Battery assembly, battery support and battery

A technology of battery components and battery brackets, which is applied to battery components, electrical components, circuits, etc., can solve problems such as easy changes, difficult automatic welding, complex battery technology, etc., to achieve automatic production, avoid short-circuit defects, and automate The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

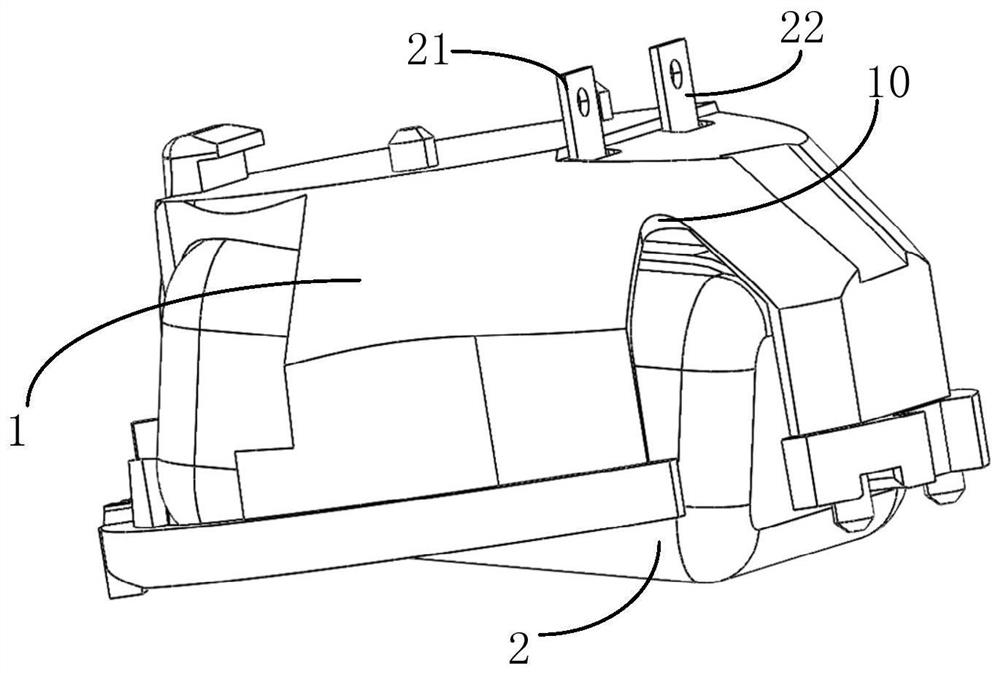

[0034] see figure 1 , figure 2 , image 3 , Figure 4 , this embodiment provides a battery assembly, including: a battery holder 1 and a battery 2 . The battery 2 includes a battery body 20 , a positive electrode sheet 21 and a negative electrode sheet 22 .

[0035] One end of the positive electrode sheet 21 is connected to the battery body 20 , and the other end extends in a first direction outside the battery body 20 .

[0036] One end of the negative electrode sheet 22 is connected to the battery body 20 , and the other end extends in a second direction outside the battery body 20 ; the negative electrode sheet 22 is isolated from the positive electrode sheet 21 .

[0037] The negative electrode sheet 22 and the positive electrode sheet 21 are rigid, and the extending direction of the extending end of the positive electrode sheet 21 and the extending direction of the extending end of the negative electrode sheet 22 are kept constant.

[0038] The battery holder 1 incl...

Embodiment 2

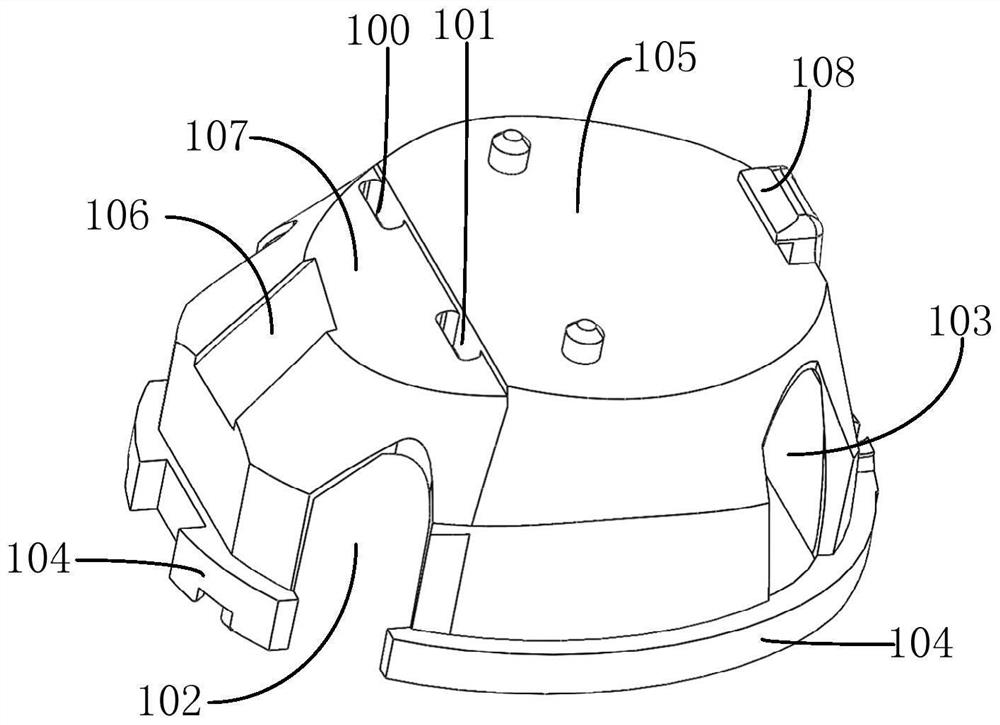

[0053] see figure 1 , figure 2 , image 3 , Figure 4 , the present embodiment provides a battery holder 1 , including a storage compartment 10 for accommodating and installing a battery body 20 ; the storage compartment 10 includes an extension hole 100 for a positive electrode sheet and an extension hole 101 for a negative electrode sheet.

[0054] It should be noted that one end of the positive electrode sheet 21 is connected to the battery body 20 , and the other end extends in a first direction outside the battery body 20 to extend out of the protruding hole 100 of the positive electrode sheet.

[0055] It should also be noted that one end of the negative electrode sheet 22 is connected to the battery body 20 , and the other end extends in a second direction outside the battery body 20 to extend out of the protruding hole 101 of the negative electrode sheet.

[0056] It should also be noted that the negative electrode sheet 22 is separated from the positive electrode ...

Embodiment 3

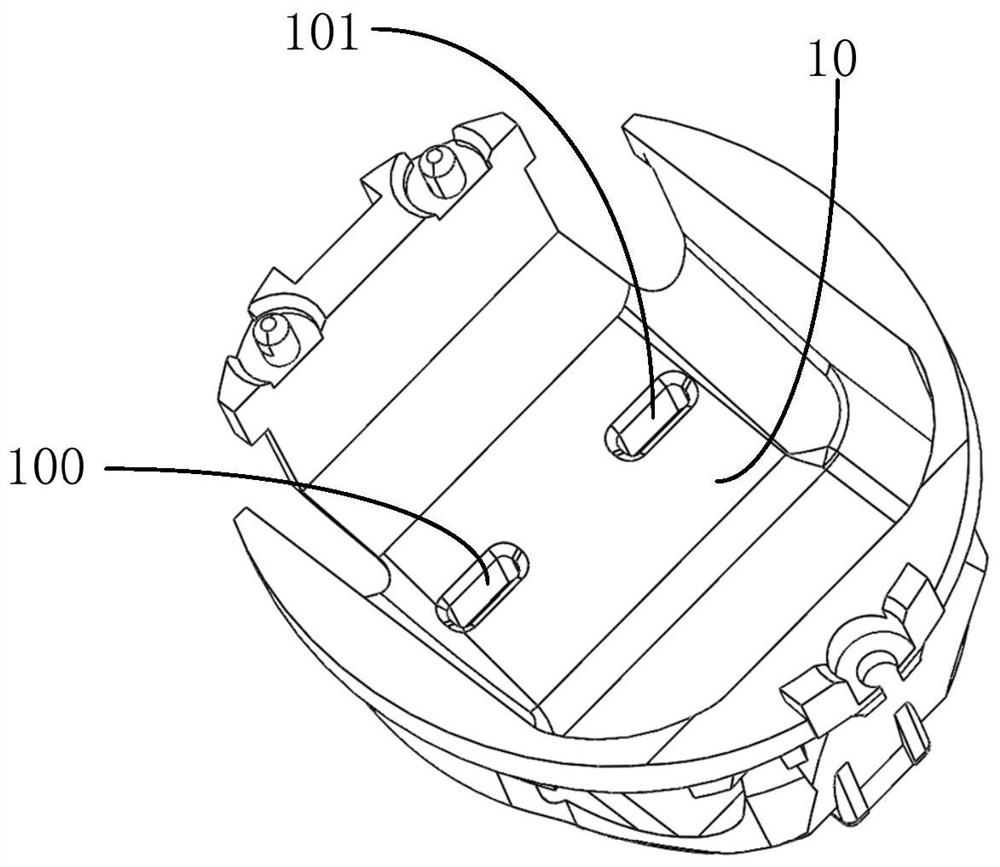

[0068] see figure 1 , figure 2 , image 3 , Figure 4 , this embodiment provides a battery 2, including a battery body 20, a positive electrode sheet 21 and a negative electrode sheet 22;

[0069] One end of the positive electrode sheet 21 is connected to the battery body 20, and the other end extends in a first direction outside the battery body 20; one end of the negative electrode sheet 22 is connected to the battery body 20, and the other end extends in a second direction outside the battery body 20; Positive plate 21 isolation setting;

[0070] The negative electrode sheet 22 and the positive electrode sheet 21 are rigid, and the extending direction of the extending end of the positive electrode sheet 21 and the extending direction of the extending end of the negative electrode sheet 22 are kept constant.

[0071] Further, the positive electrode sheet 21 includes a first segment 210 and a second segment 211; the first segment 210 and the second segment 211 are integr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com