Conductive rubber material with laminated structure

A layered structure, conductive adhesive technology, used in conductive materials dispersed in non-conductive inorganic materials, layered products, etc., can solve problems such as increasing the difficulty of particle manufacturing, inability to meet micro-spacing adhesion, and poor electrical conduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

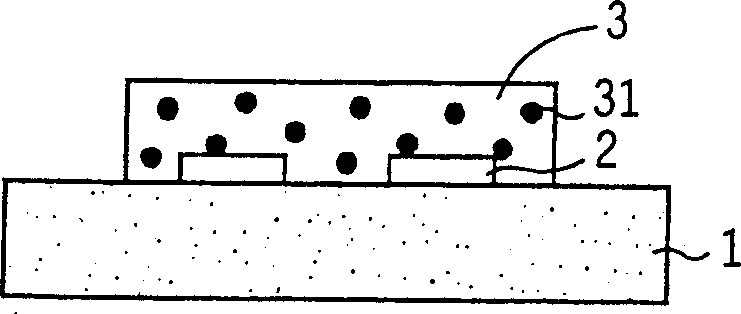

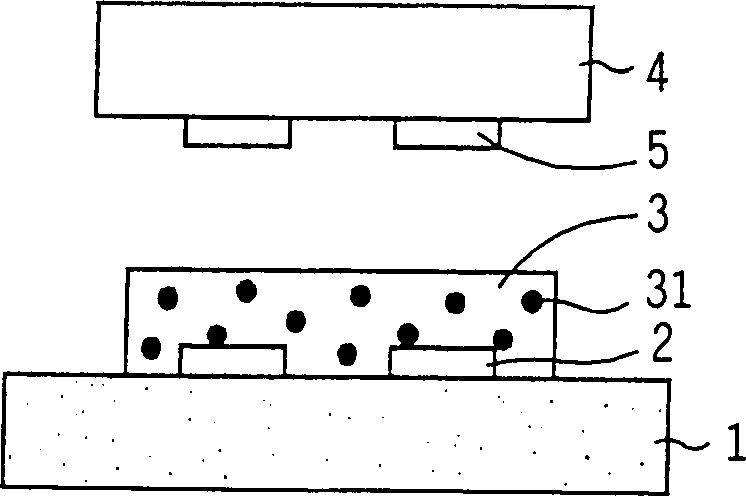

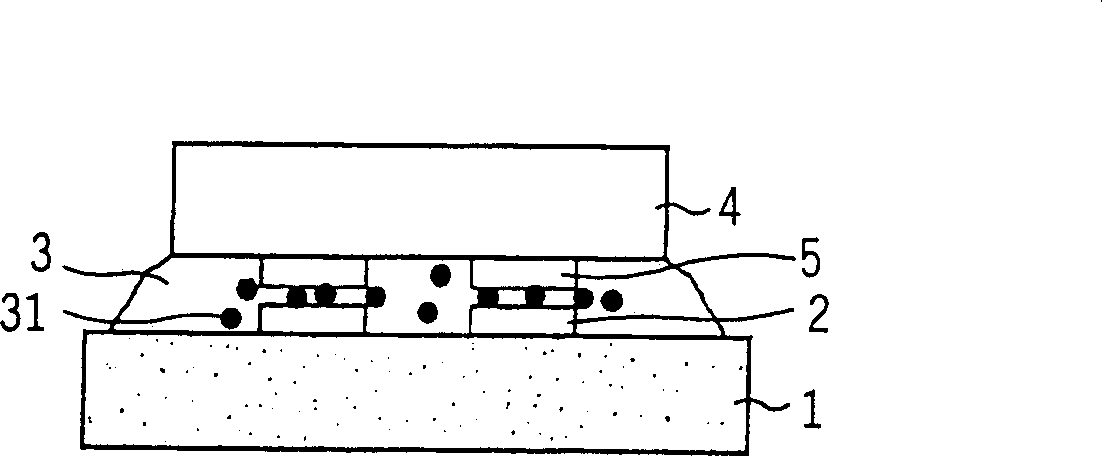

[0021] The present invention provides a layered conductive adhesive material, which spreads conductive particles on the surface of the polymer adhesive material, such as thermoplastic or thermosetting polymer adhesive material surface, so when used for crimping and connecting the drive element and the terminal on the glass substrate Finally, the connection resistance of terminal bonding can be reduced, and the purpose of adhesion can be achieved with ultra-fine pitch.

[0022] According to the conductive adhesive material with layered structure of the present invention, specifically, conductive particles are spread on both surfaces of thermoplastic or thermosetting polymer sheet adhesive material, so that the distribution density and dispersion of conductive particles on the surface of the adhesive material can be easily controlled. Evenness. And because the conductive particles are distributed on both surfaces of the adhesive material, compared with the traditional conductive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com