Electronic control unit acceptable for fuel cell power assembly control

An electronic control unit and powertrain technology, applied in electric vehicle charging technology, electric traction, electric vehicles, etc., can solve problems such as lack of electromagnetic compatibility quality, lack of communication modules, insufficient ECU input and output ports, etc. Achieve powerful and practical software and hardware comprehensive capabilities, strong electromagnetic compatibility quality, and high measurement accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation based on the ECU hardware and software will be described below in conjunction with the accompanying drawings.

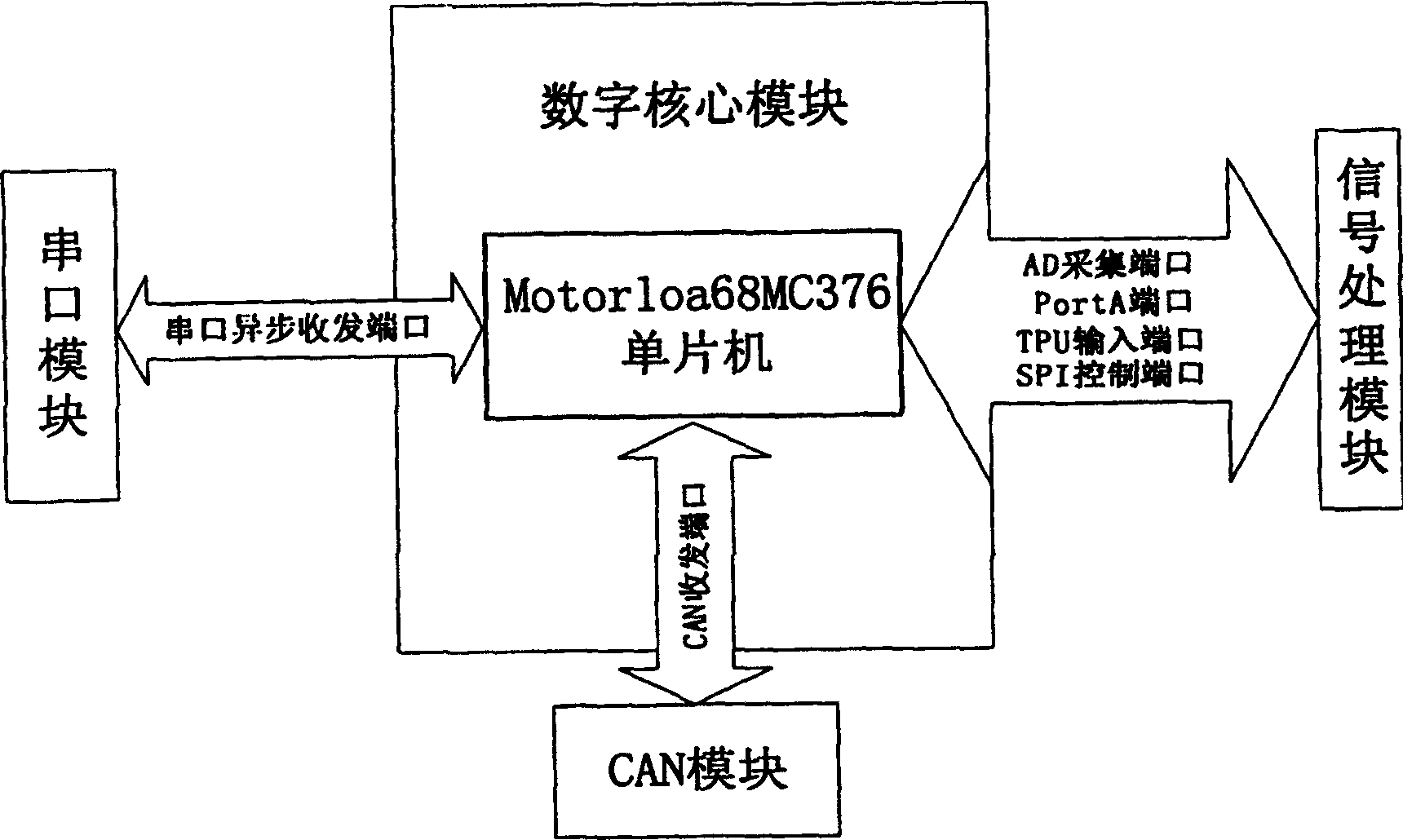

[0030] figure 1As shown, the main software and hardware structure of the ECU is as follows: the ECU hardware designed based on Motorola 68MC376 mainly includes four parts, a digital core module using Motorola68MC376 single-chip microcomputer; a signal processing module with rich input and output ports, connected to the AD of the single-chip microcomputer The acquisition port, PortA port, TPU input port, and SPI control port; the communication module with serial communication and CAN communication capabilities are connected to the single-chip microcomputer of the digital core module through the serial asynchronous transceiver port and the CAN transceiver port respectively.

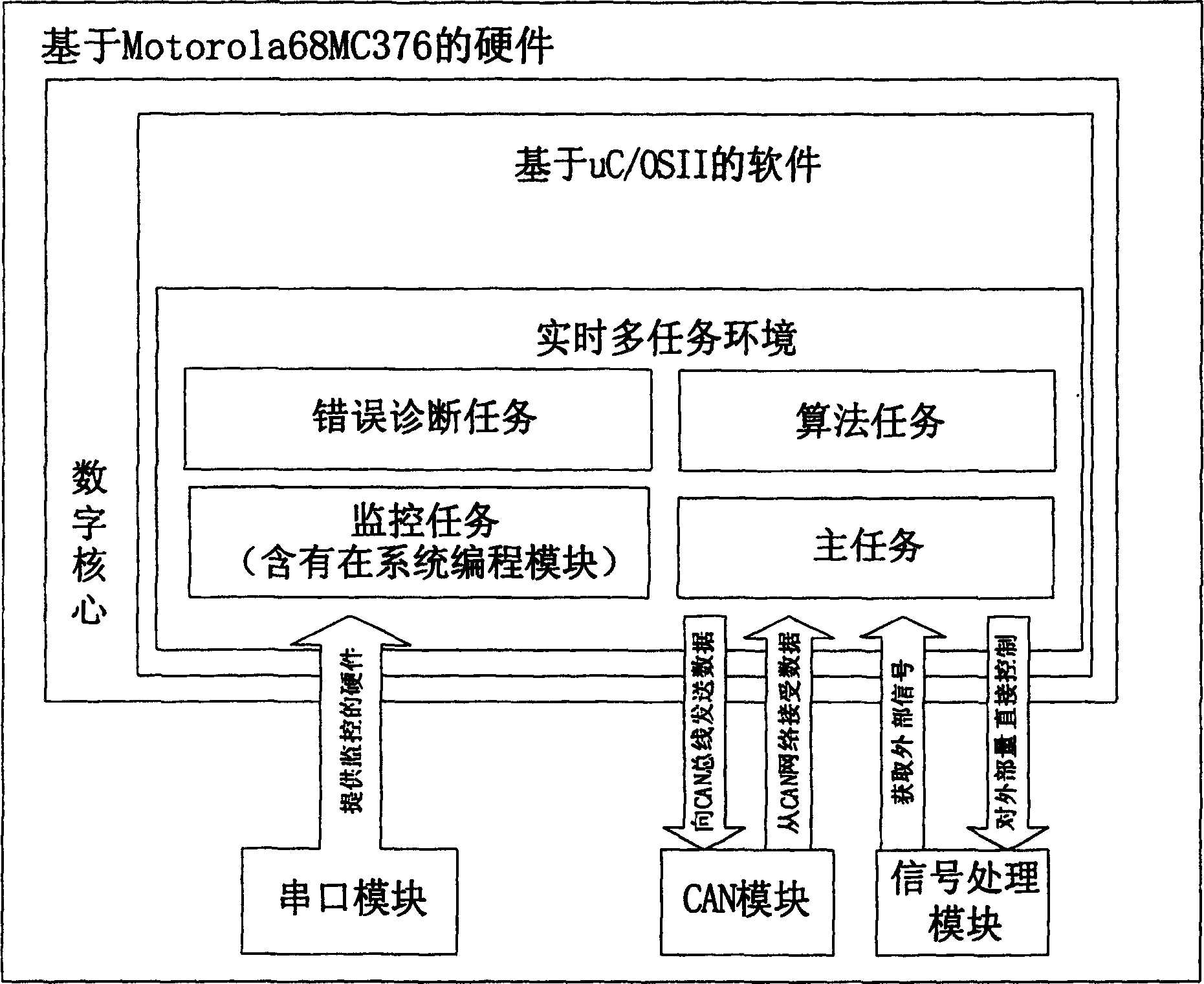

[0031] figure 2 It is a block diagram of the relationship between ECU software and hardware. The ECU software platform resides in the internal memory of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com