Heat lamination of dry photoresist film onto board for printed circuit

A circuit board, thermal lamination technology, applied in printed circuits, use/removal methods of circuit masks, printed circuit manufacturing, etc., can solve problems such as slow running process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

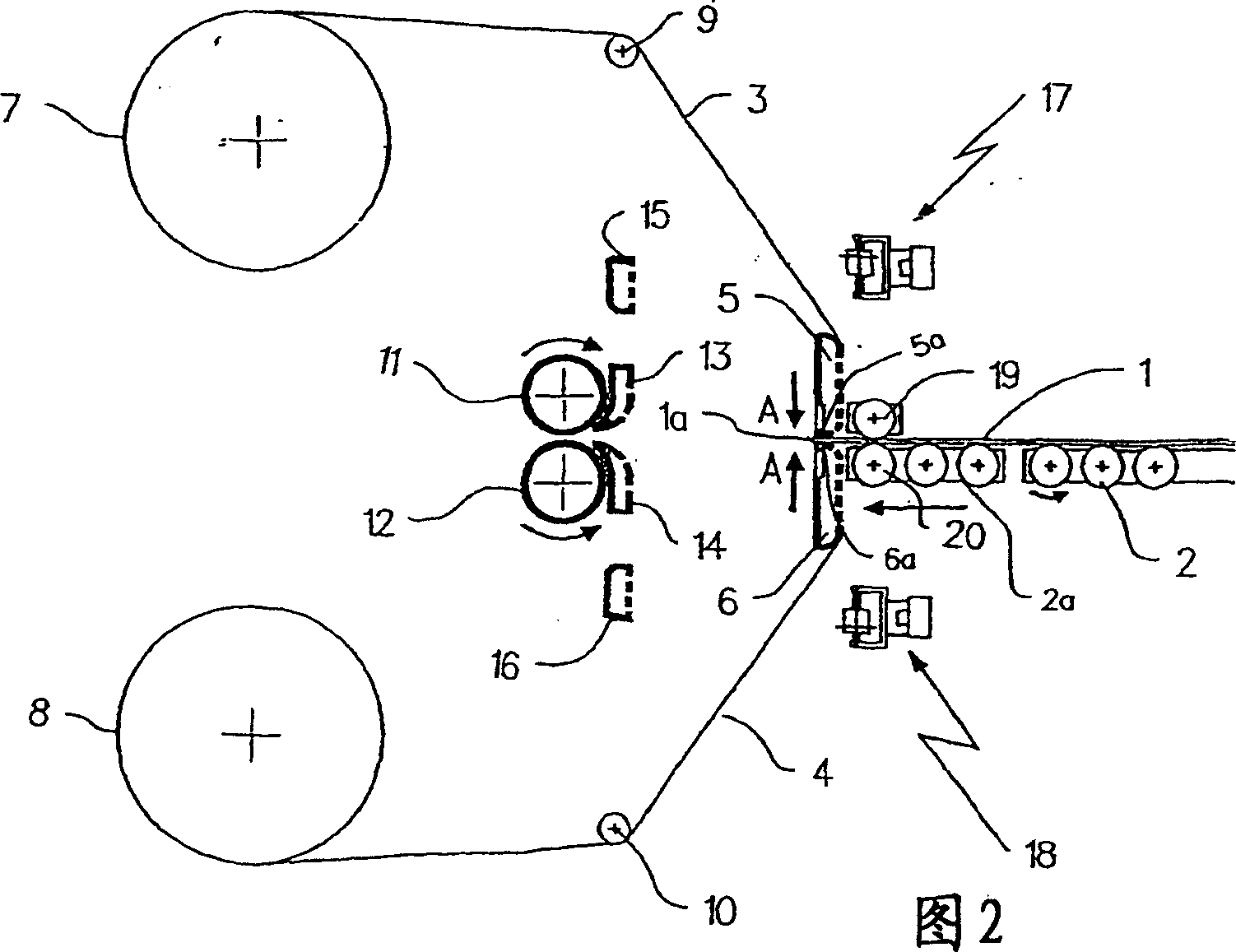

[0027] The various stages of the entire stroke (or cycle) of the automatic laminator of the present invention are schematically represented in the appended figure 1 to 7.

[0028] In the described examples, it is assumed that a dry photoresist film is placed on both surfaces of the printed circuit board, as this is the most common case. The machine of the invention is of course also suitable for placing dry photoresist film onto only one surface of the circuit board by simply stopping the lamination of the relevant mechanism relative to the dry photoresist film on the other side of the circuit board.

[0029] figure 1 Represents the main components of an automatic laminator of the present invention that is idle or waiting for the arrival of new circuit boards 1, where the circuit boards are usually preheated to a certain temperature.

[0030] The circuit board 1 is finally moved towards the lamination section of the laminator by means of a conveyor 2 .

[0031] During the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com