1300 MPa-grade high-elongation low-delay cracking sensitivity hot forming steel and production method thereof

A high-elongation, hot-formed steel technology, applied in the production of hot-formed steel and hot-formed high-strength steel, can solve problems such as damage and energy-absorbing effect decline, achieve good application prospects and economic benefits, improve elongation, and high elongation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

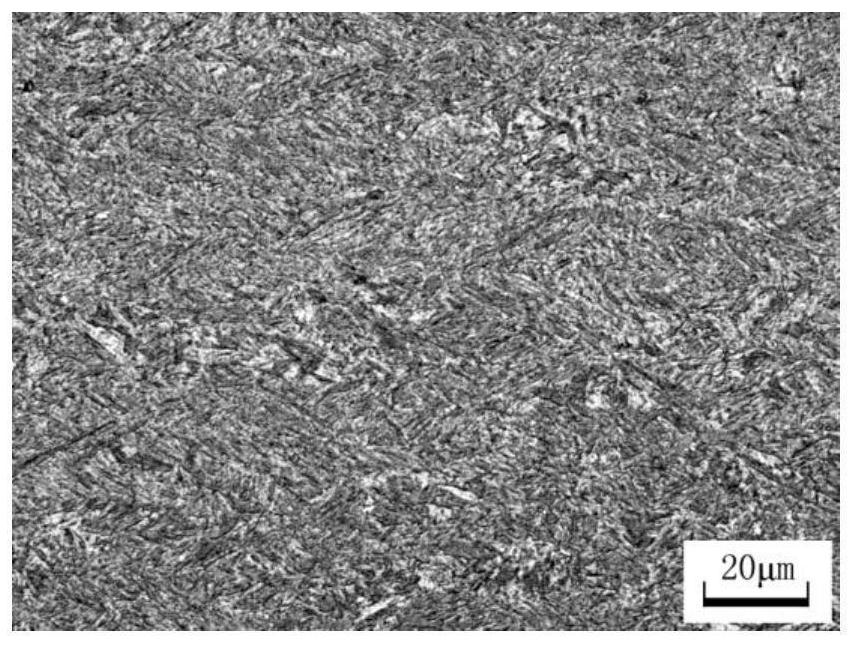

[0033] Specific embodiments of the present invention are described in detail below, which, as a part of the description, illustrate the principle of the present invention through examples, and other aspects, features and advantages of the present invention will become clear through the detailed description.

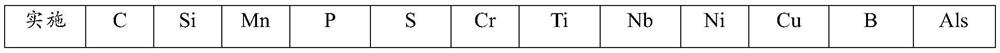

[0034] The chemical composition of the steel plate is shown in Table 1 below.

[0035] Table 1 The chemical composition value list (wt%) of each embodiment of the present invention and comparative examples

[0036]

[0037]

[0038] The main technology of each embodiment of the present invention and comparative example of table 2

[0039]

[0040] The conventional mechanical properties of the test steel and the comparison steel were compared, and the results are shown in Table 3; at the same time, the delayed cracking performance of the test steel and the comparison steel was compared, and the SSRT slow tensile test was carried out in 0.1mol / L HCl, and the tensil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com