Highly effective filter medium and its manufacturing method and medical protective garment manufactured by the same

A filter material and high-efficiency technology, applied in clothing, protective clothing, separation methods, etc., can solve problems such as inability to achieve, and achieve the effects of good ventilation, improved wearing comfort, fiber diameter uniformity and electrostatic adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

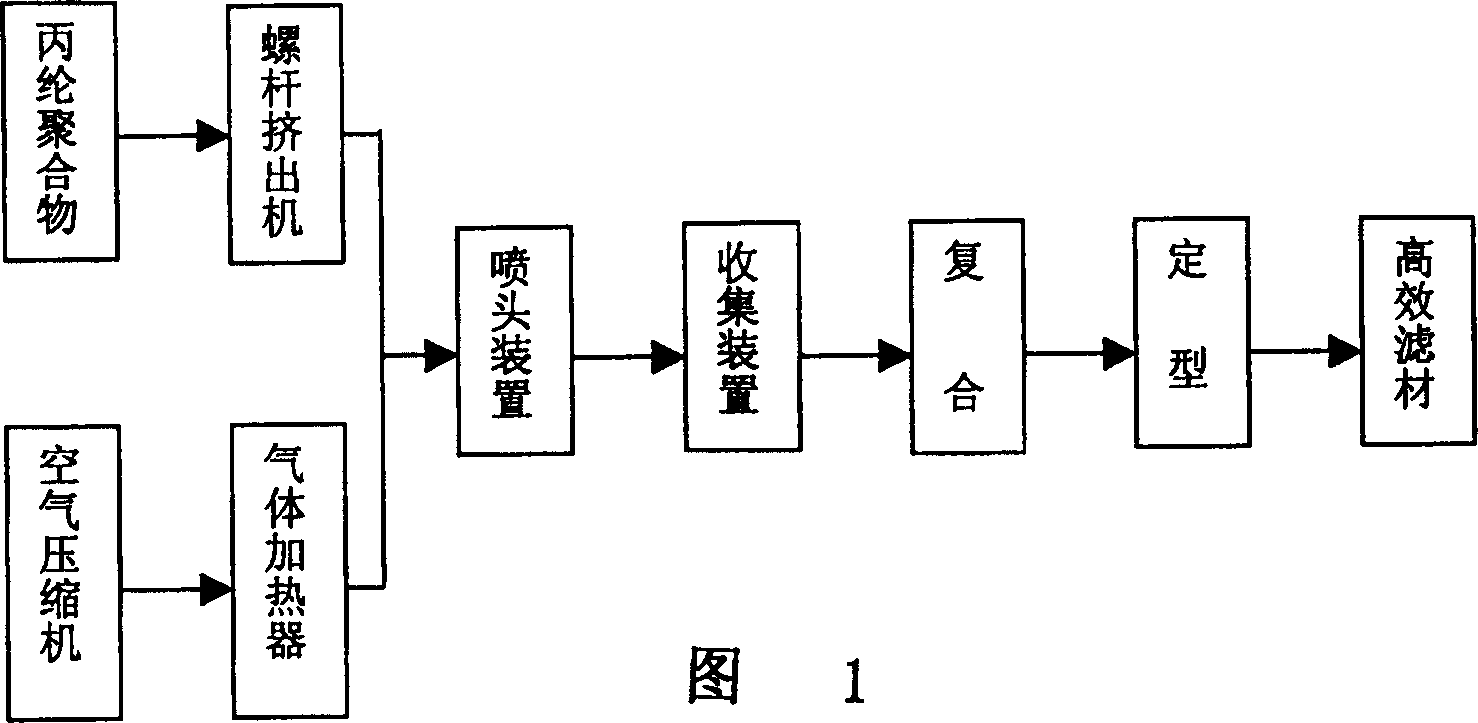

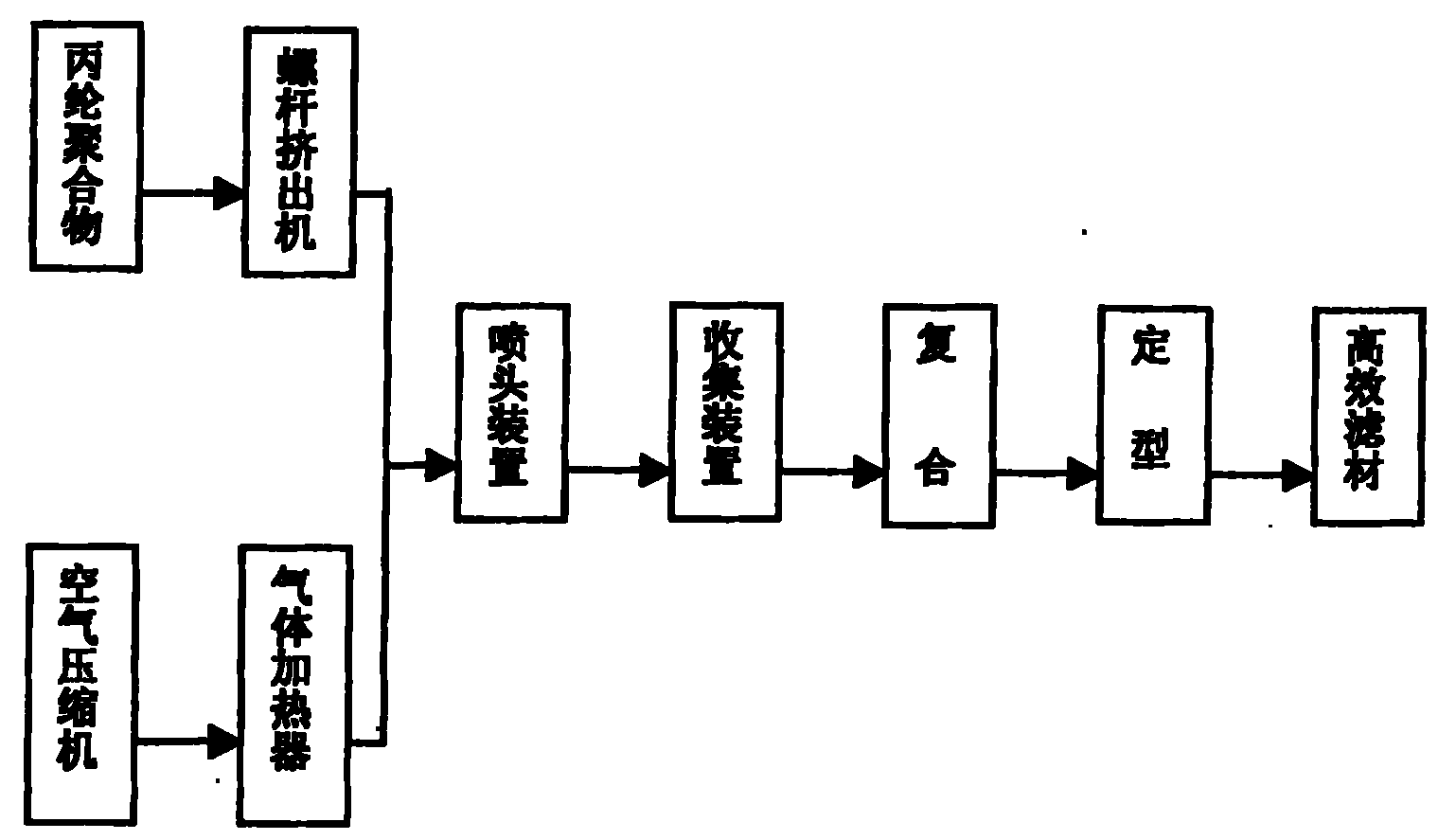

[0027] As shown in Figure 1, take a polypropylene polymer slice with a melt index of 1200MFR and put it into a screw extruder; under the condition of a metering pump speed of 60RPM, the pressure gas produced by the air compressor passes through the gas heater. Heated to 260°C; the screw extruder extrudes the molten polypropylene polymer into the spinneret in the nozzle device, draws it through the hot air with an air velocity of 550m / s, and then lays it on the collector to form fibers The fineness is less than 0.3μm, and the quantitative specification is 20-80g / m 2 Ultra-fine fiber high-efficiency filter material. At this time, the lower suction volume of the collecting device is 65%, the upper suction volume is 60%, and the cooling air output volume is 55%. The ultra-fine polypropylene fiber high-efficiency filter material and the specification of the reinforced base material are 25-30 / m 2 The polypropylene filament non-woven fabric is compounded under the conditions of pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com