Photosensitive silver slurry for concentration electrode and method for preparing same

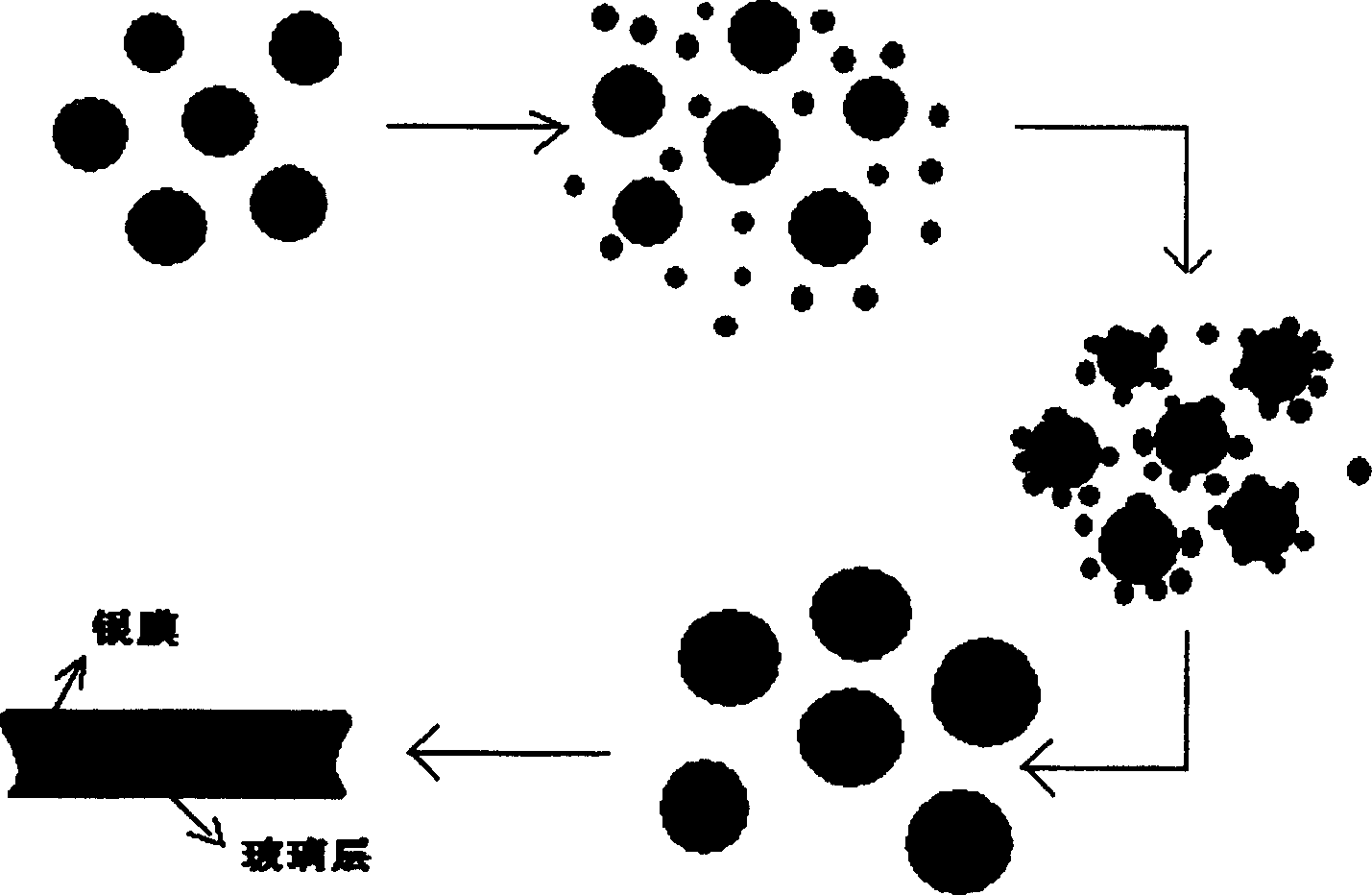

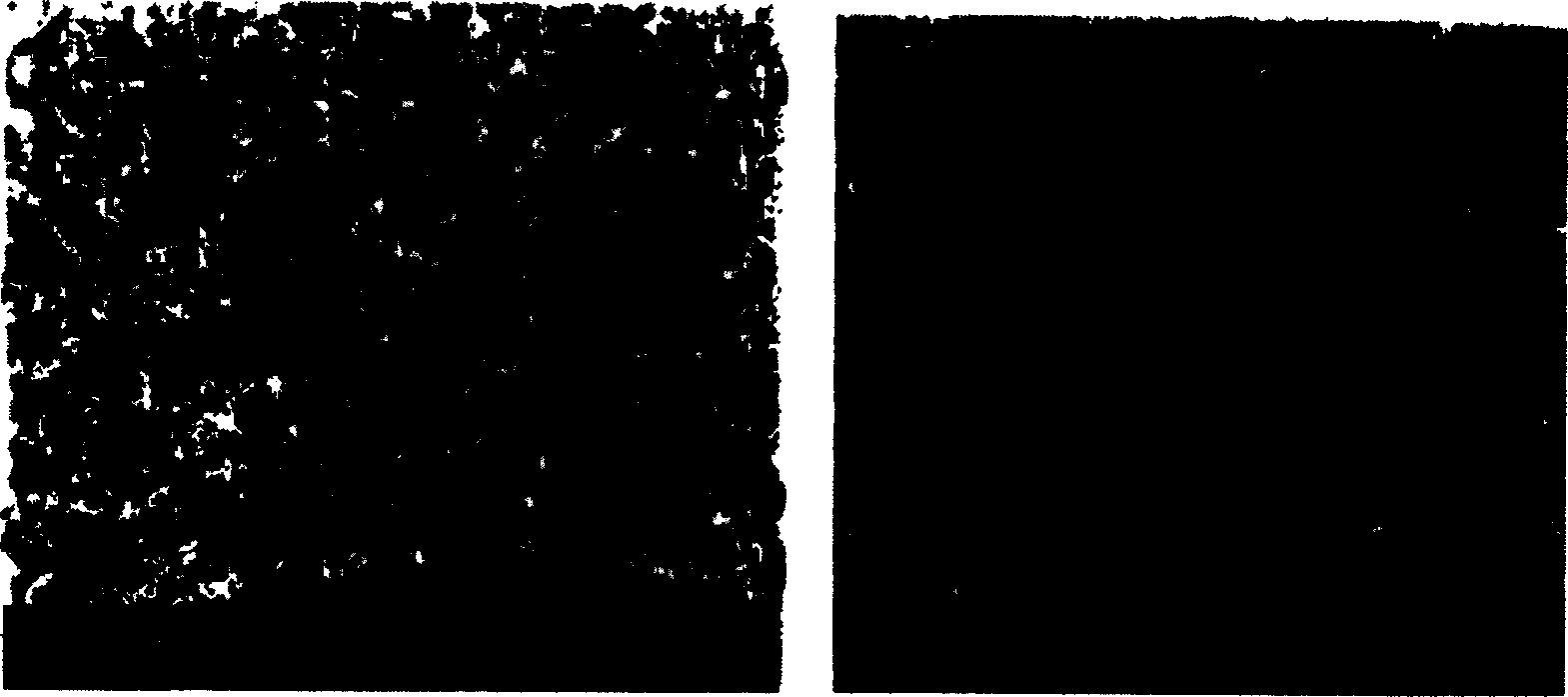

A bus electrode and photosensitive technology, applied in the field of photosensitive silver paste for bus electrode and its preparation, can solve the problems of unevenness and discontinuous silver distribution, and achieve the effect of uniform silver distribution, small shrinkage rate and continuous electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A photosensitive silver paste for a bus electrode of a plasma display, comprising silver-coated glass powder with a particle size of 0.8-1 μm, nano-silver powder, black dye, photosensitive monomer, photoinitiator, organic solvent, and cellulose Resin and plasticizer, its weight proportion is (5~20%): (40~60%): (1~20%): (3~20%): (0.3~5%): (5~20 %): (5~20%): (1~2%), the above-mentioned silver-coated glass powder is coated with silver film on the outer surface of glass powder particles, and the photosensitive monomer is acrylate or methacrylate, The photoinitiator is one of benzoin and its derivatives, acetophenone and its derivatives or aromatic ketones, the organic solvent is a polar organic solvent with a boiling point above 200°C, and the plasticizer is a polar organic solvent containing a polar ester group. ester, the particle size of the glass powder in the above silver-coated glass powder is 400-600nm, and its formula composition includes: PbO 45%-80%, SiO 2 4~20%...

Embodiment 2

[0015] A preparation method for making the above-mentioned photosensitive silver paste: first prepare silver-coated glass powder and an organic vehicle respectively, and then prepare the photosensitive silver paste. The preparation of the above-mentioned silver-coated glass powder is based on the concentration of 10~20g / L AgNO 3 Stir 125ml of the solution, and add ammonia water until a brown precipitate is formed, then add ammonia water until the precipitate is completely dissolved to obtain a silver-ammonia complex solution, and then add hydrogen with a concentration of 5 to 10 g / L in the silver-ammonia complex solution Sodium oxide solution 40ml, and then add ammonia water dropwise to make the solution transparent, the transparent solution is the silver plating solution; dissolve 40-80g of glucose and 2-20g of tartaric acid in 1000ml of distilled water in turn, boil to fully dissolve the glucose and tartaric acid , cooled to room temperature, adding 5 to 50 ml of absolute et...

Embodiment 3

[0017] Preparation of Ultrafine Glass Powder

[0018] The raw material is 65% by weight of PbO, SiO 2 11%, B 2 o 3 20%, ZnO 4% Grind in a porcelain mortar and mix well. Put this batch material into a high alumina crucible, melt at 1000°C for 2 hours, and melt into a glass state. Pour the glass liquid into cold water, dry the glass slag in a constant temperature box, and ball mill it with a planetary ball mill until the particle size is 400-600nm, then dry it for later use.

[0019] Silver-plated surface of ultra-fine glass powder

[0020] Take 10gAgNO 3 Fully dissolve in 125ml of distilled water, keep stirring the silver solution, slowly add ammonia water until a brown precipitate is formed, then add ammonia water until the precipitate is completely dissolved; add 25g of sodium hydroxide and dissolve in 100ml of distilled water to prepare a sodium hydroxide solution. Add 40ml of sodium hydroxide solution to 125ml of silver nitrate solution, and then add ammonia water d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com