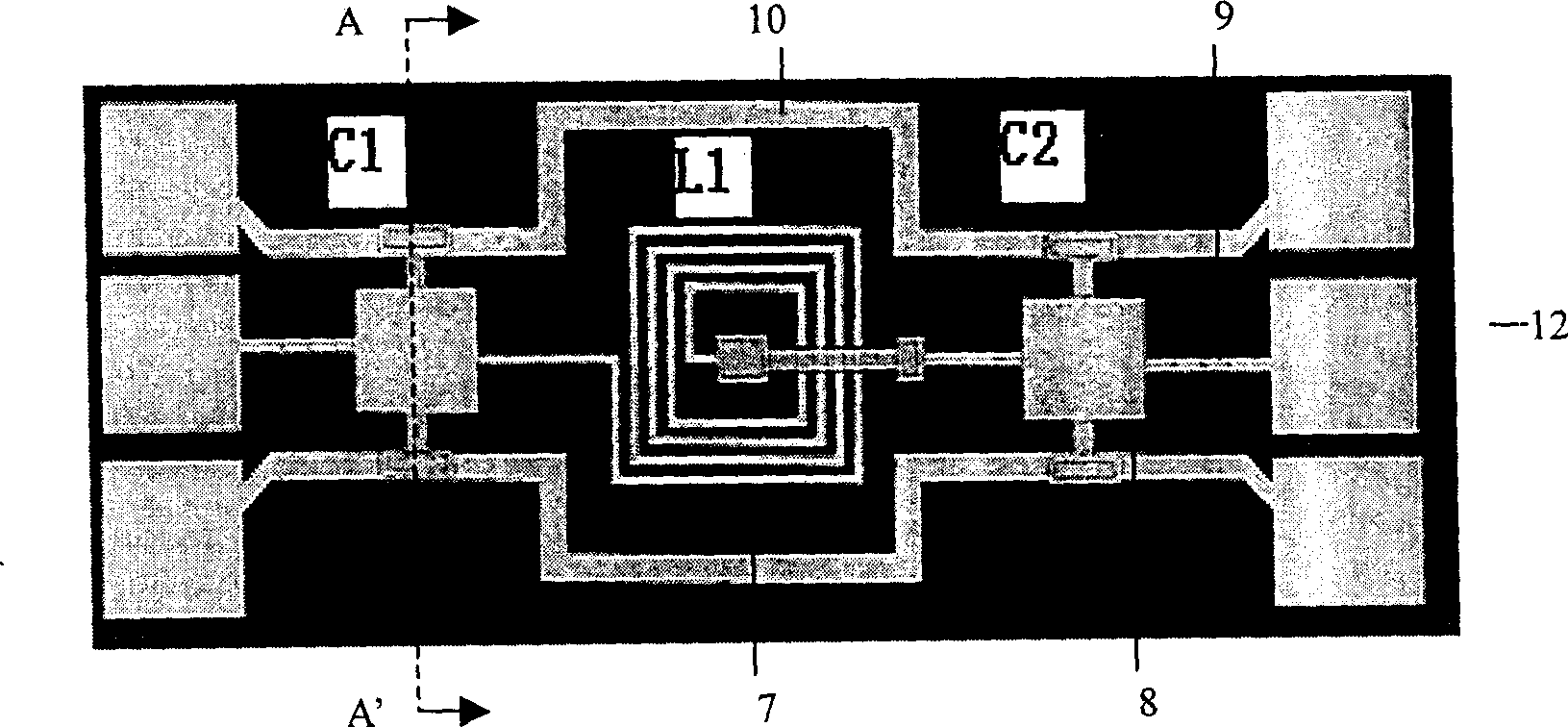

LC passive low pass flter on chip and prepn. thereof

A low-pass filter and low-pass filter circuit technology, which is applied to waveguide-type devices, circuits, electrical components, etc., can solve the problem of large insertion loss of the filter substrate, and achieve the elimination of insertion loss, small size, and production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

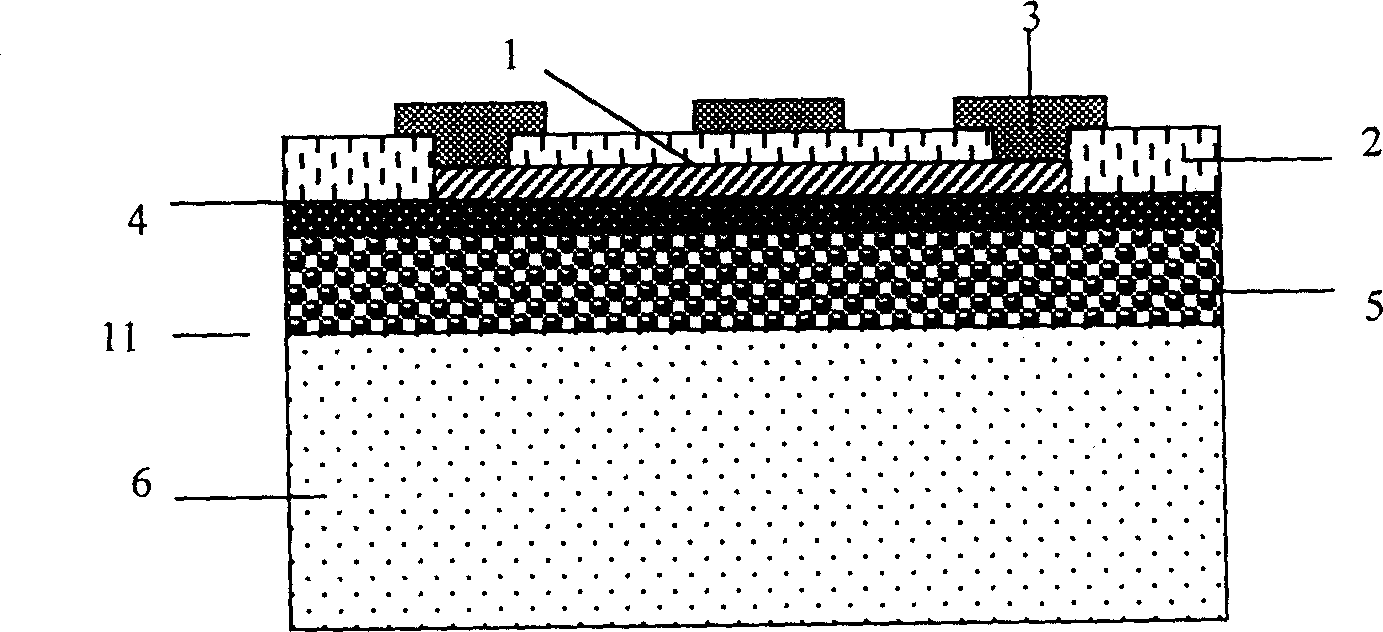

[0024] Example An on-chip LC passive low-pass filter based on oxidized porous silicon / porous silicon with the above structure prepared by the above method.

[0025] Composite substrate 11 is fabricated first. The low-resistance silicon wafer 6 is a silicon wafer with a crystal orientation of 100 and a slow resistivity ρ of 0.01Ω·cm. Immerse the low-resistance silicon wafer 6 in 40% HF ethanol solution, HF:C 2 h 5 The volume ratio of OH = 1:1, the current density of the anodic oxidation current is 25mA cm -2 . The anodizing time, that is, the etching time is 20 minutes, and a porous silicon layer 5 with a thickness of 20 μm is formed on the low-resistance silicon wafer 6 . Use the low resistance silicon chip 6 with H 2 o 2 After soaking and rinsing with deionized water, put it into an oven for drying at 200°C. Then, the porous silicon layer 5 was oxidized with wet oxygen at 1180 for 30 minutes, and an oxidized porous silicon film 4 with a thickness of 1 μm was formed on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com