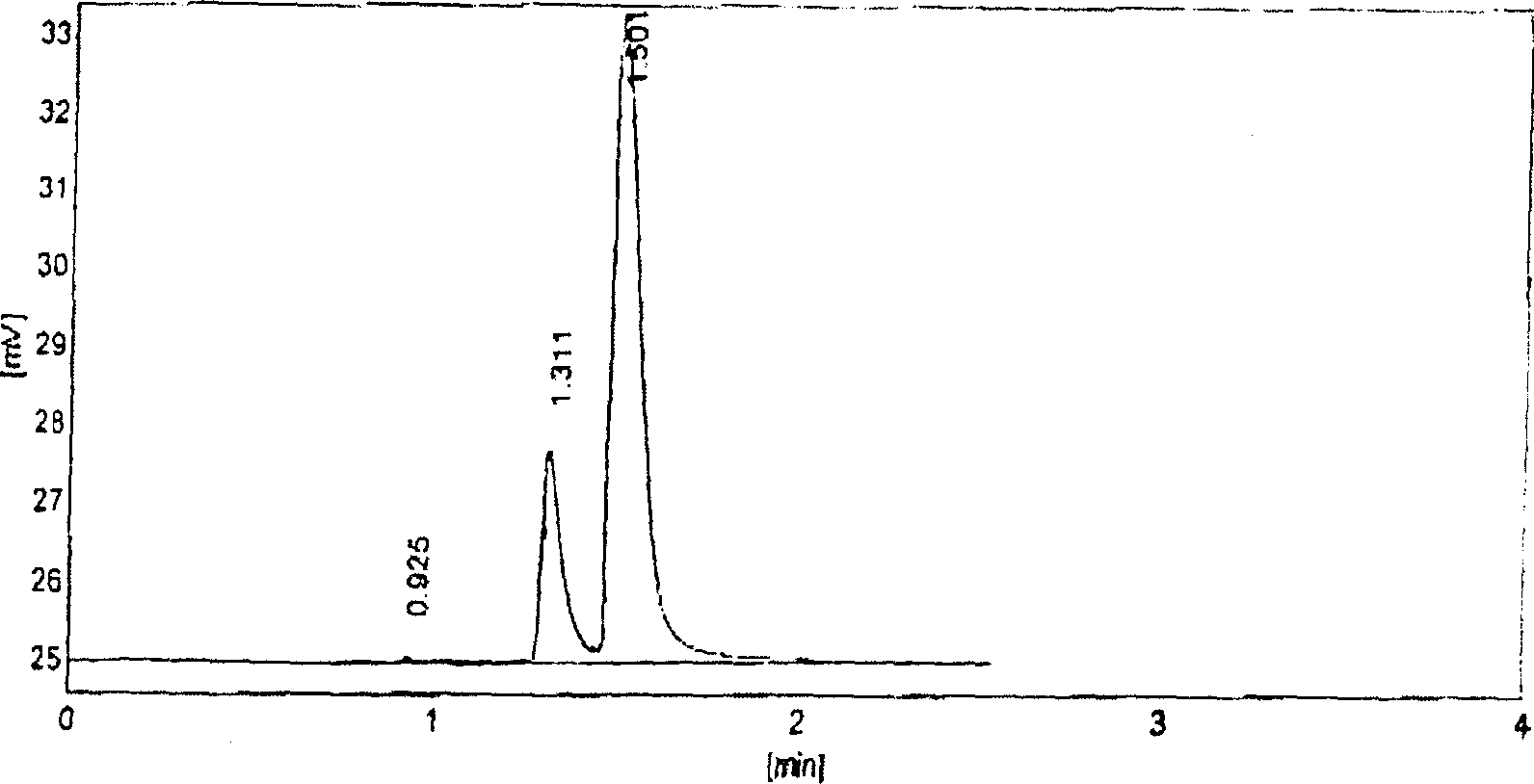

[0033] Propionic acid bacteria anaerobic fermentation of vitamin B 12 3 parts of production waste liquid, 400ml each, were adjusted to pH 3.5 with sulfuric acid, phosphoric acid and oxalic acid respectively, and after fully stirring, they were distilled under reduced pressure at 80°C, and the distillate was collected, and the total acidity was titrated with standard NaOH solution, and separated and determined by gas chromatography. , the content of acetic acid, the results are listed in Table 1.

[0034] Table 1 compares the mixed aqueous solution of propylene and acetic acid steamed out after acidifying with different acids

[0035] fermented liquid

[0036] From the above results, it can be seen that the acidity and yield of the mixed solution of propylene and acetic acid distilled from the direct acidification of the fermentation broth are relatively low, and the yield is directly proportional to the distilled volume.

Embodiment 2

[0038] Propionic acid bacteria anaerobic fermentation of vitamin B 12 Production waste liquid 800ml, is equally divided into four parts, with Ca(OH) 2 Adjust the pH to 8.0, 8.5, 9.0, and 9.5 in turn, filter to remove the precipitate, and concentrate the filtrate at 75-80°C to about half the volume, take it out and measure the pH, adjust the pH to 2.0 with sulfuric acid, Distill under reduced pressure to about 60% of distillate volume, measure the total acidity of distillate and measure propane, acetic acid content with gas chromatography, the results are listed in Table 2.

[0039] Fermentation filtrate (ml)

[0040] From the above results, it can be seen that the total acidity of the recovered mixture of propane and acetic acid is inversely proportional to the residual volume percentage of waste liquid concentration, and the yield is directly proportional to the volume percentage of distilled off. relation.

Embodiment 3

[0042] Take the propionic acid bacteria fermentation filtrate at pH 8.5, concentrate it under reduced pressure to about 50% of the volume, divide it into 4 parts, 80ml each, adjust pH 3.5, 3.0, 2.5 and 2.0 with sulfuric acid, and distill under reduced pressure at 70°C to distillate About 50% of the volume, measure the total acidity of the distillate and measure the content of propane and acetic acid with gas chromatography, the results are listed in table 3.

[0043] Volume of waste liquid concentrate (ml)

[0044] As can be seen from the data in Table 3, the total acidity of the propane and acetic acid mixed aqueous solution that reclaims rises with the reduction of acidification pH before distillation; rise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com