Dynamic cellular automaton method for simulation of photoresist three dimensional etching process

A cellular automaton, etching process technology, applied in the direction of computer for chemical processing process, microlithography exposure equipment, simulation process for specific applications, etc., can solve the simulation method that is difficult to achieve stability, simulation speed and Accuracy requirements and other issues, to achieve the effect of fast operation speed, reduced simulation time and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] specific implementation plan

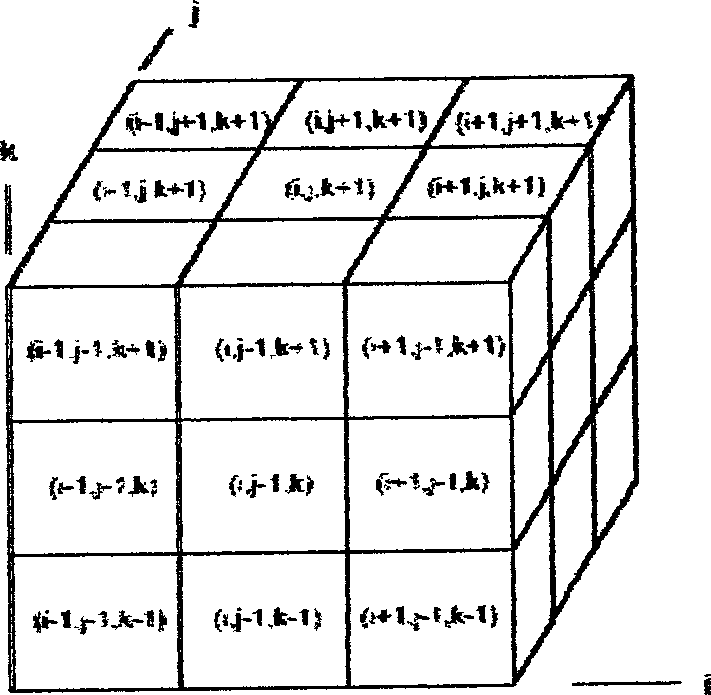

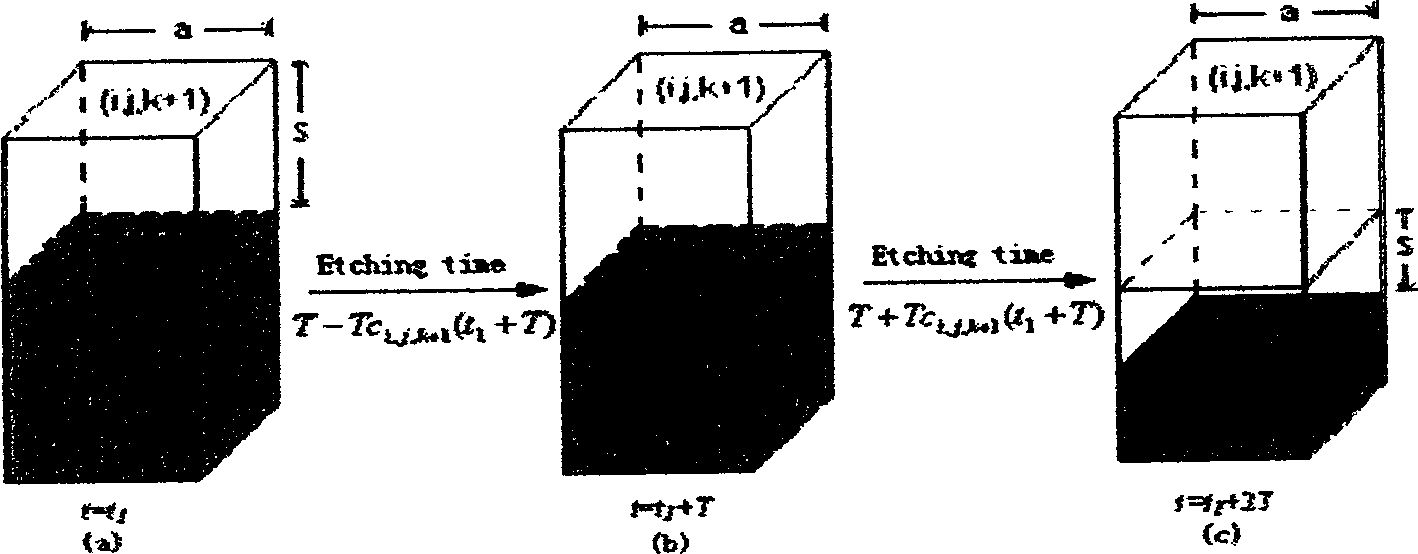

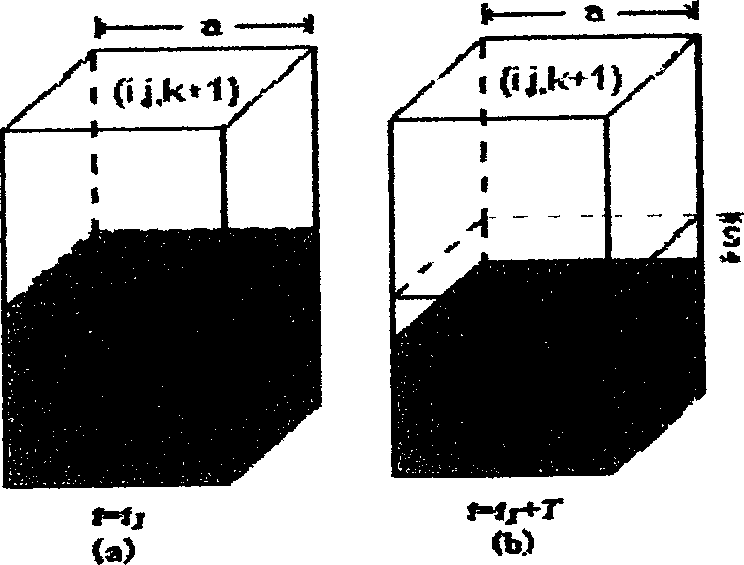

[0027] In the present invention, the photoresist to be etched is subdivided into an array of small cubes with a side length a, and each cube is used as a cell of a cellular automaton. During the cell etching process, a certain moment t corresponds to cell state C i,j,k (t) is defined as the etched volume V of the cell at this time e (t) and the whole cell volume V c The ratio of:

[0028] C i , j , k ( t ) = V e ( t ) V c - - - ( 1 )

[0029] The etching rate R of each cell can be obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com