Photoresist supply system and method

A supply system, photoresist technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as pattern distortion, inability to provide etching masks, etc., to avoid excessive mixing and agitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

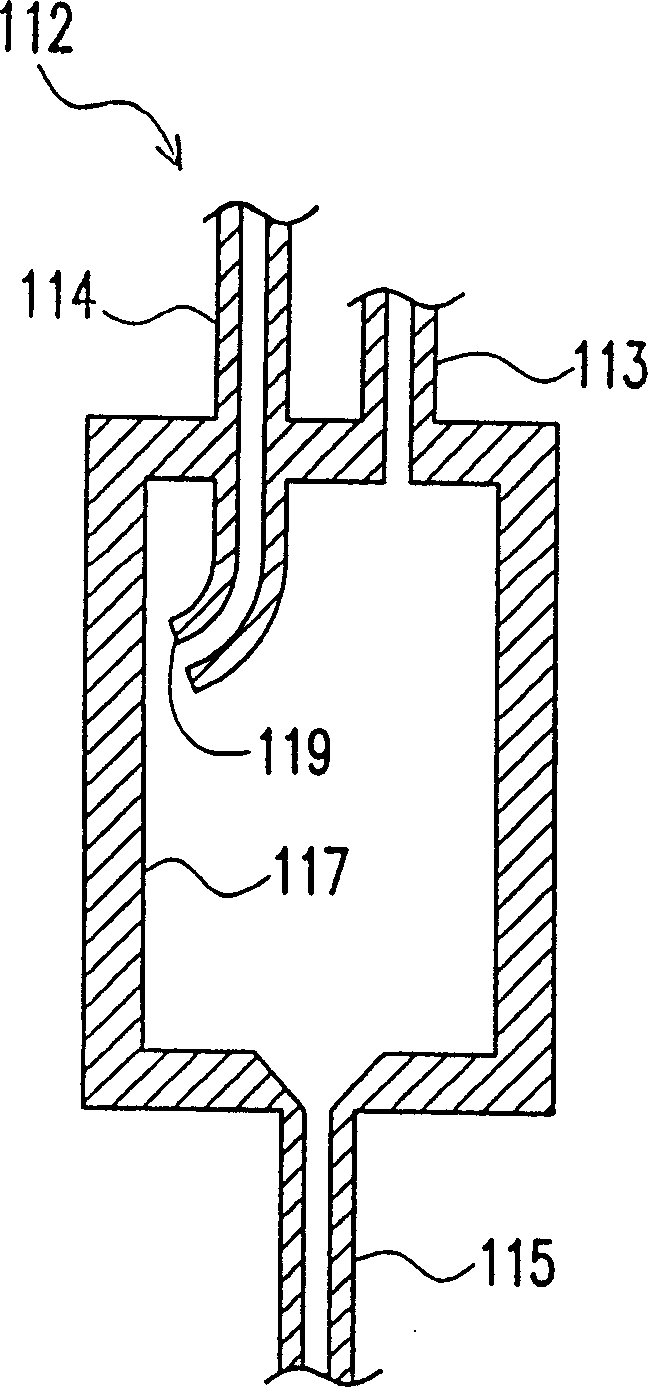

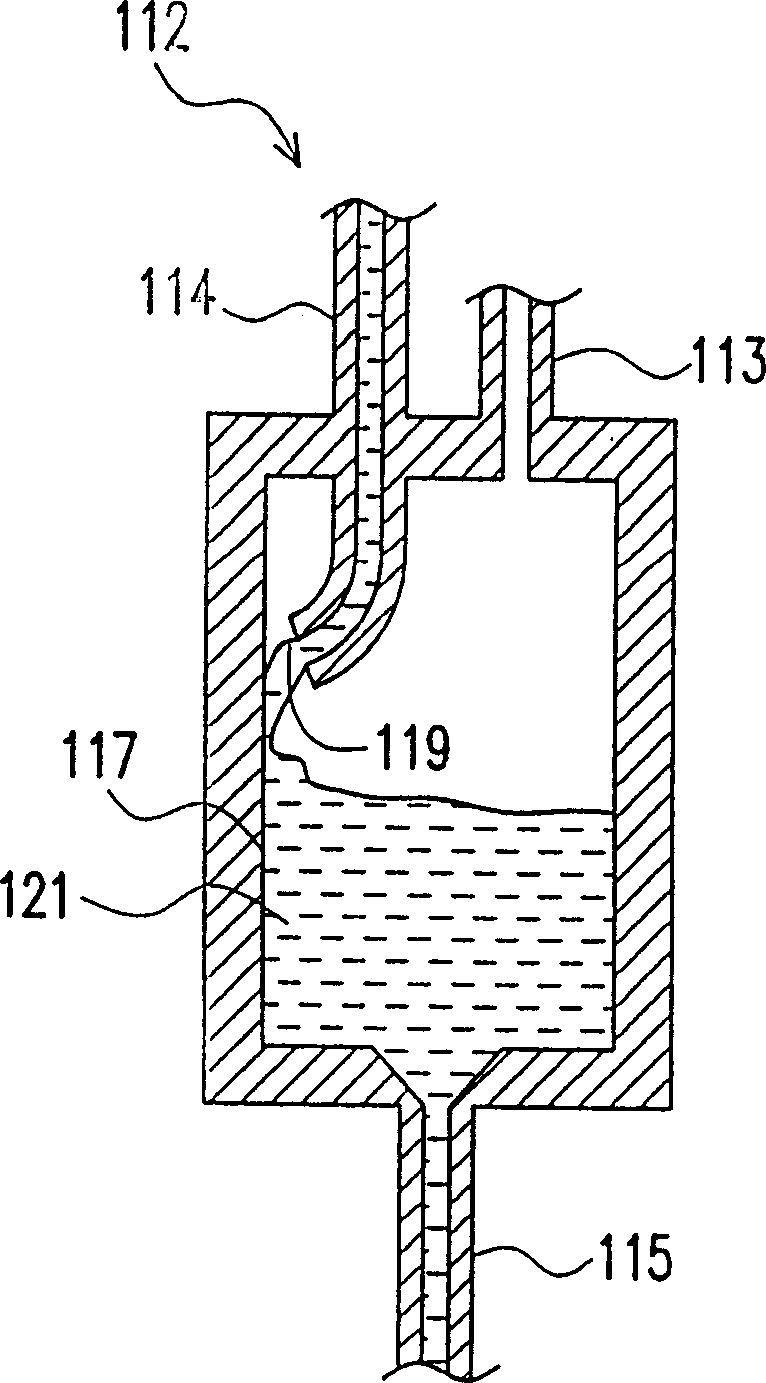

[0042] Several preferred embodiments of the photoresist supply system of the present invention will be described as follows. In a preferred embodiment, a supply system includes a negative pressure supply system and a photoresist reservoir with inlet design features to avoid microbubbles from the photoresist supply system. In order that the present invention may be fully understood, specific details are further described below. However, it must be understood that one skilled in the art can practice the invention without some or all of these specific details. In other instances, well-known technologies have not been described in detail so as not to unnecessarily obscure the present invention.

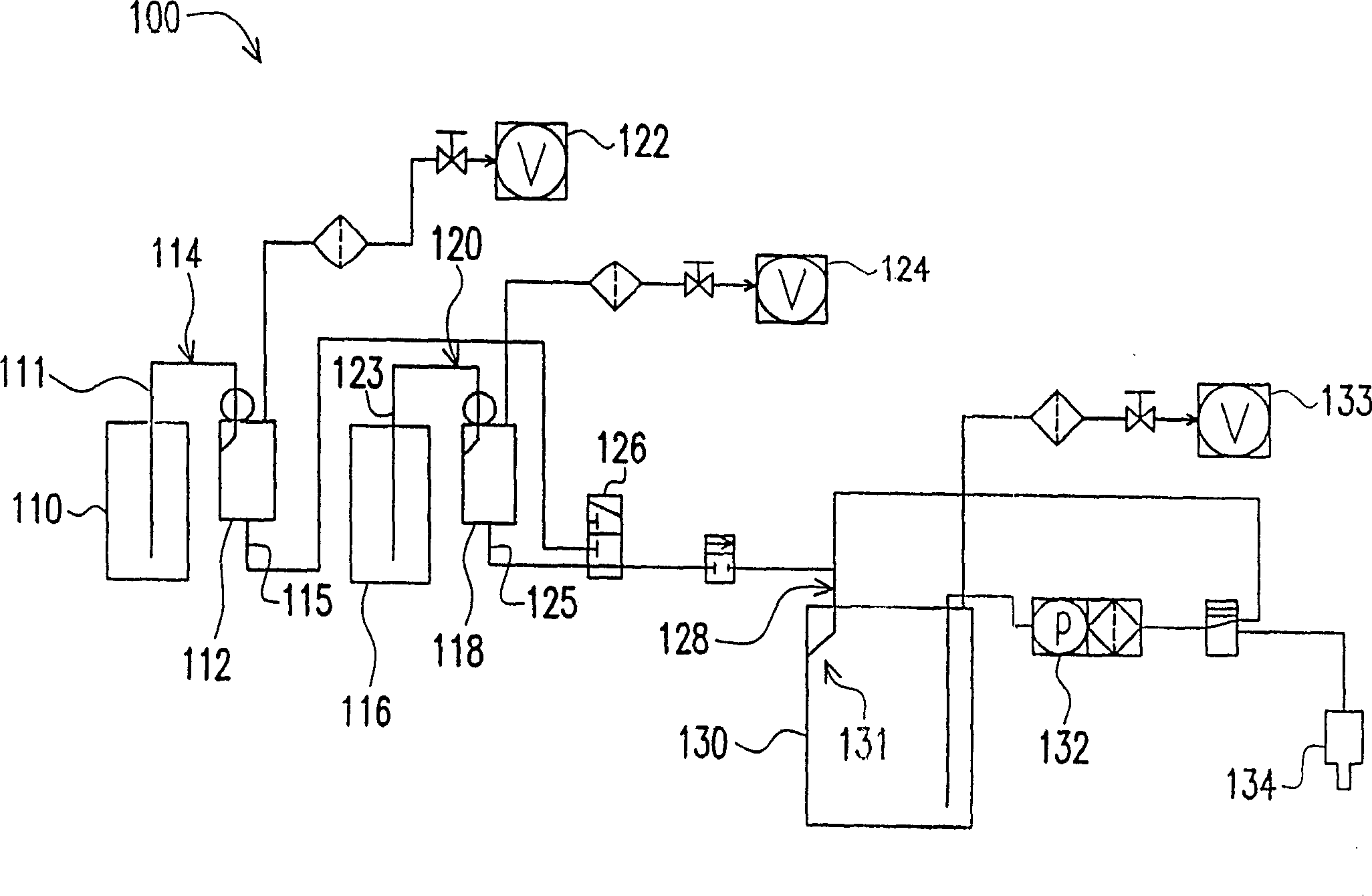

[0043] figure 1 Shown is a schematic diagram of a photoresist supply system according to a preferred embodiment of the present invention. Such as figure 1 As shown, a first storage bottle 110 is supplied to a first reservoir 112 via a first inlet conduit 114 . The second storage bottle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com